ITE in straw bales - Convention (15th)

Last modified by the author on 30/05/2022 - 09:57

Renovation

- Building Type : Collective housing < 50m

- Construction Year : 1930

- Delivery year : 2021

- Address 1 - street : 132 rue de la convention 75015 PARIS, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 1 000 m2

- Construction/refurbishment cost : 220 000 €

- Number of Dwelling : 14 Dwelling

- Cost/m2 : 220 €/m2

-

Primary energy need

15 kWhep/m2.an

(Calculation method : RT 2012 )

Save the resource

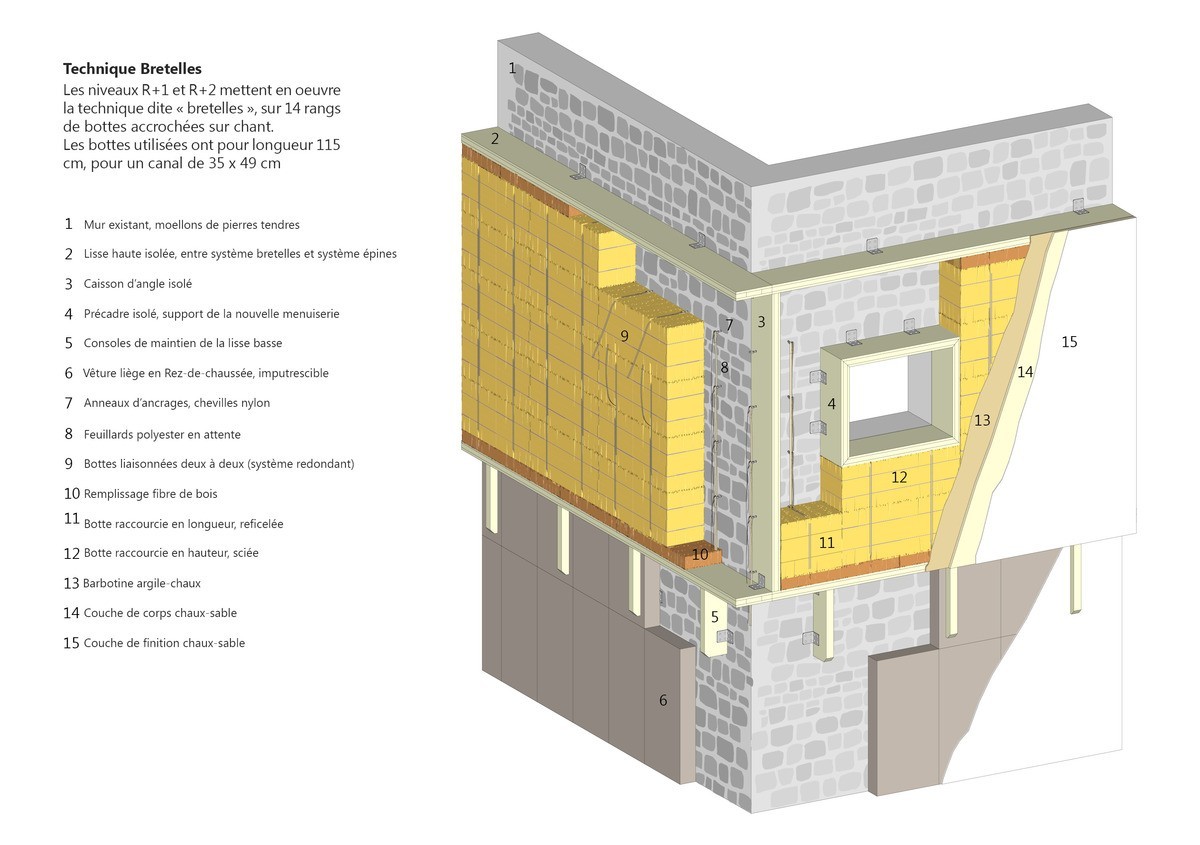

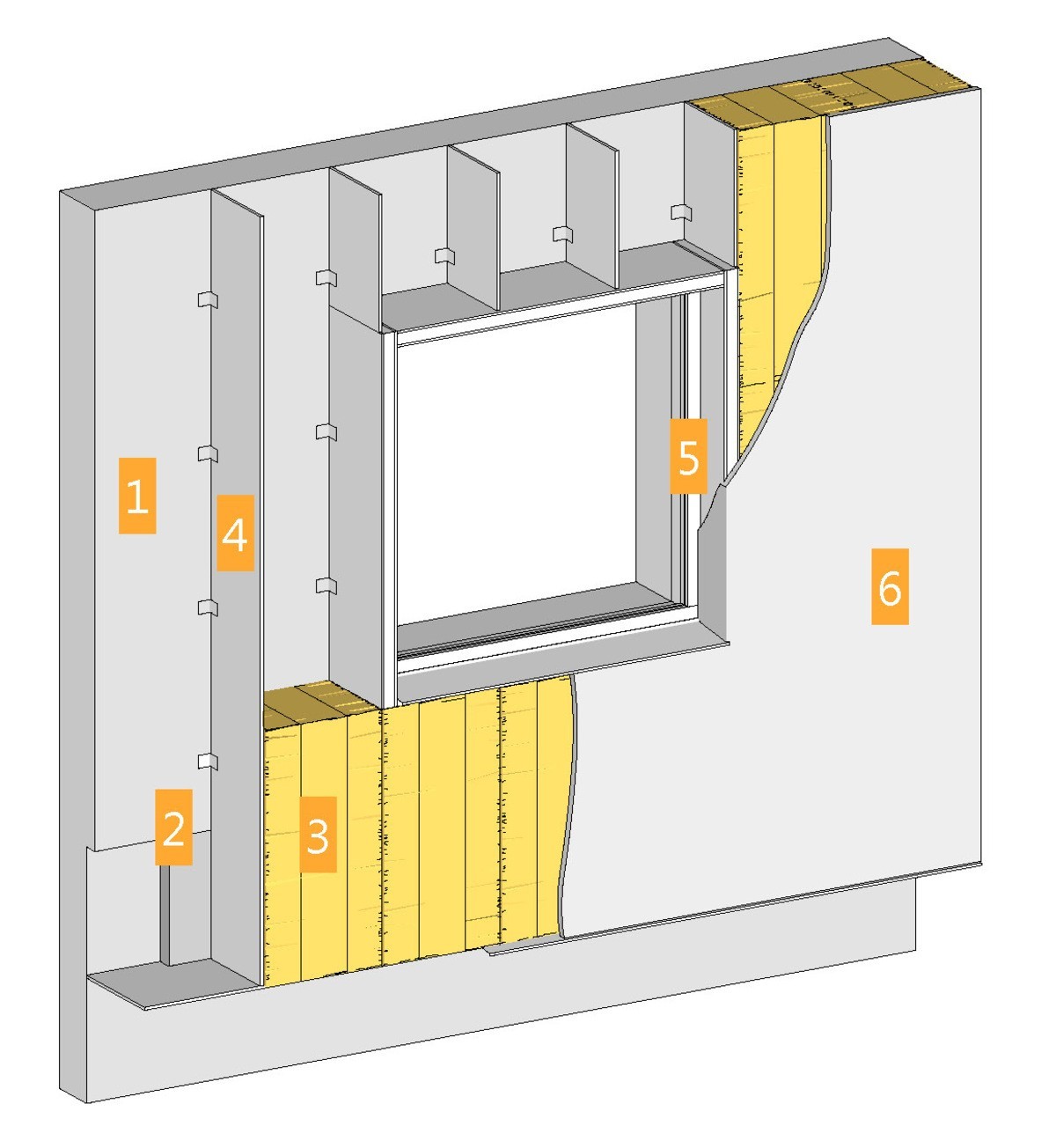

Most of the work falls within a conventional and regulated framework (R+3 to R+7). Plywood thorns 35cm wide fixed on the existing masonry are used to transfer the loads (straw + coating). This is a variant of the professional rules of straw construction with a wooden frame, where the straw is embedded between the thorns . The ramp area (R+1 and R+2) is more experimental because there is no wooden upright. The straw bales are directly fixed to the existing masonry by straps. The use of a stretcher-setter is a first on a straw construction site, even if the strap technique has already been used on many individual houses. The objective of this implementation is to save wood resources , where straw is abundant. And to demonstrate that we can train future professionals on a training site with public contracting authority. A reappropriation of the act of building is at stake for designers, craftsmen and users to create together the resilient cities of tomorrow.

Embodied energy comparison

The most spectacular advantage of the suspender system lies in the low incorporated embodied energy . Let's compare some systems with equivalent thermal resistance (7.2 Wm-1.K-1):

Conventional system, expanded polystyrene, single-layer synthetic coating: | 137.7kWh/m² |

Thorns, straw and plywood system, lime-sand render 3 cm: | 48.7kWh/m² |

Suspender system, straw and polyester strips, lime-sand coating 3 cm: | 27.8kWh/m² |

Optimized suspender system, clay body coatings and lighter hardware | 13.8kWh/m² |

Lime-sand body rendering constitutes an important part of the primary energy incorporated in rue de la Convention. A more homogeneous mixture than the fiber-reinforced earth coating, it is easier to project, in the case of large surfaces which call for a certain mechanization. In the case of a body plaster in raw earth and a simple lime-sand finish, the energy balance would be even better: ten times less than its polystyrene equivalent!

