Compagnons du Devoir training center in Strasbourg

Last modified by the author on 01/03/2023 - 13:51

New Construction

- Building Type : School, college, university

- Construction Year : 2021

- Delivery year : 2023

- Address 1 - street : 2A route des Romains 67200 STRASBOURG, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

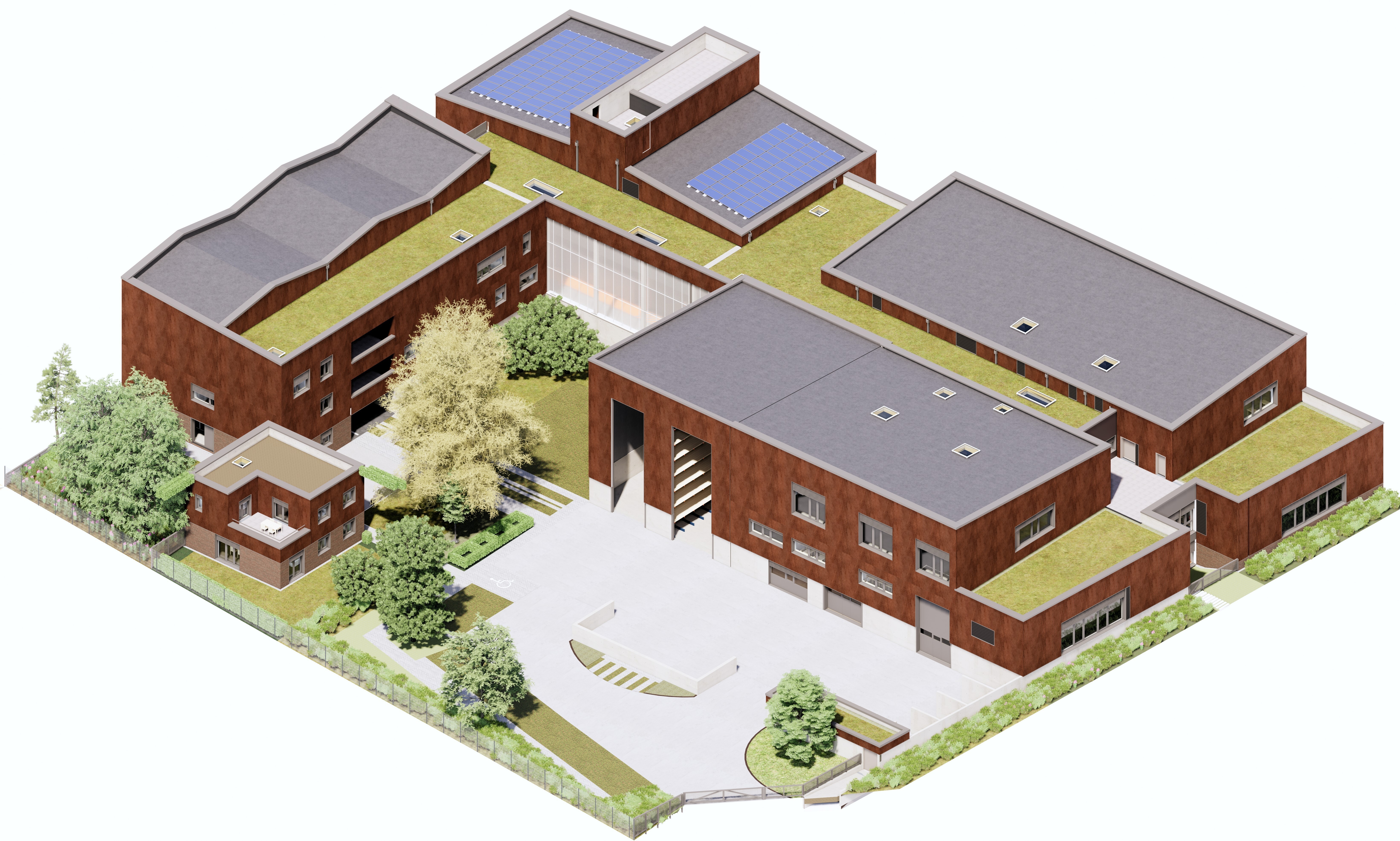

- Net Floor Area : 6 251 m2

- Construction/refurbishment cost : 11 483 000 €

- Number of Pupil : 425 Pupil

- Cost/m2 : 1836.99 €/m2

-

Primary energy need

50 kWhep/m2.an

(Calculation method : RT 2012 )

This project won the Health & Comfort Prize at the French and international levels of the Green Solutions Awards 2022-2023.

