9 Percier - Paris

Last modified by the author on 21/03/2023 - 09:10

Renovation

- Building Type : Office building < 28m

- Construction Year : 1928

- Delivery year : 2022

- Address 1 - street : 9 avenue Percier, 1er étage 75008 PARIS, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 750 m2

- Construction/refurbishment cost : 280 000 €

- Number of Work station : 100 Work station

- Cost/m2 : 373.33 €/m2

Certifications :

-

Primary energy need

162.84 kWhep/m2.an

(Calculation method : Other )

This project won the Circular Economy Prize of the Green Solutions Awards France 2022-2023.

Our project is a responsible and biophilic showcase at the service of employees, which responds to the challenges of circular economy, reuse, quality of life, transversality and conviviality.

Several elements have led us to reorganize our workspaces:

1. Changes in our working methods, due to:

- Developing an internal hybrid working methods and with our customers and partners, post-COVID accelerating and developing teleworking.

- The ever-increasing added value of the transversality of our businesses in terms of business interest for ARP Astrance employees and in the context of carrying out our missions.

Our actions have made it possible to find a balance between spaces that is promoting the operational cross-functionality of ARP Astrance's businesses, collective intelligence, exchanges and which make it possible to accentuate synergies, while respecting everyone's needs.

2. Our desire for a redevelopment with the smallest possible carbon and material footprint, and exemplary in terms of the circular economy, within a controlled budget

This resulted in the reuse of a maximum of existing elements in situ and the choice of materials resulting from reuse

Our actions have reduced the carbon footprint of our refurbishments by 80%.

3. Our desire to strengthen the quality of life at work through workspaces: social ties, biophilia, sanitary quality of spaces

This resulted in:

- Spaces that promoting social ties;

- A nap area equipped with a rest bench associated with relaxation software;

- Choice of materials with low health impact such as the new carpet used with the Declare label and low VOC emissions (MILLIKEN Partner).

Our pilot project reflects our know-how and business expertise. It allows us to highlight our skills and our vision in order to replicate this project for and with our customers.

See more details about this project

https://arp-astrance.com/references.html?view=project&id=109:arp-astrance-design-circulaire-et-space-planning-paris&catid=119:amenagement-designhttps://www.linkedin.com/feed/update/urn:li:activity:7029461178376409089

Photo credit

Olivier Martin Gambier

Contractor

Construction Manager

Stakeholders

Company

Bouygues Energie Services

Alain CASULE - a.casule[a]bouygues-es.com

https://www.bouygues-es.fr/General contractor for the interior refurbishment of our offices

Manufacturer

KATABA

Florent SEDENO - f.sedeno[a]kataba.fr

https://kataba.fr/pages/notre-histoireContracting method

Other methods

Type of market

Not applicable

Other type of market

Private

Allocation of works contracts

Build and sell construction

Energy consumption

- 162,84 kWhep/m2.an

- 162,84 kWhep/m2.an

Real final energy consumption

70,80 kWhef/m2.an

Systems

- Urban network

- Fan coil

- Urban network

- Fan coil

- Double flow heat exchanger

- No renewable energy systems

Risks

- Urban heat island

Urban environment

- buses: 22, 28, 32, 80, 84, 93

- metro: 9, 13

- bike

- scooter

- cityscoot

- car sharing

- etc

- 100,00 %

Product

ARP Astrance

Julie VINAY

https://arp-astrance.com/Management / Others

Circular interior designer

KATABA

f.sedeno[a]kataba.fr

https://kataba.fr/Finishing work / Indoor facilities

MILLIKEN

sabrina.beauvois[a]milliken.com

https://www.milliken.com/fr-fr/businesses/floor-coveringFinishing work / flooring

Carpet / resilient flooring

BOUYGUES Energy

a.casule[a]bouygues-es.com

https://www.bouygues-es.fr/General contractor 2nd work

CultureIn

emma.derbre[a]culturein.eu

https://varian.culturein.eu/Varian acoustics

Algo

jacquy.binnet[a]algopaint.com

https://www.peinture-algo.fr/?gclid=EAIaIQobChMI6tn0uN7O_QIVzhAGAB06PgAlEAAYASAAEgLbE_D_BwEFinishing work / paints, mural, wallcoverings

Biobased paint. Recycled and recyclable container.

