Reconversion of the Seveso wasteland of La Barillais into an Ecopark

Last modified by the author on 16/03/2023 - 18:32

- Address 1 - street : La Barillais 44550 MONTOIR-DE-BRETAGNE, France

- Diameter : 2300

- Green energies : Energy production, Hydrogen, Photovoltaic solar, Biogas, Biofuel, Gas, Other

- Circular economy and waste management : Production, Waste Recycling, Methanation, Methanation unit

- Biodiversity & Ecosystems : / Ecoystem restauration, Ground recovery, Carbon capture /

-

10 000 000 €

This project won the Sustainable Infrastructure Grand Prize at the Green Solutions Awards France 2022-2023 in a tie with the Oasis courtyard at the Maryse Hilsz school.

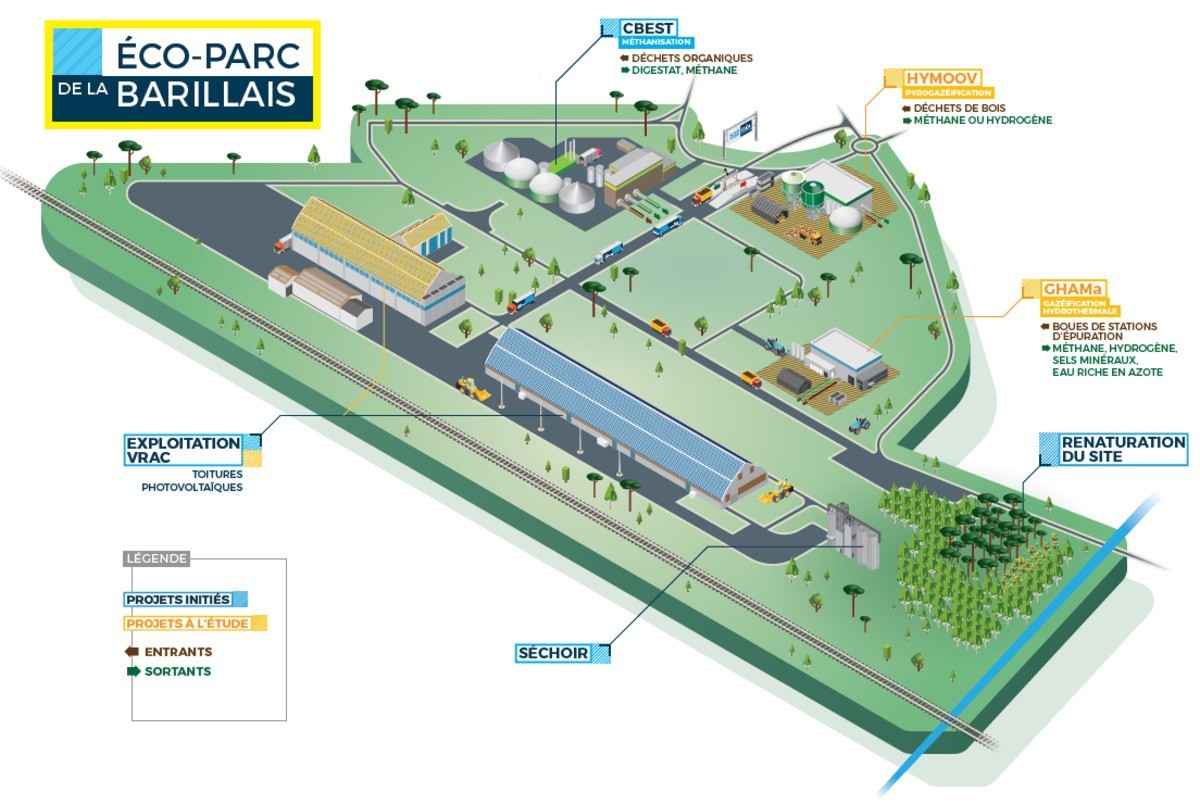

Since 2009, IDEA, a company specializing in logistics and bulk transport, has initiated a large-scale project: gradually buying back the 19-hectare site of the La Barillais wasteland in Montoir-de-Bretagne, near Saint-Nazaire (Loire-Atlantique) and transform it into a virtuous site. It is from this approach that the La Barillais ecopark was born, on which the storage and drying of cereals and oilseeds rub shoulders with various experimental and environmental activities.