The Compagnons du Devoir et du Tour de France of Strasbourg expressed the wish to relocate their training center, because it no longer met expectations for training the professionals of tomorrow.

Indeed, the existing building was dilapidated and no longer met the standards in force and the needs for the reception of training staff.

This relocation has therefore become a necessity in order to attract young people to the trades offered by the Compagnons du Devoir.

This project to build a new training center has the strong ambition of being connected and innovative in the digital, energy and environmental transition .

Energy and comfort aspect

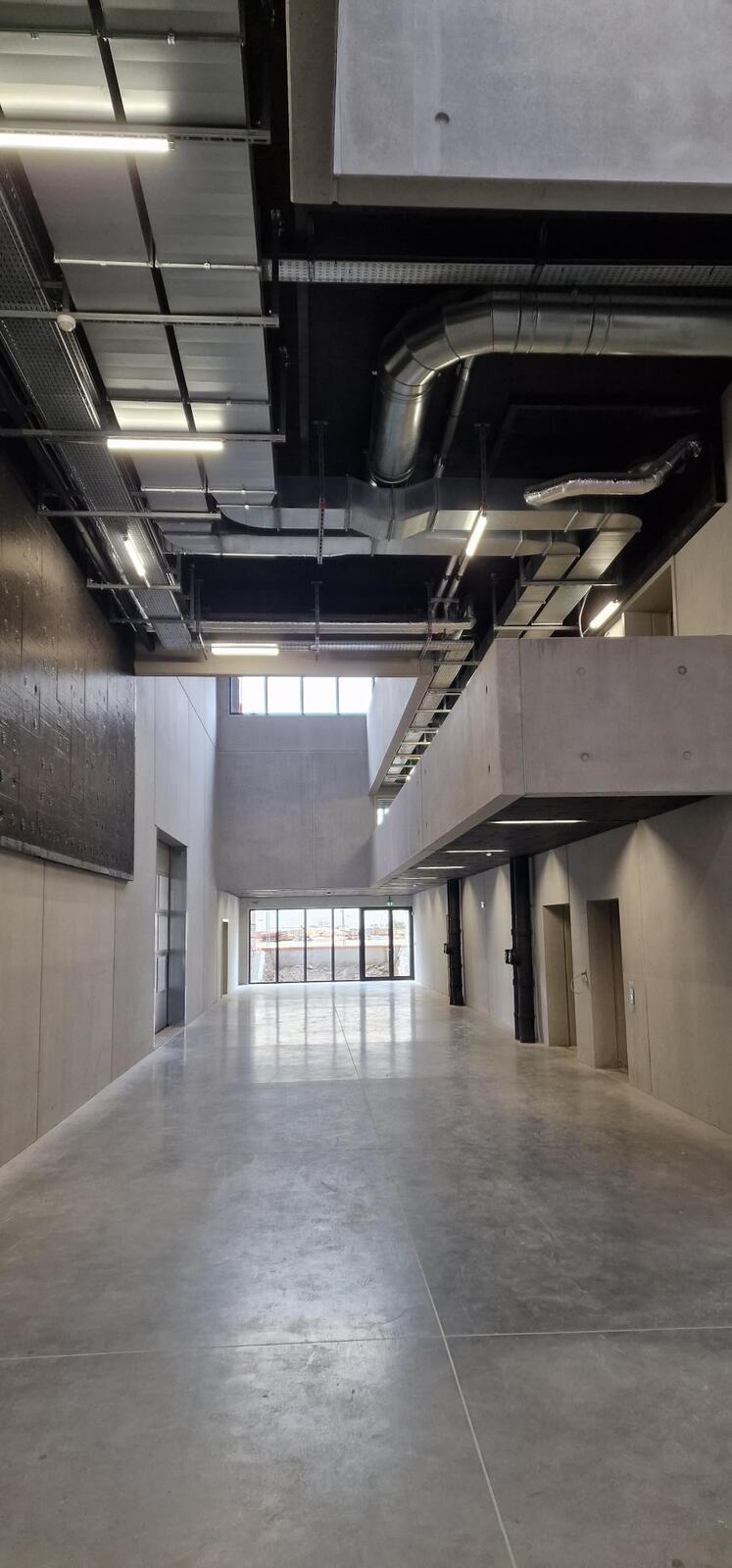

The project has the particularity of combining in the same building both a training workshop area and an administrative/teaching area.

The objective was to guarantee homogeneous comfort between the 2 entities, it means to push the energy design of the workshop area, in particular at the level of the thermal envelope and the airtightness, while taking into account the constraints linked to the different processes.