Construction and exploitation costs

- 60 000 €

- 280 000 €

Circular economy strategy

- Maximization of the number of impacted batches

- Maximization of quantities on targeted products

- Maximization of the carbon gain

- Maximization of the mass of waste avoided

Reuse : same function or different function

- Locksmithing-Metalwork

- Indoor joineries

- Floorings

- Partitions

- Suspended ceilings

- Raised floors

- Electricity

- Heating ventilation air conditioning

- Plumbing

- Reception desk: 1 U

- Lamp - Led strip: 2 U

- Metal cabinet: 6 U

- Office: 19 U

- Bookcase / wooden shelf: 1 U

- Chairs: 136 U

- Worktop: 1 U

- Coffee tables: 4 U

- Stools: 40 U

- Removable partition - glazed door block: 2 lm

- Removable partition - full filling: 24 ml

- Removable partition - glazed: 12 ml

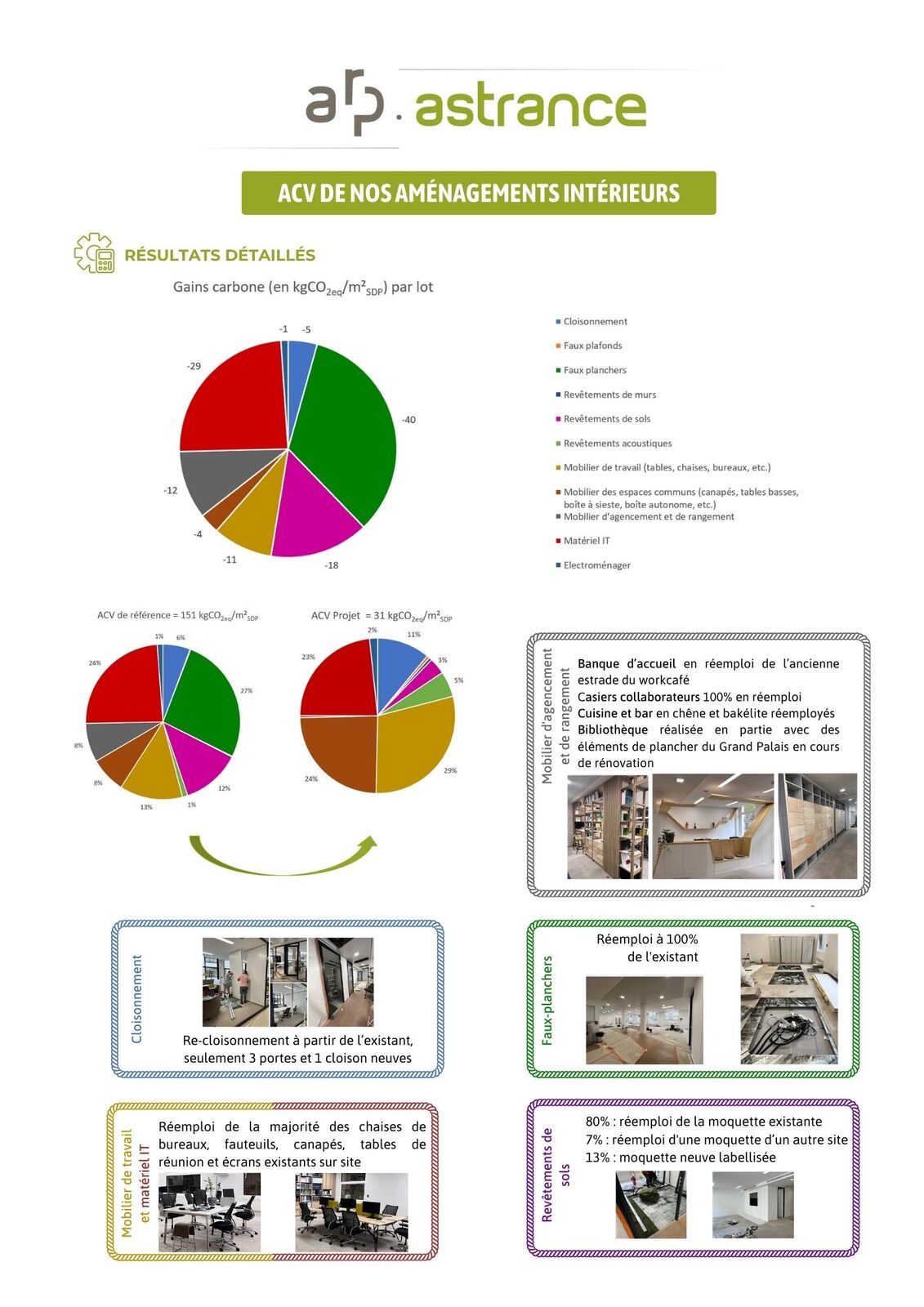

- Carpet: 21m²

- Office (locker, non-existent category): 125 U

- 65% of furniture in situ (mainly tables and seats) reused

- For non-reused furniture: 15% recovered by employees, 15% given to firefighters, 5% sent to a recycling/reuse channel

- Retention of 80% of the existing carpet

- Reuse of a carpet removed from another site (ORAK Partner)

- The new carpet is made from recycled nylon; it is Declare labeled and has low VOC emissions (MILLIKEN Partner)

- Reception desk: pine ribbon designed with the wood of the old platform

- Employee lockers: reuse of the old library, change of doors only

- Kitchen and bar: oak and bakelite + “LE PAVE” worktop (made from plastic waste)

- Library / Material library: only the white tops are new, the rest is reused, door made with floor elements from the Grand Palais

- Acoustic elements made of natural fibers and biosourced materials (Partners: CultureIn and PierrePlume)

- Colored paint: 84% biosourced (ALGO partner), packaging 75% recycled and 100% recyclable

- Traverse: old parquet

- Cleat: old beam

- Chipboard: old desk top

- 2.8 m3 chipboard --> 100% reuse

- Chipboard: old desk top

- 0.2 m3 plywood (door) --> 0% reuse

- 0.2 m3 chipboard + solid undersheet (door) --> 100% reuse

- 0.2 m3 chipboard --> 0% reuse

- 0.1m3 black compact strat panel --> 100% reuse

- 0.2 m3 solid wood --> 70% reuse

