Aizenay General and Technological High School

Last modified by the author on 15/02/2023 - 12:31

New Construction

- Building Type : School, college, university

- Construction Year :

- Delivery year : 2022

- Address 1 - street : 8 rue Albert Camus 85190 AIZENAY, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 8 687 m2

- Construction/refurbishment cost : 20 232 621 €

- Number of Pupil : 620 Pupil

- Cost/m2 : 2329.07 €/m2

Certifications :

-

Primary energy need

24.6 kWhep/m2.an

(Calculation method : RT 2012 )

This project won the Student Prize at the Green Solutions Awards France 2022-2023.

For its general and technological high school in Aizenay in Vendée, the Pays de la Loire Region has chosen to build an unprecedented low-carbon structure.

Biosourced materials, architectural sobriety, respect for biodiversity, promotion and creation of short circuits… So many assets that reflect a real strong social, economic and environmental commitment of an entire construction industry in Pays de la Loire.

The target values of the various "low carbon" labels have been achieved: level 3 of the biosourced building label, E3C2 label and NF HQE Sustainable Building certification at the "Excellent" level for the design phase.

The establishment, with a capacity of 620 students with the possibility of extending to 830 students, has a day school for general and technological education, an administration, school life premises, a catering service for 840 rations, a gymnasium and 5 staff accommodation.