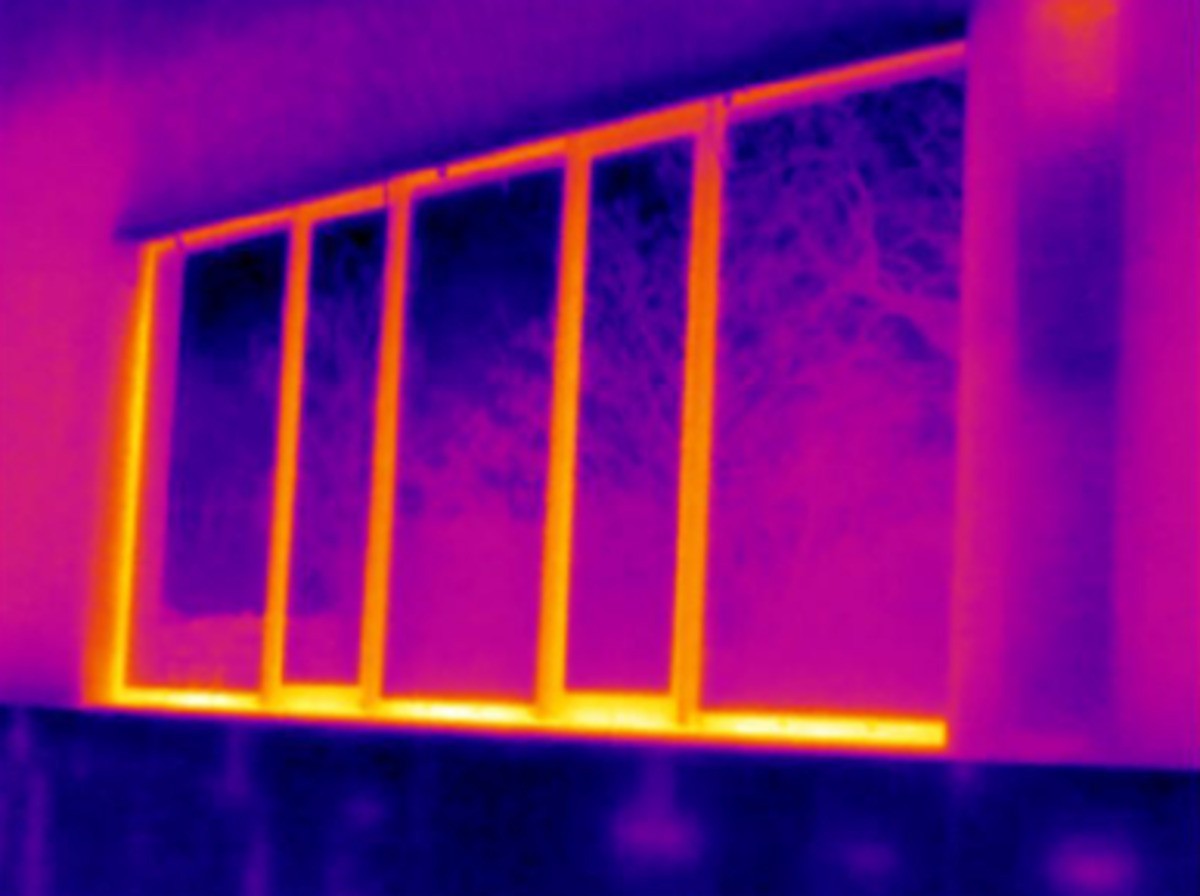

The building is therefore mainly designed in a concrete structure, in a non-metallic structure as usual (apart from two workshops upstairs), to guarantee efficient and continuous external insulation, good thermal inertia essential for summer comfort and excellent airtightness. The thermal resistance of the facades is uniform in the workshop and in the office (G>5) and all the low slabs are continuously insulated with 10cm of extruded polystyrene, even for the workshops.

Only two G+2 workshops (plumbing and roofing envelope workshops) have a metal facade with reinforced insulation (G=7). The self-protected steel deck roofs of the workshops were designed on the same principle, with great vigilance on the junctions with the airtightness plane of the envelope and with significant insulation.

Thanks to the implementation of a BIM model from the pre-project phases, the treatment of thermal bridges was more easily anticipated.

All of the joinery in the workshops and teaching rooms are double-glazed with reinforced insulation and are protected by automated adjustable sunscreens on the exposed facades (South, East and West).

The overall performance of the building is at RT2012 level -30%.

Air quality aspect

Given the proximity of the motorway air, air quality is also a major focus of the project design.

The shape of the J-frame provides protection for outdoor spaces from the highway. A study of the projection of fine particles has been carried out and an outdoor air pollution sensor will be installed in the heart of the building block in order to validate and measure the relevance of the simulations and the design of the building.

In addition, the administration part, the area closest to the motorway, is equipped with double flow ventilation with filtration of fresh air also guaranteeing good indoor air quality. Fresh air is taken from the north facade and opens into the heart of the building's green block.

The most sensitive classrooms in terms of intensity of use and number of people have been equippedindoor air quality sensor. If the threshold exceeds 1000ppm, an alert is sent to the user to create natural ventilation of the room.

The interior materials have been chosen to guarantee an air emission class of level A+.

Revegetation/rainwater aspect