Availablity

Taken with a geographical distance, wood-soil-straw techniques are part of a virtuous territorial metabolism. Straw, as well as wood, stores carbon, around 14 kg of CO2 per square meter. The renewal of straw is annual and its availability immense, since 10% of the straw produced and not used by agricultural uses would be enough to insulate the new buildings built each year. On this principle, insulating existing buildings is also possible: puncture the excess straw ona duration of less than fifteen years would make it possible to isolate the entire building stock.

The technique

Conventional insulation products, whether in panels (polystyrene, wood fiber), or in rolls (mineral wool) are fixed without a framework using specific anchors: glue dots or plastic rosettes. Within the Collect'IF Paille and the architecture agencies Landfabrik and Trait Vivant, we wanted to continue research and experimentation on ITE by imagining a more economical system than current practices. It all started with a simple question: can the bales of straw be hung on an existing wall without using a framework? After discussions, sketches and telephone exchanges, the system of suspenders begins to be born. The boots are placed on edge, held in pairs by pairs of suspenders (in fact straps dedicated to the packaging industry). Four anchors per square meter ensure a continuous load distribution on the existing wall and reduce the stresses in each strap to less than 10% of its advertised strength.

The worksite-school

The exterior insulation of an 8-storey building at 132 rue de la Convention (Paris 15th) for the social landlord Paris Habitat was the occasion for a first project to test the installation by suspenders on the scale of a building – in participatory construction and on the first and second floor. The upper levels have been isolated by bales of straw placed between plywood panel spines by the Apijbat and Since 1920 companies. taken individually, the stones remain friable. We have chosen for the anchoring nylon dowels, which are not very aggressive for brittle stones, and scaffolding rings. This solution appears oversized: these rings withstand 1.6 T while the weight of the envelope relative to each anchor does not exceed 30 kg.

It is common to use strapping or webbing in straw construction to maintain the necessary compression in the boots, when they are structural. Manual crimpers and their associated consumables are then used, textile strips or woven polyester straps. For this project, we made the choice to invest in an industrial machine to tighten the straps. This choice brought us two advantages: the machine is adjustable and guarantees a constant level of compression on all the boots on the participatory worksite; the tightening of the strips and their welding become very fast operations.

Building users opinion

Very happy during the construction site: no nuisance, no noise (no machinery)

See more details about this project

https://www.apave.com/fr-FR/Actualites/News/Paris-Habitat-missionne-Apave-isolation-thermique-bottes-de-paillePhoto credit

Edward Vermes

Contractor

Construction Manager

Stakeholders

Designer

LANDFABRIK

Benoit Rougelot

https://landfabrik.fr/co-president of the RFCP

Thermal consultancy agency

Qui Plus Est

https://www.quiplusest.coop/Company

APIJ BAT

Rémy Beauvisage

Company

Depuis 1920

Nathan Levinson

https://depuis1920.fr/Company

Ravalement de Paris

Environmental consultancy

APAVE

Laurent Dandres

https://www.apave.fr/Control office

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 15,00 kWhep/m2.an

- 50,00 kWhep/m2.an

- 75,00 kWhep/m2.an

Systems

- Urban network

- Other hot water system

- No cooling system

- Natural ventilation

- No renewable energy systems

Risks

- Urban heat island

Urban environment

Product

Thermal insulation from the outside in straw bales / thorns and braces technique

agriculteur + artisan

collect'IF paille

http://rfcp.fr

Environmental assessment

Social economy

Reasons for participating in the competition(s)

Le rechauffement climatique est planètaire. Aujourd'hui, en Inde et Pakistan, hier en Australie et Canada, demain les canicules s'enchaîneront sur le territoire européen avec la même vigueur. Les métropoles très imperméabilisées comme Paris, souffriront des îlots de chaleur urbaine. Diminuer par une isolation thermique sans aggraver le bilan carbone en utilisant des matériaux biosourcés est une manière de baisser la température des façades. Utiliser des enduits à la chaux de couleur claire va dans le même sens (et permet par ailleurs la protection au feu de l'isolant, particulièrement pertinent en période caniculaire)

On peut donc agir à la fois sur les causes du changement climatique (l'impact carbone de la construction et utilisation d'energie fossiles pour chauffer les passoires thermiques) et ses conséquences (canicules).

Building candidate in the category