- 0.4 m3 medium --> 0% reuse

- 0.7 m3 chipboard --> 20% reuse

- 0.15 m3 3ply spruce --> 50% reuse

- Solid wood: 2.5 m3 including 2 m3 reused (i.e. 80%)

- Agglomerated: 5.95 m3 --> including 4.28 m3 reused (i.e. 70%)

- Plywood: 0.2 m3 --> new

- Compact laminate: 0.1 m3 --> 100% reuse

- Medium: 0.4 m3 --> new

- 3 ply spruce: 0.15 m3 --> of which 0.7 m3 is reused (i.e. 50%)

- Origin: carpet reused from BNP offices for the management office and green curtain space. It was provided to us by Milliken who works with ORAK to recondition the carpets.

- Mode of transformation: no transformation, carpet reused, but reconditioning with the partner ORAK.

- Installation: identical to new carpet, installation carried out by Bouygues.

- Difference compared to a classic material: no difference, identical use, but the LCA is improved as well as the carbon footprint.

- Critical analysis: easily achievable for small surfaces, very high environmental gain, but if we had to deploy the reused carpet on larger volumes, question of supply depending on the deposits available to have a unit on the whole.

- Provenance: parquet floor of the Grand Palais for the library, doors for the fronts of the lockers, up cycling of our former platform.

- Cooked worktop - recycled materials: paver made from agglomerated plastic particles

- Mode of transformation: carpentry - work in the workshop and assembly on site.

- Installation: Kataba via their partner who employs people in integration - workshop 1920.

- Difference from classic material: search for deposit, final rendering according to the deposit found.

- Analysis: difficulty of working on large volumes with a company that is not used to it, sector in structuring, takes a lot of time to search for the deposit and support for design and production, but gratifying to have furniture arranged in up cycling because the carbon footprint is greatly improved, no extraction of raw materials, participation in the ESS (social and solidarity economy).

- Installation: logistics on site to disassemble, store on site then reassemble in the right place

- Analysis: very advantageous in terms of cost and carbon footprint, no transport, no extraction of raw materials.