Significant work has been done on the design of exterior coverings with a limitation of impermeable surfaces only to vehicle and technical access. The rest of the plot is vegetated, with in particular the establishment of beds made up of perennial plants and fruit trees, as well as grassed parking spaces and pedestrian paths in draining cobblestones. The installation of a composter is also planned.

The management of rainwater from sealed outdoor facilities is achieved by natural infiltration into green spaces via slopes. Given the constraints of soil permeability, rainwater from the roofs is connected to the public network via a retention.

Two workshop roofs are also planted to improve summer comfort for users and to buffer rainwater.

A 3 m3 recovery tank is also set up to supply a washing area, watering and maintenance of outdoor spaces.

Acoustic aspect

The journeyman training center has the dual characteristic of being a building whose internal activity (workshops, maneuvers in the inner courtyard) can be noisy, and of being located in a noisy environment. It is therefore necessary both to protect the neighborhood against internal noise, and to protect against external nuisances caused by the major neighboring roads.

The building is on the front line facing the A35 motorway (classified as category 1) on its eastern facade and facing the Route des Romains (classified as category 3) on its southern facade. To protect against these nuisances, the facades concerned are heavy, in reinforced concrete insulated from the outside, and equipped with joinery with a high level of acoustic performance. These heavy facades also protect the neighborhood from noise pollution from the workshops.

In addition, all truck maneuvers will take place inside the plot and the exterior evolution area of the structural work workshop will be limited by a 2.5m high concrete wall, acting as a wall. noise reduction with the neighborhood.

Concerning the internal acoustics of the project, the interweaving of workshops (noise-emitting premises) and classrooms requires specific treatment of the acoustics between premises. When the use of the premises allows it, a flexible floor covering makes it possible to limit impact noise in classrooms and offices. The implementation of an acoustic absorber in the ceiling of classrooms, offices and circulations contributes to the comfort of the premises.

