A DHW recirculation system that does not waste any energy at all

Problem:

Domestic hot water can represent up to 40% of energy consumption in a residential building, home or apartment and 30% to 50% of the heat produced during the generation of collective hot water disappear into the distribution loop.

The "demand controls" looks to be the one that waste the less energy but it still have two main disadvantages:

1) The waiting time for hot water is too long. To evacuate 6 L of cold water it lasts +/-30 secs when the cold water is evacuated in the sink. With the "on demand" solution it takes more than 3 min because the centrifugal pump generates only a small difference of pressure, the hot water advances to about 2 L / min.

When they are alone, users use the fastest way.

2) Even when it is wisely used, the "demand control" still wastes 2 KWh / day of energy because it sends the hot water throughout the house while the demand is only for one tap.

Measure yourself the energy wasted.

Install a thermal energy counter (some can be simply clamped) on the pipe that return the water to the water heater and connect the two temperature gauges to both ends of the loop.

Measure also the circulation pump electrical consumption.

Solution:

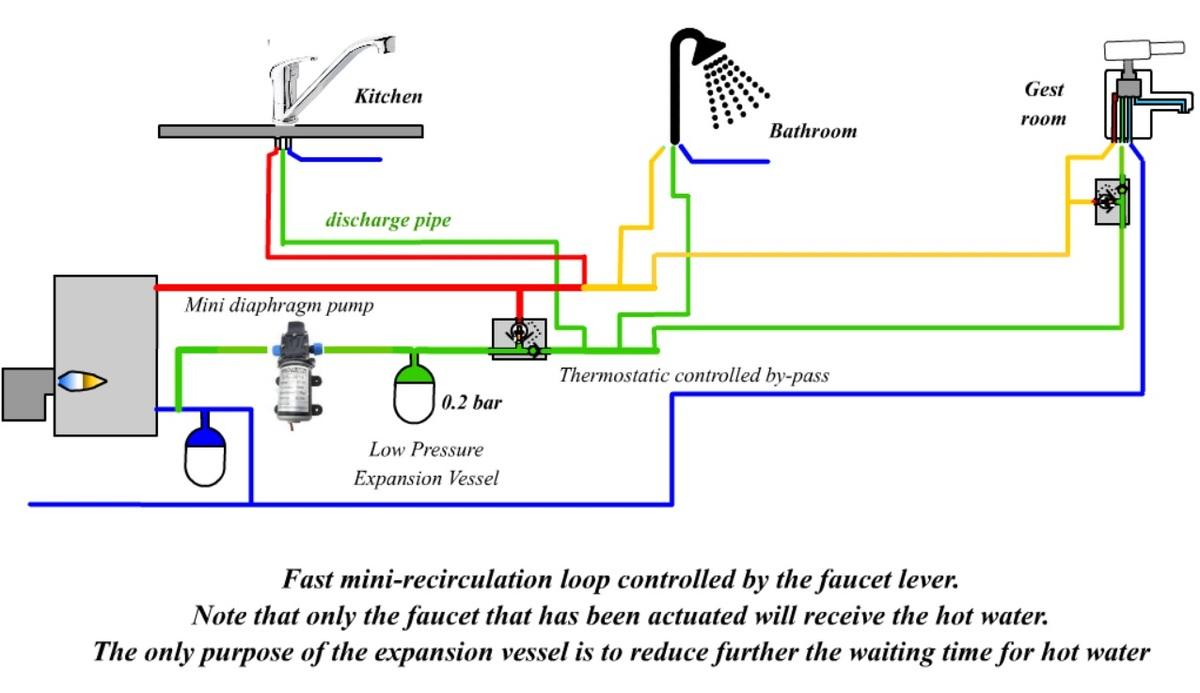

A fast mini-recirculation loop controlled by the lever of the water-saving faucet