Architectural sobriety

- Simple architectural forms

- 100% wood frame resting on a concrete base

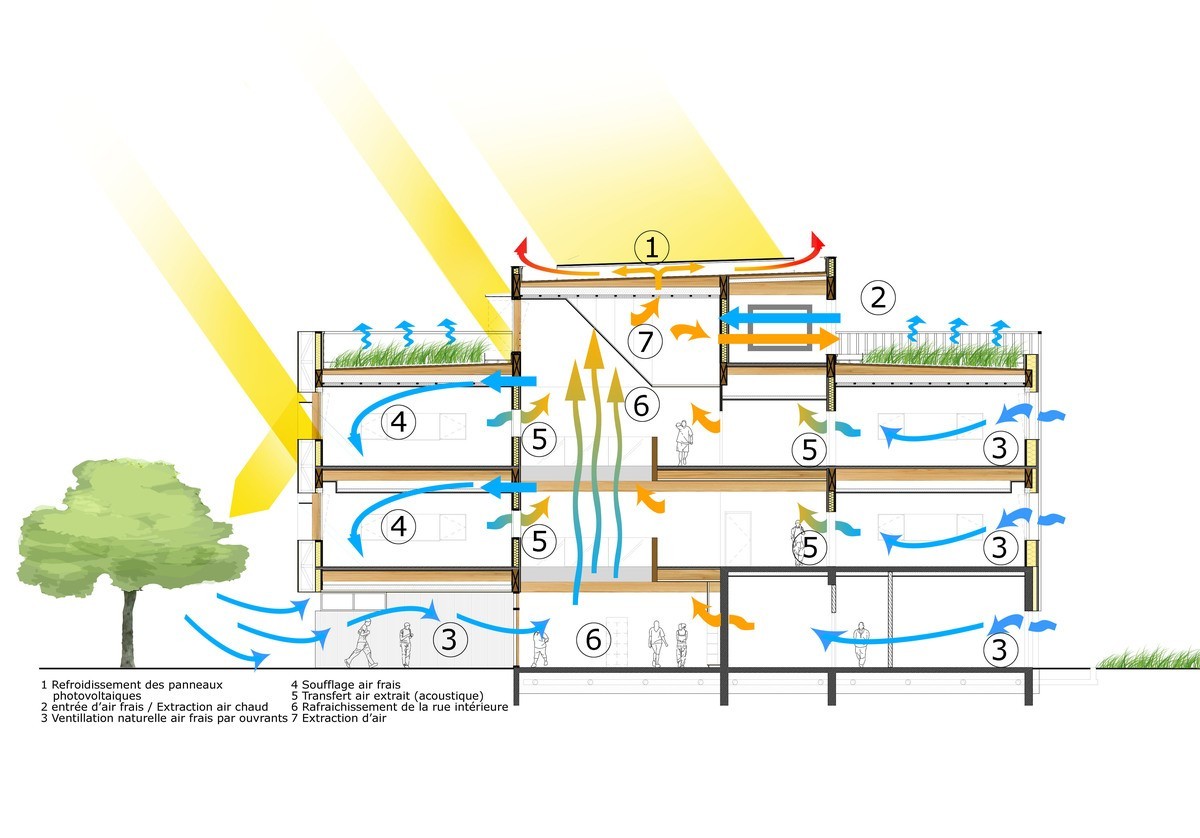

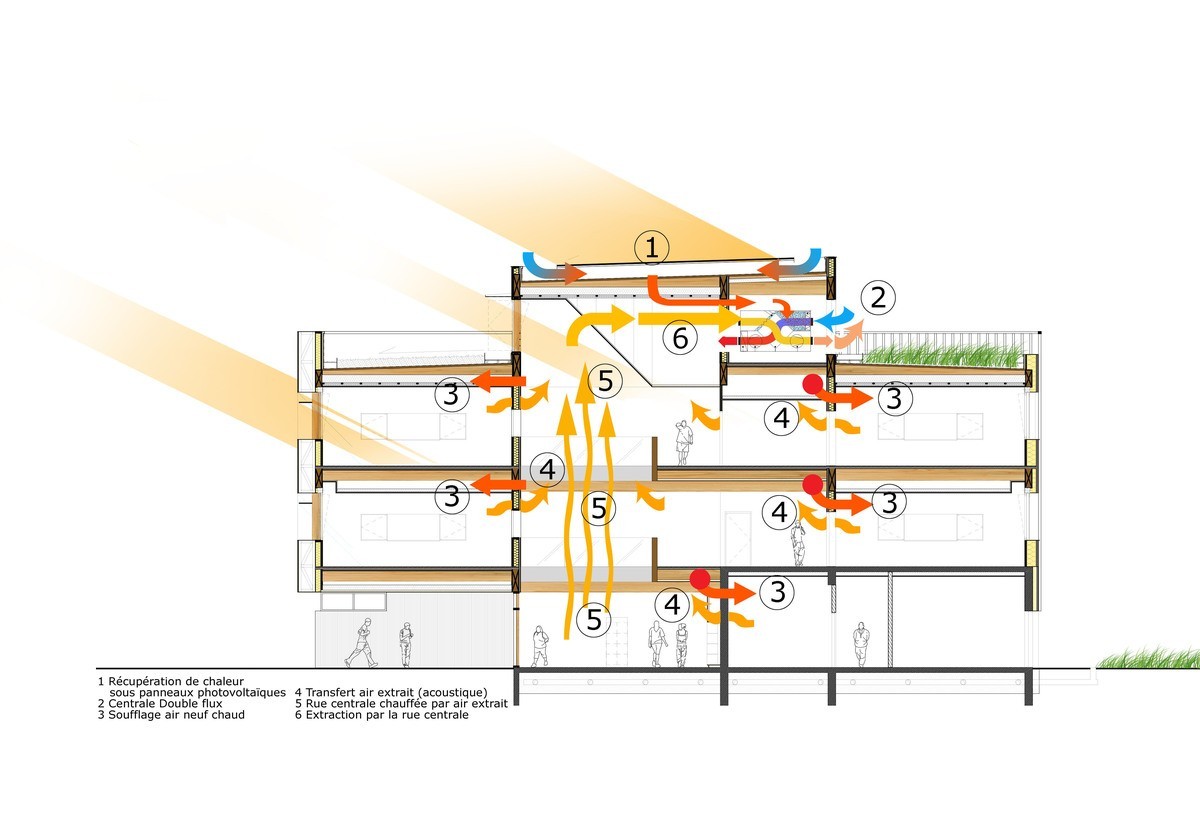

- Large interior street serving three levels

- Large interior street heated and ventilated naturally, dressed in wood

- Zinc cladding with standing seam to the South and West and wood cladding to the East and North

- 200-seat multipurpose room that can operate independently of the high school

- Collective kitchen for 840 rations/day and dining room open to the landscape thanks to a terrace

- Technical sobriety, DF ventilation (attic rooms, wood/gas boiler room, LED lighting without dimming)

Short circuits/biosourced materials

- 12,000 bales of straw for insulation obtained with the help of the Collectif Paille Armoricain, 9 Vendée farmers via the company Profibres (85).