The issues addressed are multiple:

- Respecting the ZAN law (zero net artificialisation) and fight against the artificialization of soils. As an industrial logistics company, IDEA needs large expanses to develop its activities. Choosing to rehabilitate already artificialized and polluted areas is part of this strategy.

- Promoting the production of low-carbon energies. The ecopark is a place for experimenting with new technologies to produce renewable energies. These demonstrators make it possible to validate the technical and financial viability of these innovations to allow the transition to an industrial scale.

- Reducing the impact of its road activities thanks to the biogas produced on site.

- Creating an educational place for the general public and local players, with, for example, school visits.

Clean up and renature a dangerous site

The La Barillais wasteland was an installation classified for the Seveso upper threshold environment. It housed a chemical fertilizer storage site presenting a risk of major accidents. A high level of prevention was therefore maintained there. The previous owner undertook the depollution of the soil. After stopping the fertilizer storage activities, a comparative study of soil pollution between the initial state - takeover of the wasteland by IDEA - and the final state - stopping the fertilizer storage - was carried out, demonstrating that there was no additional pollution in the groundwater.

The 19 hectares of the ecopark have also made it possible to reintroduce plants on this industrial site. In partnership with Neosylva, unused land has been used to develop wooded or renatured areas and reclaim certain abandoned areas in order to see flora and fauna reborn. A total of 1,000 maritime pines, birches and holm oaks were planted at the start of 2022. These spaces also store atmospheric carbon produced by the site's activities.

An experimentation hub for low-carbon energies

Photovoltaic power plant

Since 2011, IDEA has taken advantage of the roof of a large hangar that dates from the industrial past of the wasteland for the installation of a photovoltaic power plant. 5,000 m² of solar panels are installed for a production of up to 4.5 MWh per day in summer.

IDEA will commission a new solar lot, on this site and on others in the region, this time as an investor.

Methanisation unit

At the heart of IDEA's energy transition strategy is the desire to recover local waste to produce energy. The transformation of this waste, close to its deposits, makes it possible to offer a local treatment solution for industrialists, communities and farmers, and to turn it into an energy resource produced in a short circuit.

Anaerobic digestion then appeared as a first lever to be activated. The proximity of the La Barillais wasteland to the expressway, the port and gas lines makes it a prime site. The initiative was launched in 2018, and in 2022 two huge concrete tanks on 1.3 hectares were born. The Biogas Plant of the Estuary (CBEST) uses waste from 12 farms and several agro-food industries: manure, slurry, agro-industrial sludge, grease and grain dust. Each year, 25,000 tons of waste are treated in this way.

The plant produces 2.3 million m 3 of biomethane per year, equivalent to the annual consumption of 1,900 households. The biogas produced, which conforms to the quality of natural gas, is injected directly into the network operated by GRDF to directly supply consumers in Montoir-de-Bretagne, Trignac, Donges, Saint-Joachim and Saint-Malo-de -Guersac.

The methanization process also allows the production of a digestate, an organic amendment that can be spread on neighboring crops. This amendment thus replaces the chemical products of the farms which supply their waste. The circle is complete: manufacturers are offered a sector to treat their waste and produce added value, and they recover a material to use on their crops!

Finally, it is planned in the coming years to recover and liquefy the CO2 resulting from the methanization process to offer it to market gardeners and industrialists.

Hydrogen production

In 2021, IDEA established a partnership with the Nantes-based company Iremia, which has been involved for several years in the field of wood storage and treatment activities. From this alliance was born Hymoov: a startup that takes advantage of the complementary expertise of its two founders to diversify the ways of recovering this wood waste and producing renewable energies. Using a pyrogasification process, the company aims to convert dry biomass waste into two virtuous energy carriers, biomethane and biohydrogen, by 2025.