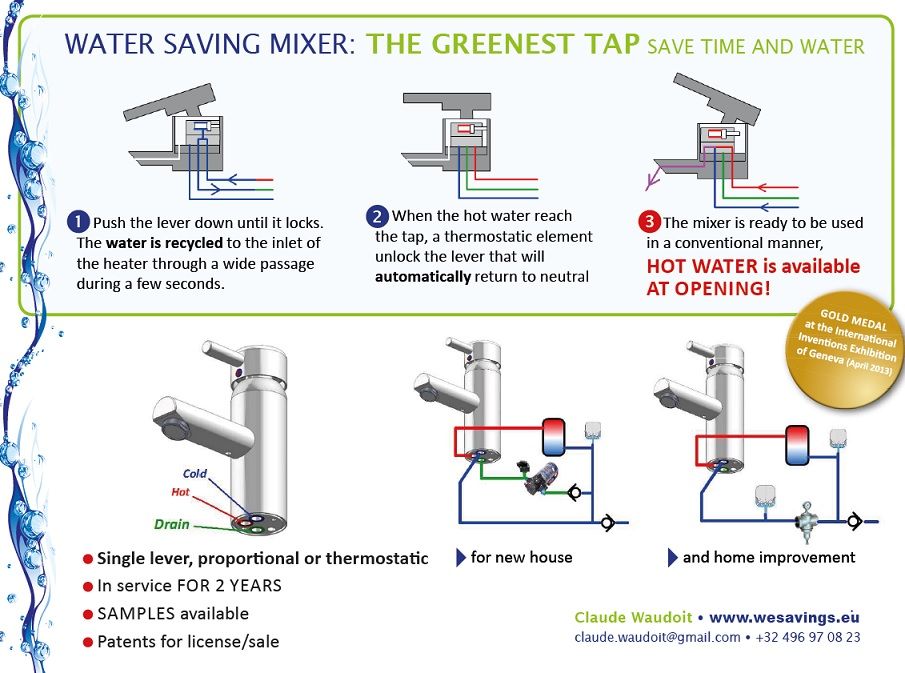

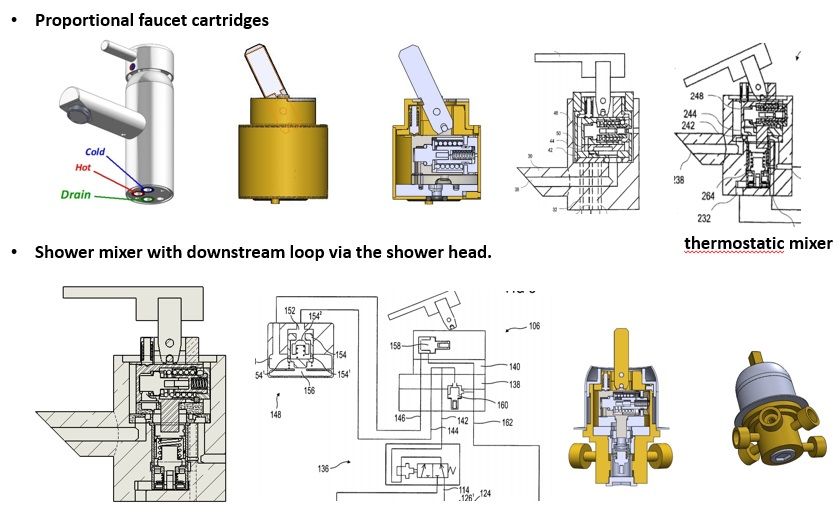

The water-saving faucet has the same look and the same functions as a conventional water mixer, but it has an additional drain orifice and an internal by-pass controlled by the lever position

1) You push the lever down until it locks: the water contained in the hot water pipes, at the pressure of the water network, is quickly directed to a low pressure expansion tank, via the drain orifice of the faucet.

2) Within seconds the hot water reach the tap and a mini thermostatic element unlocks the lever that will automatically return to neutral, thus indicating that the hot water is available at the faucet.

3) The cold water that was originally present in the hot water pipes and that has been sent to the low pressure expansion tank will automatically be sent to the water heater inlet via a small automatic diaphragm pump (a pump that is often used in the motor-homes).

The fast mini recirculation loop controlled by the water-saving faucet do not waste any water and do not waste any energy at all.

The faucet is modified to add a drain port and a mini thermostat in the cartridge. The faucet is a bit more expensive, but in production the additional cost should be less than 5 USD (in most current taps, the cartridge with ceramic discs costs less than 1 USD).

To return the water to the water heater, the piping that was previously used for looping can be used.

The centrifugal pump is replaced by a small diaphragm pump which works automatically as it is controlled by an anti-cavitation switch. The pump is cheap but has only a flow rate of 5 L / min, so a very low pressure expansion tank is added to reduce the waiting time for hot water.

To further reduce the waiting time for hot water, one or several thermostatic bypasses controlled by the flow in the return pipe can be added. The water contained in the trunk line is evacuated in priority via a return line which has the same diameter.

For the shower application, the thermostatic water-saving mixer tap will control a loopback circuitry via the shower head, so you can enter the shower before opening the tap with no risk to receive a single drop of cold water, without any water and energy wasting for more comfort and a strict minimum water consumption: https://www.youtube.com/watch?v=l3iTB2x38Qs

Seeks for a partner for the manufacturing and marketing of the products, or an intermediary to help monetize the patents in order to invest in the development of a freewheeling hydraulic transmission.

More info: www.wesavings.eu