- 90 kg of biosourced materials per m2 (instead of 38 kg/m2 to reach level 3 of the biosourced building label).

- Hemp-based interior wall insulation manufactured by the Vendée agricultural cooperative La CAVAC (Biofib).

- Algo paint produced in Brittany from 100% natural algae.

- Low-carbon concrete from Vendée, Hoffmann Green Cement Technologies, for the wall in the duty room.

- Prefabricated wooden structure by the Vendée company LCA with machined wood at Piveteau Bois (85).

Biodiversity/outdoor spaces

- Pond of the three mills valued in an educational and ecological interest.

- Planting of 60 trees, 350 shrubs, perennial beds, natural meadows.

- Bocage hedges created or recreated with rustic and local species.

- Landscaped retention basin for rainwater planned on the West side.

- League for the Protection of Birds associated with the project: Nesting boxes, nests and lodgings installed for the preservation of small fauna and different species of birds.

- Establishment of differentiated management to provide a refuge for local wildlife.

If you had to do it again?

Further reflection would be carried out on re-use materials and recycling.

Natural light in the interior street would also be better studied.

See more details about this project

https://www.lca-construction.fr/construction-en-cours-du-lycee-d-aizenay/https://www.lesechos.fr/pme-regions/pays-de-la-loire/le-lycee-daizenay-un-chantier-bois-paille-hors-norme-1410587

BIM approach

The Pays de la Loire Region is currently in charge of a heritage of more than 2 million square meters, consisting mainly of high schools and administrative buildings. To help it in the management of its assets and to promote the use of these new methods, the Region asked for the construction project of the new high school of Aizenay the realization of a "CWF (completed works file) BIM", articulated around a dematerialized Executed Works File and digital models of each building. Some data expected by the Region, such as details on the materials used or data specific to the Direction du Patrimoine Immobilière de la Région for its internal management of the estate, have also been integrated into the objects of the digital models. For the large technical equipment of the project, more complete and structured information was expected to link with their maintenance management software.

During the design studies, each design office produced a model of the trades under its responsibility (architecture, structure, HVAC and plumbing, electricity and kitchen). On site, in line with the basic missions of the market, the companies of the structural lots (the structural work and the wooden frame) as well as the technical lots (HVAC and plumbing, electricity and kitchen) took over the modeling and the information of the data expected. For the secondary lots, the architect kept control of the creation of the digital model.

All of this work enabled us to provide the contracting authority with a model of each tradesman as well as a model compiled of the whole for each building, in accordance with its expectations and “as built”. Finally, the large technical equipment as well as their characteristics present in the digital models will make it possible to link the data with their internal asset management solutions and thus have the continuous updating of this one.

Photo credit

Charles Durand

Contractor

Construction Manager

Stakeholders

Other consultancy agency

EGIS

Aurélien Chené

https://www.egis-group.com/frstructure, fluids, economy, external works consultancy agency

Assistance to the Contracting Authority

Collectif Paille Armoricain

Francois-Xavier Vandeville

https://armorique.constructionpaille.frConstruction manager assistant - straw

Assistance to the Contracting Authority

BEHI ingénierie

Jérémie Proux

http://www.behi.fr/developpement-durable/amo-environnement/Construction manager assistant - environment

Other consultancy agency

CRR Ingénierie

Jihen Jallouli

https://crr-architecture.comThermal consultancy agency HQE

Designer

CRR Architecture

Vincent Hervieu

https://crr-architecture.comBIM management, architecture, landscape

Structures calculist

Salto Ingénierie

Kevin Marpeau

http://www.salto-ingenierie.comAcoustic

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 24,60 kWhep/m2.an

- Heating: 2.5

- DHW: 2.5

- Lighting: 10.2

- Vetnilation: 9.2

- Distribution auxiliaries: 0.3

Real final energy consumption

139,20 kWhef/m2.an

Envelope performance

- 0,80

- 1,00

More information

The re-entry of the occupants took place in September 2022, we do not yet have information on actual consumption and performance.