Logistics

- On site, on a dedicated area in a covered location

- On site, on a dedicated area in a covered location

Insurance

Environmental assessment

- 65% of furniture preserved

- 95% of partitioning re-used in situ

- 80% of carpet preserved

- 95% of technical equipment retained / overhauled

- 84% biobased paint

- Biosourced acoustics and reuse

- Reuse reception desk from the former "workcafé" platform.

- Employee lockers reused from the old library, only the doors changed.

- Kitchen and bar: reused oak and bakelite + “LE PAVÉ” worktop (made from plastic waste).

- Library / Material library: mostly reused, door made with floor elements from the Grand Palais.

- Reuse of the existing for shelves, cabinets, coat racks, etc.

- 80%: reuse of existing carpet.

- 7%: reuse of carpet from another site (16 m²).

- 13%: brand new carpet, with low VOC emissions and low carbon impact.

- 40%: Reuse of the existing false floor

- 60%: Out of scope because kept in the reference scenario

- Reuse of the majority of office chairs, existing workstations and meeting tables.

- Some new chairs and tables.

- Tertiary optimization: we can have a circularity of materials and fittings, but the first resource on which we must ask questions is that of the use of m², the optimization of uses, reversibility.

- The circular layout is also part of responding to the fair use of m² and ways of doing things. The reversibility of the developments is anticipated from the design stage.

- Thinking about the use of the m² goes hand in hand with responsible development.

- Following the observation of the climate emergency, it seems essential to us to engage in a paradigm shift and to bring a new vision for the design of interior design projects.

- Interior fittings have a significant impact on a building's carbon footprint.

- At ARP Astrance, we are committed to the protection of living things, with the Gondwana division which works in its own right on biodiversity issues.

- Making circular arrangements also means getting closer to the company's CSR challenges, giving meaning for employees, and a value of commitment.

- The circular economy is driven by SSE actors (reconditioning platforms, carpentry, materials handling, etc.), and generates job creation at the local level. The whole economy is being challenged by a new way of approaching the project and construction. Today, large companies must also take up the subject to structure the sector, this is the case of Bouygues Energies & Services who have done everything possible for the success of our project.

- Do with existing buildings. The future of real estate will develop in the rehabilitation and transformation of use of assets.

- Making circular layouts means optimizing existing resources, but it also means preparing for the redevelopments of the next few years by thinking about the reversibility of the project and the dismantling of the materials.

- Reused materials : floor and wall coverings, partitions, doors, raised floors

- Integration of healthy, biosourced or geosourced materials

- Materials easily separable for recycling or removable for reuse -> Ex Milliken with its Traction Back 2.0 carpet (tack-free installation)

- Cradle to Cradle label

- Reused or second-hand furniture (Bluedigo, Tricycle, etc.): chairs, desks, sofas, tables

- Definition of the scope, objectives and lifespan of the project

- Realization of the list of materials, products and equipment

- Search for emission factors

- Identification of the most emitting stations and proposal of variants

- Rule for taking reuse into account

- Comparison to the reference scenario and valuation

- Valuation as part of the company's scope 3 carbon footprint for the current year

- Reduction axis by the ACT method

- Respond to public procurement obligations on reuse

- Promote environmental commitment and a sense of belonging among employees

- Make its premises or projects a showcase of its commitment

- Valuation within the framework of a certification or a label (Zero Carbon Certification, the BBCA Exploitation label, the Circolab label)

- External communication on the % reduction in the carbon footprint of the interior design operation

- Extra-financial report and external communication

| reception desk | Furniture | |

| Lighting - Led strip / light throat | Lightings | 2 |

| Metal cabinet | Furniture | 6 |

| Desk | Furniture | 19 |

| Bookcase / wooden shelf | Furniture | 1 |

| Chairs | Furniture | 136 |

| Workplan | Furniture | 1 |

| Coffee tables | Furniture | 4 |

| Stools | Furniture | |

| Removable partition - glazed door block | Partitions | 2 |

| Removable partition - full filling | Partitions | 24 |

| Removable partition - glazed | Partitions | 12 |

| Carpet | floor coverings | 21 |

| Desk | Furniture | 125 |

How do we act?

Upstream phase of the project – framing, programming:

Environmental issues :

Operational phase of the project: design, drafting DCE, AO

Materials ; sourcing of reuse materials – working with reuse platforms.