The internal acoustics of the workshops, which are very high premises, are also treated with absorbent sound insulation bonded to the underside of the high floor and to two adjacent walls to control sound reverberations.

Building users opinion

The end users of the site have been fully integrated into the design of their future buildings. The employees were thus able, thanks to 5 meetings, to meet the architect and the design offices in order to discuss their expectations and needs in terms of ergonomics, acoustics, thermal, etc.

If you had to do it again?

Compagnons du Devoir

To be redone, we will deploy more widely the recovery of rainwater only allocated on this project to the structural work division (masons and stonemasons).

SOLARES testimonial (thermal and fluid design office)

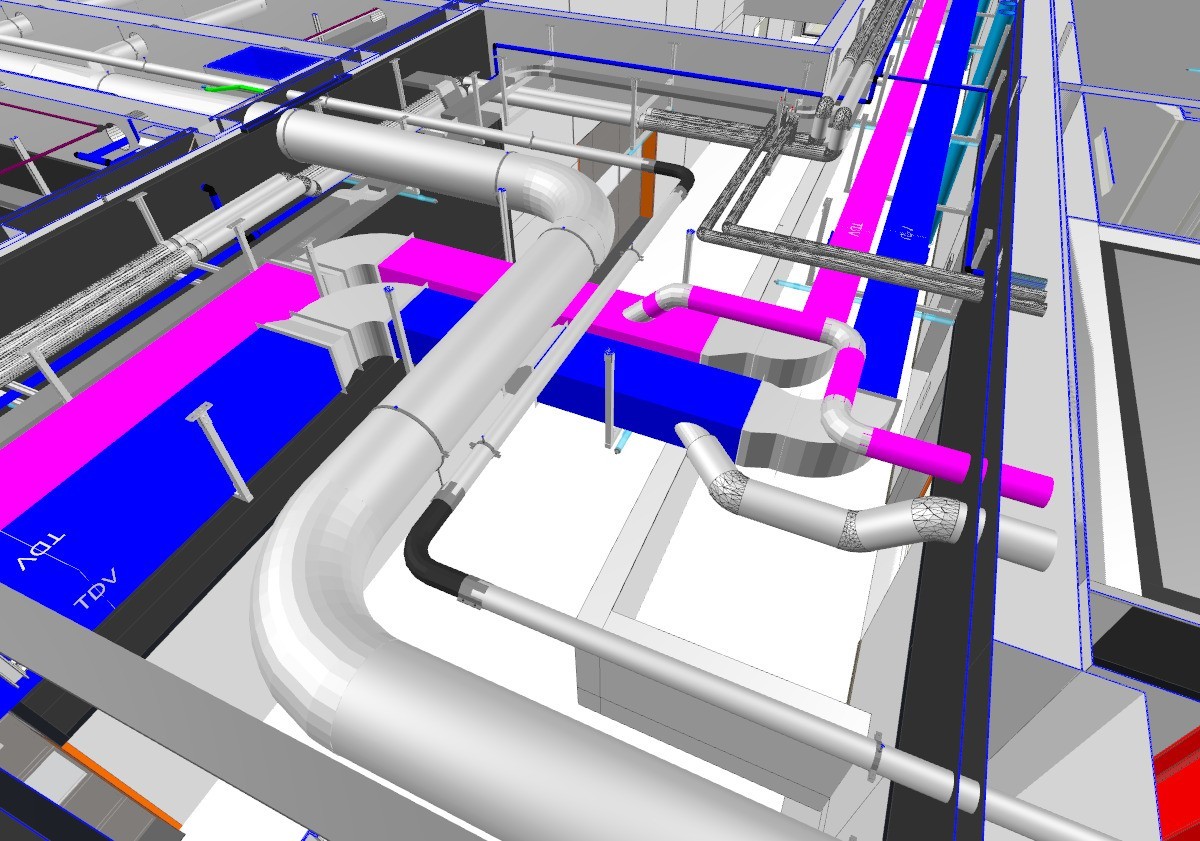

The interest of BIM on this project has been widely demonstrated. Indeed, given the multitude of networks running through the building (ventilation, process ventilation, electricity, water, sanitation, heating, special fluids (oxygen, acetylene, propane, compressed air), etc.), the digital model has enabled us to anticipate as many summary topics as possible before carrying out the work. It should also be noted that the Contracting Authority's involvement in this project has greatly facilitated these summary subjects, particularly as regards the interface with the machine park, the specific aspiration and the equipment of the taste division. The business meetings (end users) have also made it possible to respond as accurately as possible to the demand of trainers and learners, by offering a training center perfectly adapted to its uses.