Systems

- Individual gas boiler

- Water radiator

- Wood boiler

- Individual gas boiler

- Wood boiler

- No cooling system

- Single flow

- Double flow heat exchanger

- Wood boiler

- 7,00 %

Smart Building

Biodiversity approach

- Plantation of 60 trees, 350 shrubs, perennial beds, natural meadows

- Bocage hedges created or recreated with rustic and local species

- Landscaped retention basin for rainwater planned on the West side

- League for the Protection of Birds associated with the project: nesting boxes, nests and lodgings installed for the preservation of small fauna and different species of birds

- Implementation of differentiated management to leave a refuge for local wildlife

- Preservation of the pond

- Replanting of a bocage hedge to replace the destroyed one

- Permeable exterior covering (walkways, student playground)

- Installation of nesting boxes and shelters for insects

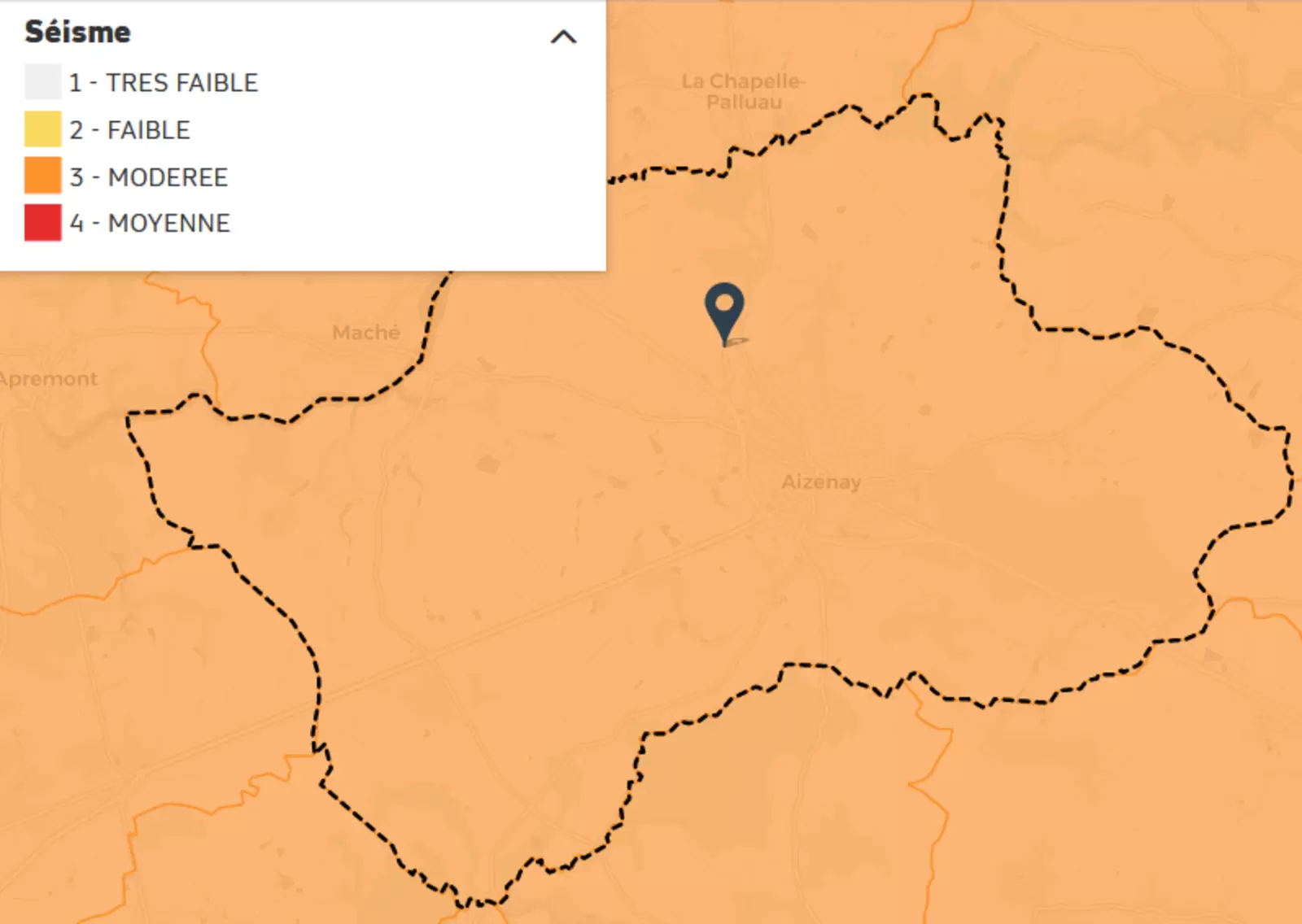

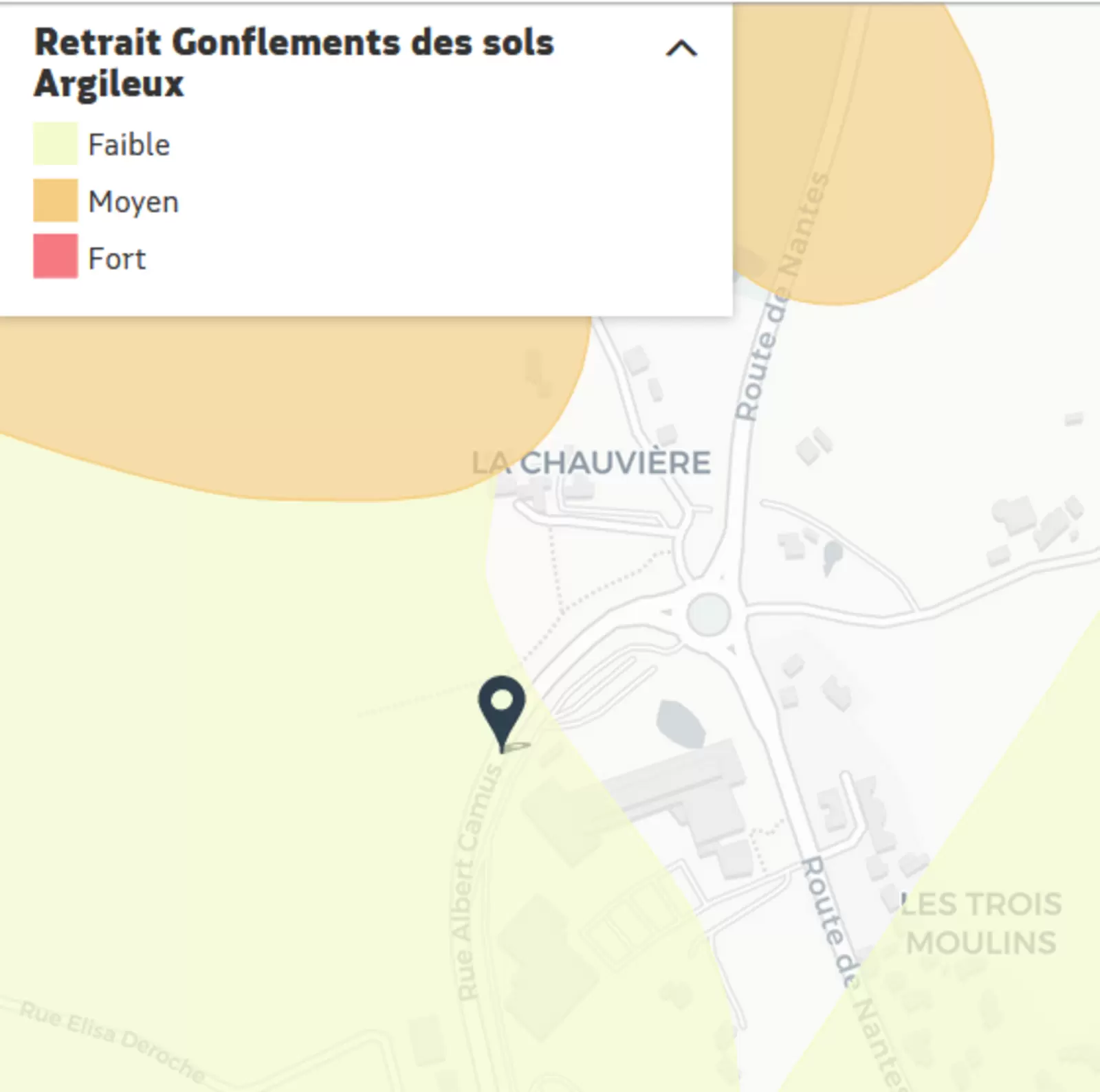

Risks

- Flooding/Fast Recession

- Landslide

- Wind / Cyclone

- Heatwave

- Strong insulation with biosourced materials (straw + hemp) known for their thermal phase shift.

- Loggia effect to protect exterior joinery.

- Students' courtyard protected from the prevailing westerly winds.

- Natural ventilation by the interior street.

- Free cooling possible by air handling units

Urban environment

- 37 724,00 m2

- 46,00 %

- 10 900,00

Product

Straw insulation thanks to the Armorican straw collective via Profibres

Profibres