Societal issues:

Economic issues :

Today, the sector is in the process of being structured, and there are already financial advantages to working in a circular development approach: selective cleaning for resale of materials to reuse platforms (Tricycle) VS the cost of a classic demolition, In situ reuse which is both virtuous for the carbon footprint and the financial balance sheet.

=> The design is not however set aside in a circular layout, on the contrary, it will allow the project to be supported – how to create beauty and with meaning.

We are working on an internal material library that makes sense and that we are developing according to criteria that we have defined (origin of materials, % of recycled materials, dismantling, reflection on the treatment of end-of-life materials, etc.)

Methodology implemented by ARP Astrance

This voluntary approach is enhanced by:

Economic assessment

- 200 000 €

- Purchase by the contracting authority from a reuse platform

- Purchase by the company from a reuse platform

Communication

Social economy

- Kataba

- Tricycle

Circular design

- Choice to reorganize our spaces rather than move.

- Use of in situ resources

- Maximization of construction waste: use of what we had at home.

- Biosourced materials: paint, acoustics.

Comfort

- Addition of wall and suspended acoustic panels in meeting spaces;

- Carpet with acoustic underlay;

- Enveloping office furniture with acoustic material.

- Eye-soothing biophilic design and reminder of nature: disconnect;

- The finish of the new desk tops has been chosen to limit reflection.

Quality of life and services

Desire to strengthen the quality of life at work through workspaces: social ties, biophilia, sanitary quality of spaces

This resulted in the presence of biophilic elements:

- A natural green wall

- Natural materials present on the entire board: cork, wood

- Naturally inspired lights

- The color palette of the wall coverings has been selected to recall natural materials or presents patterns of natural inspiration (wallpaper, window sticker, cork panel)

- “Refuge” alcoves in the silence space

- In addition, the plateau that we occupy has important qualities in terms of natural light thanks to large glazed surfaces and a double exposure in a large part of the spaces.