Testimony of NUNC (Architects)

The training center project for the Compagnons du Devoir et du Tour de France was an opportunity for the Nuns agency to forge a real partnership with the companions.

We worked together, with each of the trades present on the site, on the ergonomics of the workshops and on the interior atmospheres, well helped by the digital model.

The trades had the opportunity to showcase their know-how by designing with us and manufacturing many elements of the project (reception furniture, furniture, wrought iron fences and gates, etc.).

BIM approach

Implementation of the process from the program phase

During the call for projects, in order to select a project management team, the contractor expressed in its real estate program the desire to integrate the BIM process and established its expectations on the BIM process and the final rendering of the project. From this competition phase, the 3 project management teams had to produce their rendering via a digital model, the presentation of the project is made in virtual reality.

Use of the digital model for performing dynamic thermal simulations

The use of the digital model was fully used for the design of the building, sunshine of the facades, bioclimatic construction, realization of dynamic thermal simulation, etc.

Realization of technical summaries throughout the design phase

In order to implement the BIM process, the planning of the design phase has been deepened by 40% compared to a site carried out without the BIM process.

Throughout the various stages making up the design phase the project contractor organized, with the construction management team as well as with the technical synthesis director, meetings in order to target and eliminate all the problems and conflicts present through all the digital models of the project. The objective of this synthesis work was to arrive at a project phase of an implementation level, thus allowing in particular the extraction of the quantities necessary for the drafting of the Breakdown of Total and Fixed Prices from the digital model. The production therefore does not stop at a pre-synthesis, but rather at a technical synthesis.

For more than 4 months, meetings were frequent in order to optimize the coordination, but also the design of the building. With the objective of optimizing spaces and volumes, this teamwork has made it possible to integrate into the Business consultation file common support for all fluids (HVAC, PLB, ELEC, etc.).

In total, these are more than 300 issues identified upstream of the implementation phase. All the technical synthesis was carried out via the BIMCollab Zoom solution and only via BCF format allowing, among other things, to annotate the models for a specific group (ex plumbers). In addition, the use of a viewer allows you to project yourself into the work that will be produced. The project review is done in virtual reality and technical synthesis from the Preliminary design phase.

Before the entry of the second work on the site, all the companies met with the organization, with the site and project management in order to identify and organize the sensitive areas in coordination of the project. The order of passage and intervention of each batch was decided, and this before arrival on the site.

A collaborative platform for centralizing up-to-date documents

To structure and supervise the dissemination of information related to the project, the AxeoBIM collaborative platform was selected. It allows you to create a tree structure in order to have the latest version of the documents and to codify them. To date, the collaboration platform includes 4 440 documents (invoices, plans, technical sheets, digital models, etc.). The 142 project stakeholders are connected and have access to the platform, including local authorities (Eurometropolis Strasbourg), CARSAT insurance and OPPBTP (the Professional Prevention Organisation for Building and Public Works).

Prefabrication of works

On this site, on average 70% of the works are prefabricated using the BIM process. The prefabricated works are the common supports, the structure, certain networks (HVAC-Plumbing), etc. The prefabrication of elements, facilitated by the production of digital models, has several advantages such as saving time on execution times, optimizing costsof construction and safety on the construction site, but also a real environmental gain. Indeed, prefabrication makes it possible to limit noise pollution, but also to facilitate the management of site waste. On this site, there are no dumpsters, it is the companies that take back their waste as they go. It is easier to use recyclable materials and the carbon footprint is reduced.