https://www.profibres.frFinishing work / Partitions, insulation

R = 6,91 m2K/W

Hemp produced by the Vendée agricultural cooperative La CAVAC

La CAVAC

https://www.coop-cavac.frFinishing work / Partitions, insulation

R = 1,154 m2K/W

Algo Paint produced in Brittany from 100% natural algae.

Peinture Algo

https://www.peinture-algo.frFinishing work / paints, mural, wallcoverings

Low-carbon concrete from Vendée Hoffmann Green Cement Technologies

Ciments Hoffmann

https://www.ciments-hoffmann.comStructural work / Structure - Masonry - Facade

https://www.ciments-hoffmann.fr/actualites/realisations-beton-bas-carbone-lycee-aizenay/

Nesting boxes, nests and lodgings installed for the preservation of small fauna

Valliance

valliance[a]outlook.fr

https://www.valliance-nature-69.frManagement / Others

Construction and exploitation costs

- 20 232 621 €

Energy bill

- 100 000,00 €

Social economy

Additional information (PDF documents)

Water management

- 1 000,00 m3

- 860,00 m3

Indoor Air quality

Comfort

Quality of life and services

The interior street was designed to encourage meeting and exchange.

General infos

As much as possible, the contracting authority and the prime contractor have favored biosourced materials and the territorial ecosystem, thus taking advantage of the multiple benefits for the environment, the economy and the revitalization of the territories. Straw, in particular, the flagship material for this project, was obtained with the help of the Collectif Paille Armoricain (35), nine Vendée farmers and the Profibres company for storage and packaging (85).