Hydrothermal gasification

Still with a view to recovering local waste, the wasteland will host GHAMa by 2024, a hydrothermal gasification unit that will treat sludge from wastewater treatment plants. Hydrothermal gasification is a type of pyrogasification, the sector of which is less developed. The structure in La Barillais will aim in particular to support, accompany and structure this technology by using sewage sludge from CARENE (Saint-Nazaire Agglomeration) to create renewable gas.

Decarbonization of the vehicle fleet

In order to reduce its carbon footprint, IDEA commissioned its first six biogas tractors in May 2022 and will receive six more in 2023. These are the first results of an investment of 10 million euros which is part of the company's objective to decarbonize 40% of its fleet by 2025.

Progress Status

In progress

Data Reliability

Self-declared

Funding Type

Public/Private Partnership

Website Enterprise / Infrastructure

https://www.groupe-idea.com/frhttps://hymoov.com/

https://www.neosylva.fr/

Sustainable Development

Governance

IDEA

Private Company

The ecopark belongs to IDEA, which partners with various actors to develop the different activities.

For CBEST, Engie Bioz carries out the technical study of the process, operator of the methanisation unit and investor; IDEA is a territorial facilitator, site entry/exit operator with pooling of the entire park and investor; and CARENE is an investor.

Hymoov is supported equally by IDEA and Iremia.

GHAMa is supported by a consortium made up of GRT Gaz, Leroux and Lotz, La Carène, Nevezus, an industrial specialist in waste and IDEA.

The methanisation unit, at a cost of 10 million euros, is financed by a public-private partnership between Engie Bioz (70%), Idea (25%) and CARENE (5%). Subsidies from the ERDF (European Regional Development Fund) of up to €500,000 have been obtained.