Moreover, it only took 4 days to install and seal the entire wooden frame (300 m² surface area) compared to a conventional construction site where around 3 weeks would have been necessary. The time saving is substantial.

In addition to saving time, it is also above all a considerable gain in embodied energy, and reduction of waste.

Reservation management

All reservation requests were also managed from the digital model. Each lot has integrated its reservation requests into its respective model. The reservation requests were then compiled and validated or not by the shell.

There are more than 700 reservations within the project. The inventory of reservation requests via digital model allows effective monitoring of their validation and implementation on site. This system allowed the site to take place without the slightest forgetting of reservations. Thus, contrary to what is common practice on construction sites, there was no work or additional costs related to forgetting to book.

BIM Prevention

In order to understand site risks and improve site installations, we modeled a digital model dedicated to prevention on the site, a site installation plan (PIC). This model allowed the companies to project themselves and organize their work on the site. It makes it possible to optimize pedestrian traffic areas, heavy and light vehicles, delivery areas and storage areas on the site.

As the building is on the edge of the property on the public space, the PIC also makes it possible to validate the operating methods in these sensitive areas of co-activity between the site and the public space, where bicycles and pedestrians are constantly walking. Thus, prevention is optimized for the actors of the construction site but also for the surrounding populations.

The PIC was also presented to CARSAT and OPPBTP in order to obtain their expertise and their recommendations on the planned site organization. This support has brought real added value, in particular as a support for exchange and understanding between each actor in the project. A risk prevention video on the site was produced from this digital model: each company or person wishing to carry out a site visit can thus view this video prior to any intervention.

Virtual visit

From the design phase, several exchanges were organized between the end users of the site and the project management group. The architect of the NUNC firm was thus able to identify the needs of the end users, the modeling of the machine park coupled with virtual reality also made it possible to optimize the surfaces and volume according to the need.

Here too, from the design phase, upstream of the execution and operation phase, the installation of terminal equipment is optimized. The professions can project themselves into the workshops to check the positioning of the machines and ensure that they correspond to their needs, both in terms of operation and safety.

QR code and NFC chip on site

Panels have been installed in each room of the construction site, making available a QR Code and an NFC chip. If the QR code or chip is scanned or badged from asimple smartphone, a 360° panorama rendering of the finished part appears. This innovation allows the works management to better discuss the work to be carried out, the workers to visualize the work as finalized, ensure better coordination and exchanges between the workers on site and also better project occasional visitors to the site.

Each plate is modeled and georeferenced in the digital model, thus allowing a geolocated 360° panorama thanks to the gyroscope function of smartphones or tablets. The virtual image is therefore perfectly aligned with the real site.

Augmented reality

The follow-up of the construction site and the reception of the works carried out according to the digital model are carried out thanks to augmented reality by the solution ''NEXT BIM''. The Microsoft hololens 2 helmet makes it possible to project a hologram of the digital model on the executed work to scale with automatic registration. It is therefore also possible to control and verify that the shaping of the structures complies with the digital model in order to partially validate the digital file of completed works and our maintenance operation needs.

This technology also makes it possible to check that nothing has been forgotten on the site before the execution of certain works, for example: forgetting a reservation or an engraving, etc.

BIM on the construction site

Each site manager is equipped with a phone or tablet and the ''DALUX'' solution for monitoring and viewing the model on the site. This solution allows each company to visualize the digital models, anticipate the coordination, visualize the finished work with all the technical trades. This solution also allows the production of cuts, side shots, which can be used by the worker in the event of quotation or missing detail on his execution plans.

Digital record of works executed and operation maintenance

The final objective after execution of the work is the evolution of the models towards a digital file of completed works. This will be done in particular by integrating operating parameters into the digital models. These parameters are already identified in the BEP ''BIM Execution Plan'' of the project.

Once the digital file of completed works has been validated for each model of the project, the link with computer-aided maintenance management (CMMS) is planned. The CMMS solution is currently being selected; it will be particularly useful for extracting the information necessary for the operation and maintenance of the sites. It will also allow the setting up of preventive and curative maintenance plans.