General infos

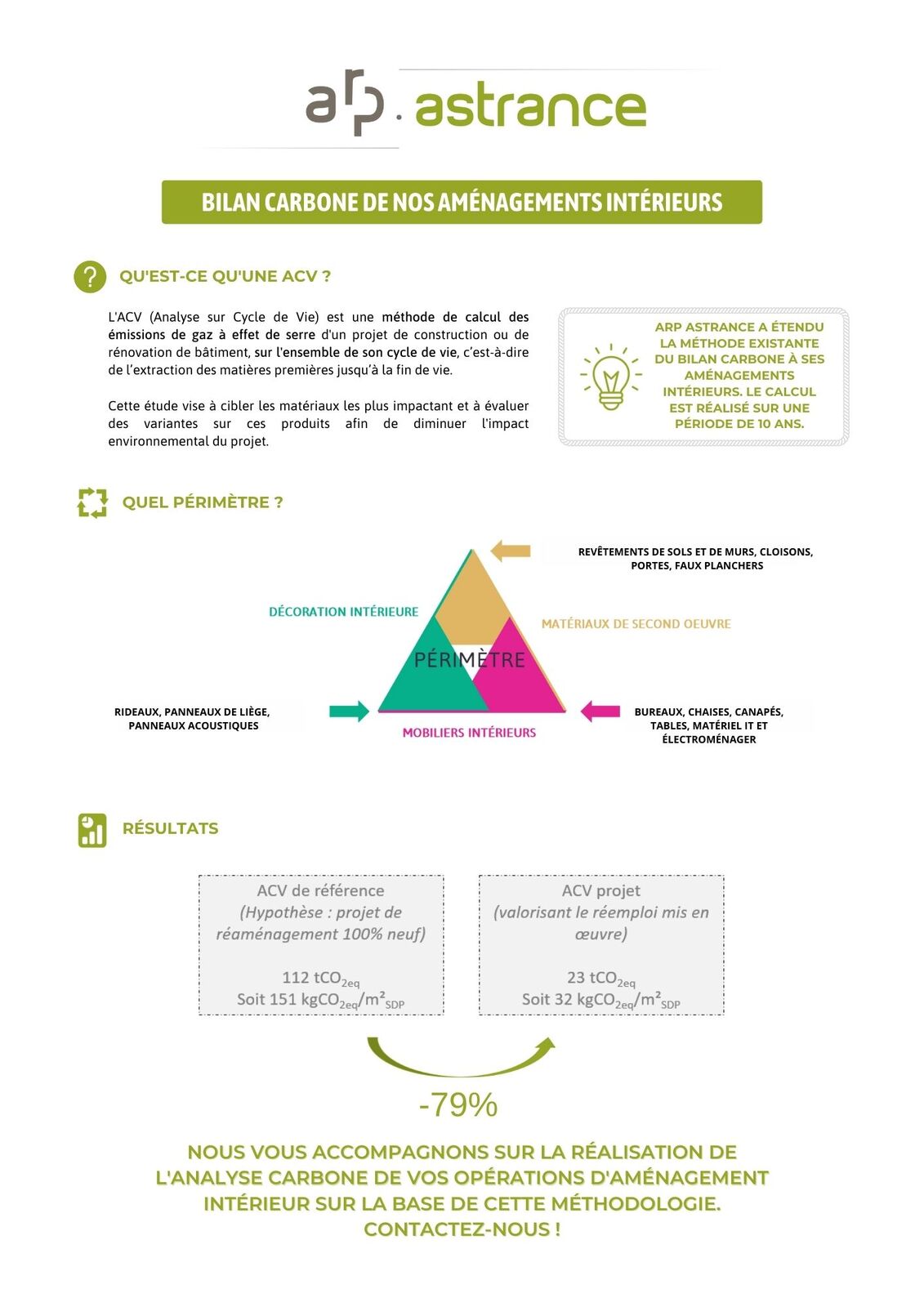

ARP Astrance has developed a specific carbon footprint methodology for interior fittings operations (scope of intervention currently very little covered by existing tools and methods on the market).

GHG emissions

- 31,00 KgCO2/m2/an

Life Cycle Analysis

- Definition of the scope, objectives and lifespan of the project

- Realization of the list of materials, products and equipment

- Search for emission factors

- Identification of the most emitting stations and proposal of variants

- Rule for taking reuse into account

- Comparison to the reference scenario and valuation

- Valuation as part of the company's scope 3 carbon footprint for the current year

- Reduction axis by the ACT method

- Respond to public procurement obligations on reuse

- Promote environmental commitment and a sense of belonging among employees

- Make its premises or projects a showcase of its commitment

- Valuation within the framework of a certification or a label (Zero Carbon Certification, the BBCA Exploitation label, the Circolab label)

- External communication on the % reduction in the carbon footprint of the interior design operation

- Extra-financial report and external communication

Reasons for participating in the competition(s)

Nous souhaitons que ce projet démontre la faisabilité technique et économique d’aménagement intérieur à faible impact environnemental et à haut taux de réemploi, tout en maintenant les objectifs esthétiques et de qualité de vie.

L'obtention d’un Trophée permettrait d’ajouter du poids à nos communications sur le projet pour engager le plus grand nombre.

Nos actions en synthèse :

- La mise en œuvre de solutions économes en ressources et développées par des sociétés partageant nos valeurs et issues pour certaines de l’ESS

- Un réemploi maximum de tous les éléments de 2nd oeuvre et des agencements présents avant le réaménagement.

- Un objectif fort d'un bilan carbone le plus faible possible pour l'opération, validé à la livraison.

- Le choix de solutions favorables à la santé et au bien-être des collaborateurs : design biophilique, choix des matériaux à faibles émissions, couleurs, postures variées, etc.

- Une démarche collaborative pour répondre aux réels besoins des utilisateurs et pour faciliter la prise en main des nouveaux espaces.

- La conception d’un écosystème d’espaces propices à la transversalité et la collaboration et permettant une optimisation des surfaces.

Notre projet est une réponse aux modes de travail hybride et aux défis environnementaux, et besoin d’allier espaces et valeurs de l’entreprise : nos nouveaux espaces de travail proposent des espaces inspirants car guidés par le vivant, respectueux de chacun, et à faible empreinte carbone.

Projet possible par l’implication de tous : direction, collaborateurs, partenaires. Une double réussite : la réduction de l’impact négatif du projet et des impacts positifs pour nous et notre éco-système.