Sustainable Solutions

- Waste management

- Renewable energies

Anaerobic digestion

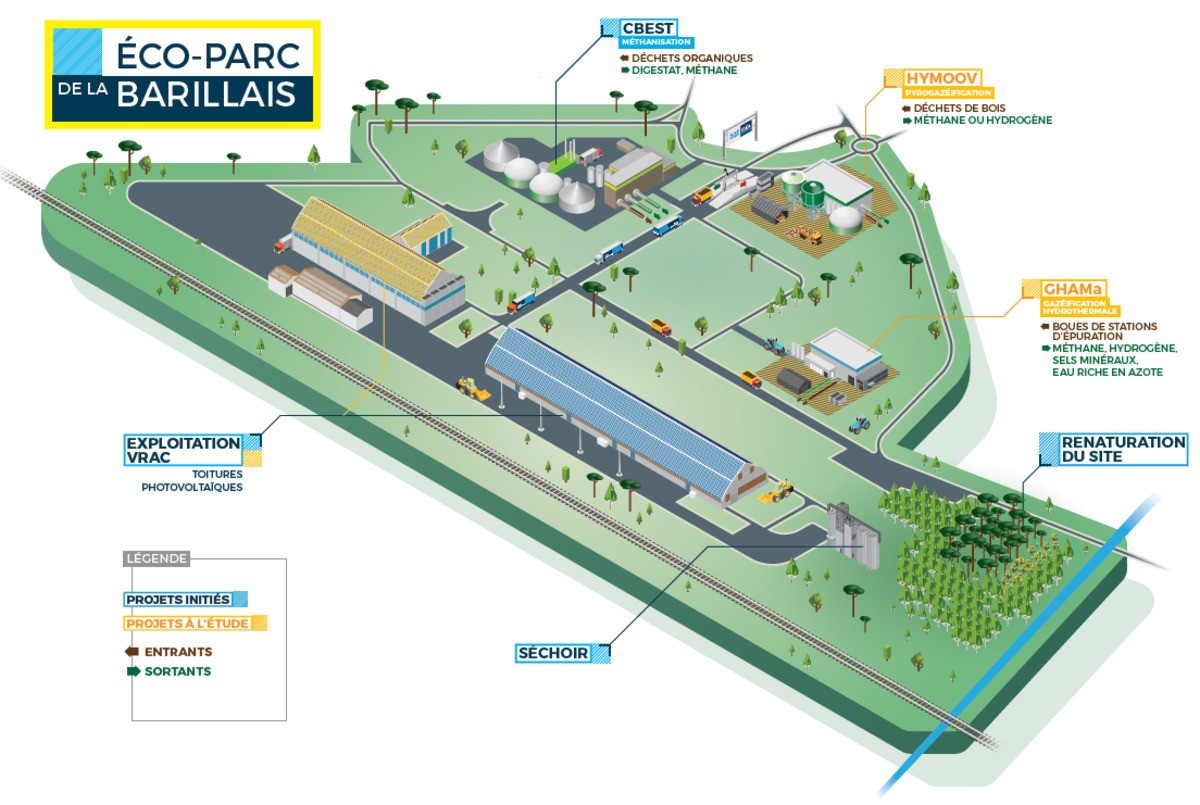

Anaerobic digestion makes it possible to create renewable gas from organic waste and co-products.

In vats called digesters, materials recovered from farmers, agri-food manufacturers, equestrian centers, etc. ferment. The material is then heated to 38°C, without oxygen, for fifty days. Bacteria degrade this organic matter and produce biogas.

The rations are analyzed by a biology service in order to adjust them every day and to incorporate a material that allows to obtain a good energy power.

The biogas produced, consisting of approximately 60% methane and 40% carbon dioxide, as well as 1% oxygen, nitrogen and water, is then purified in columns where a mineral support captures the methane. It is then separated from the CO2.

The biomethane, which conforms to the quality of natural gas, is then injected into the GRDF distribution network.

Source text and diagram: GRDF

- Waste management

- Renewable energies

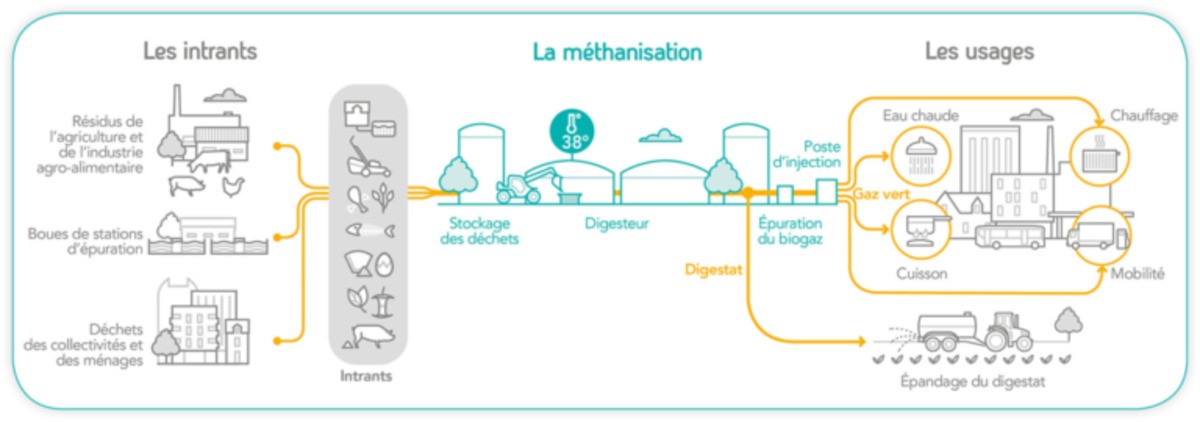

Pyrogasification

Pyrogasification makes it possible to recover biomass and various residual waste (dry agricultural by-products, dried sludge, residues from the wood industry not otherwise recovered, prepared sorting refusals - CSR, etc.) to produce heat and/or electricity or a syngas that can be injected into existing gas networks.