Photo credit

NUNC

AOCDTF

Contractor

Construction Manager

Stakeholders

Thermal consultancy agency

SOLARES BAUEN

Coralie OCHS - ochs[a]solares-bauen.fr - 03 88 30 97 74

https://www.solares-bauen.frThermal Study - Environmental - STD - Fluid

Other consultancy agency

Ingenierie et Developpement

Morgane CHRIST - morgane[a]bet-id.com

https://www.bet-id.comGTB / GTC study

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 50,00 kWhep/m2.an

Envelope performance

- 0,45 W.m-2.K-1

Systems

- Low temperature gas boiler

- Heat pump

- Aerotherm Heater

- Low temperature gas boiler

- Adiabatic cooling

- Nocturnal ventilation

- compensated Air Handling Unit

- Double flow heat exchanger

- Solar photovoltaic

- Biogas boiler

- Heat pump

- 110,00 %

Smart Building

Biodiversity approach

Risks

- Flooding/Slow flood

- Flooding/Fast Recession

- Urban heat island

- Heatwave

- Implementation of a vegetated block heart;

- Management of rainwater and risk of flooding by retention of underground water;

- Implementation of a summer scenario for heat waves (free cooling, reinforcement of vegetation, green roof, sunscreens with bioclimatic management, adiabatic cooling, fresh air intake on the North side).

Urban environment

- 6 502,00 m2

- 2 793,00 %

- 1 700,00

Product

Photovoltaic solar panels

VOLTEC SOLAR

https://www.voltec-solar.com/Structural work / Passive system

Implementation of photovoltaic solar panels for self-consumption plus resale.

Vegetalized roof

VEGETOIT

https://www.vegetoit.com/Technical summary

BIM Collab Zoom

https://www.bimcollab.com/fr?_gl=1*13jh8ge*_up*MQ..&gclid=Cj0KCQiA6fafBhC1ARIsAIJjL8mJIDjdDvfhgfah4ZdFuAXFIh6t0dVEBbgVeF79JGyn8MXOZe_nHOsaAskiEALw_wcBManagement / Others

Solution used for the intensive realization of almost 5 months of technical synthesis, the desire to achieve a tender documents at a level of execution in order to promote the prefabrication of the works and the extraction of the actual quantities to be used and deployed, thus aiming reduce waste and optimize the work process of workers on site.

Thermal bridge report

Solares BAUEN

Management / Others

Measurement at the end of construction and during the winter period: combing through the thermal camera of the building to check the quality of execution and compliance with construction principles.

Construction and exploitation costs

- 11 483 000 €

Water management

Indoor Air quality

Comfort

Life Cycle Analysis

Reasons for participating in the competition(s)

Ce projet est pionnier pour les Compagnons du Devoir mais aussi pour le milieu de la construction, les objectifs suivants sont pleinement intégrés à la directive globale du projet et sont suivis quotidiennement :

- L'optimisation de la conception des bâtiments (thermique, acoustique, QAI, environnement, etc.) ;

- La maîtrise de l'exécution ;

- La gestion et optimisation des modes opératoires et organisation du chantier (prévention) ;

- L'économie des ressources et la réduction des déchets ;

- La favorisation de la préfabrication grâce à la maquette numérique (BIM) ;

- L’optimisation de la collaboration ;

- Une meilleure gestion de l'exploitation du parc immobilier de l’AOCDTF via une GTB/GTC GED et GMAO ;

- Un support pédagogique à taille réelle pour les formations des Compagnons du Devoir et pour les jeunes générations (bâtiment exemplaire).

Grâce à la volonté et compétence de tous les acteurs du projet, cette construction est la réussite parfaite de la transition numérique, énergétique et environnementale que vit le milieu du BTP.

Nous souhaitons participer à ce concours afin de partager notre retour d'expérience, montrer que oui c'est possible ! Donner l'envie et l'exemple aux plus jeunes. Les métiers du bâtiment sont passionnants et la mise en œuvre des savoir-faire de chacun permet de répondre aux enjeux d'aujourd’hui et de demain !