- 90 kg of biosourced materials per m2 (instead of 38 kg/m2 to reach level 3 of the biosourced building label)

- The hemp-based insulation produced by the Vendée Biofib

- Algo paint produced in Brittany from 100% natural algae

- Low-carbon concrete from Vendée, Hoffmann Green Cement Technologies, for the wall in the duty room

- The prefabricated framework by the Vendée company LCA with machined wood at Piveteau Bois (85)

Ic Energy

45,10 KgCO2 /m2

Ic Construction

1 000,00 KgCO2 /m2

Initiatives promoting low-carbon mobility

Creation of a bicycle and scooter room.

GHG emissions

- 4,30 KgCO2/m2/an

- 50,00 année(s)

Life Cycle Analysis

Reasons for participating in the competition(s)

Le lycée d’Aizenay est le résultat d’une démarche exigeante de performance environnementale. Autant que possible, le maître d’ouvrage et le maître d’oeuvre ont privilégié les matériaux biosourcés et l’écosystème territorial profitant ainsi des bénéfices multiples pour l’environnement, l’économie et la dynamisation des territoires.

Cet établissement représente l’un des bâtiments les plus importants en Europe utilisant ce procédé constructif bois/paille. Il se distingue également par sa sobriété architecturale ainsi que par ses espaces extérieurs valorisés dans un intérêt pédagogique et écologique.

Notre candidature vise à valoriser des solutions durables, concrètes, reproductibles et plus globalement l’engagement de tout un territoire en faveur de la neutralité carbone.

Building candidate in the category