It is based on pyrolysis and gasification processes, which convert this dry matter at high temperature (500 to 1500°C) and in the absence of oxygen. The co-products are carbonaceous solids, oils and a gaseous mixture (syngas) composed of CO, CO2, H2 and CH4. The higher the process temperature, the more the material is converted into syngas, with the least possible solid or liquid effluents. This syngas can then be separated into refined gases that are more easily transportable and recoverable on site or remotely (synthetic methane, hydrogen and industrial CO2). Conversely, combustion and incineration immediately use the energy of the products or waste in the form of heat, by oxidation in the presence of oxygen.

After this transformation in a more easily recoverable form, these new compounds can thus be used directly downstream or on another site, either in energy form, for example in a boiler or an internal combustion engine as a substitute for fossil fuel or after injection into the gas network, either in chemical form for the preparation of biofuels or molecules with high added value.

Source text: ATEE

Schematic: Hymoov

- Waste management

- Renewable energies

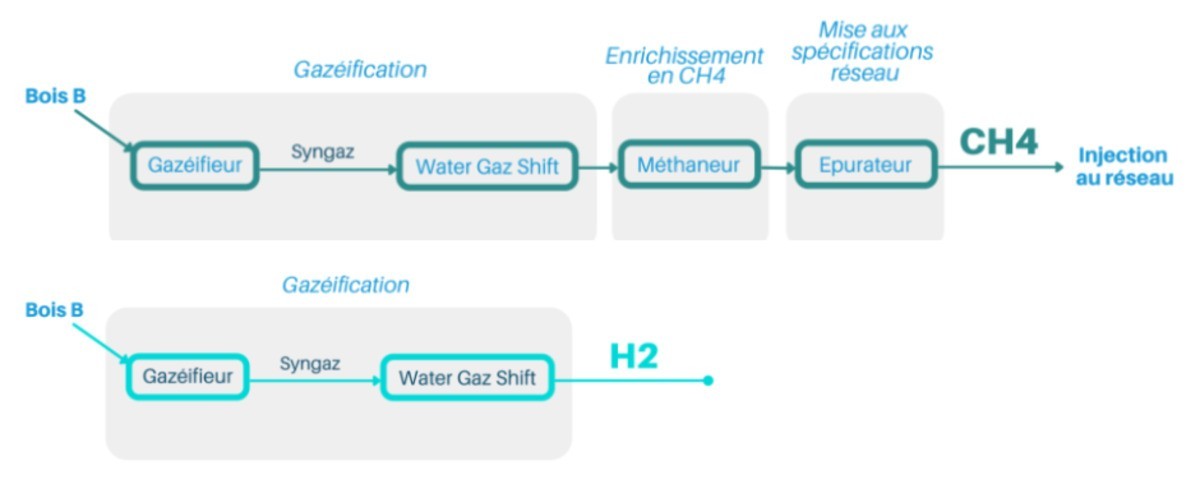

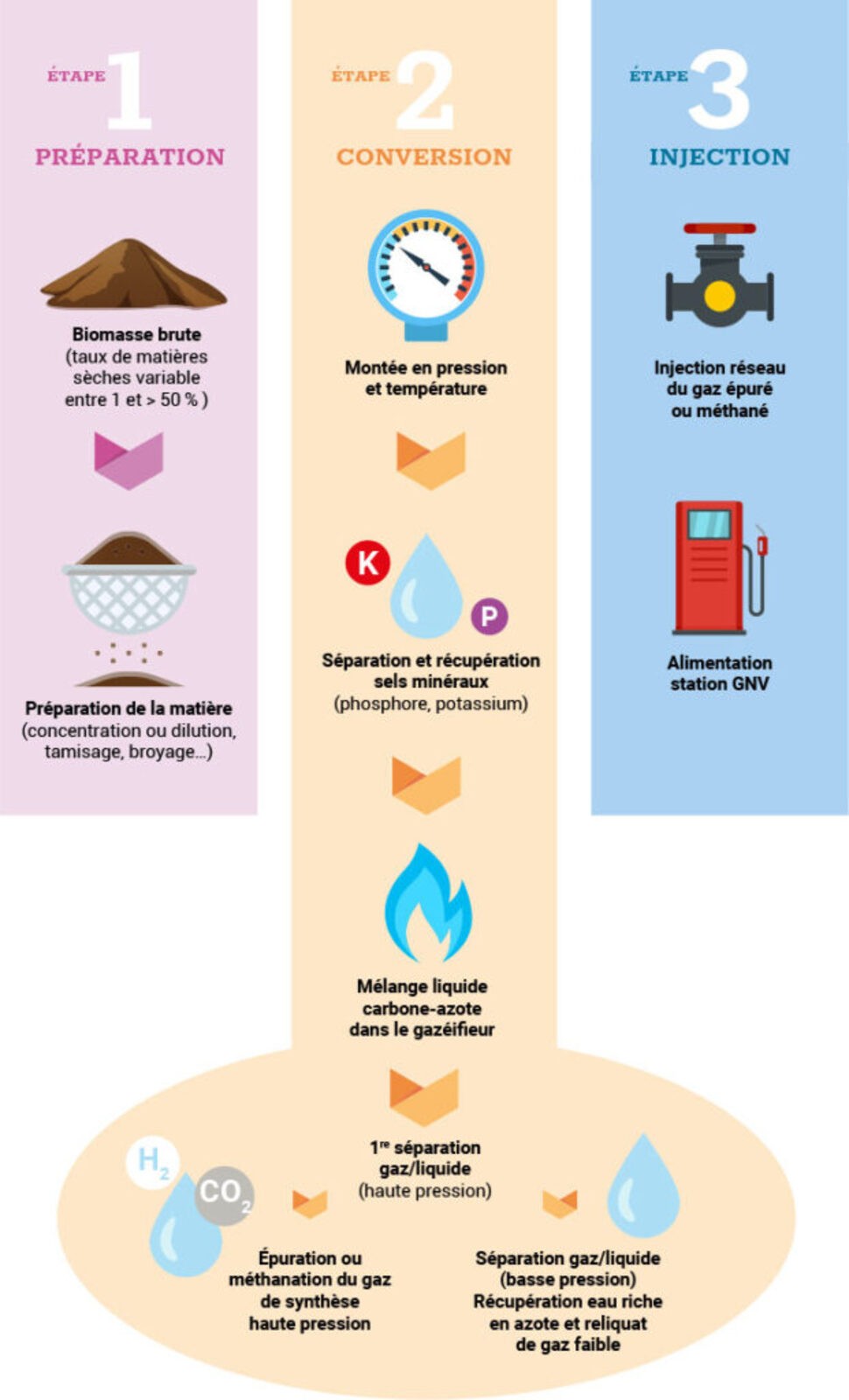

Hydrothermal gasification

This high pressure (210 to 300 bar) and high temperature (360 to 700°C) thermochemical process converts wet biomass into synthesis gas: a mixture composed mainly of CH4 (methane), H2 (hydrogen) and CO2 (carbon) .

Hydrothermal Gasification makes it possible to produce a synthetic gas rich in methane, hydrogen and carbon dioxide. Its composition varies according to the characteristics of the biomass treated, the process (with or without integrated catalysis) and the operational functioning (flow rate, residence time, presence or absence of a salt separator).

In Europe, several players are developing or operating Hydrothermal Gasification pilots or demonstrators.

Source text and diagram: GRTgaz

Photo credit

IDEA

Reasons for participating in the competition(s)

L'écoparc de La Barillais offre des solutions concrètes aux questions de traitement des déchets organiques et de production énergétique. Les diverses expérimentations soutiennent la structuration de filières qui ne sont pas encore viables. Les bienfaits sont multiples : création de circuits de valorisation des ressources en économie circulaire, création d'emplois locaux, développement d'entreprises et startups régionales qui profitent de la structure d'IDEA, production d'une énergie verte française, etc.