Valorization unit

Last modified by the author on 20/11/2023 - 10:02

New Construction

- Building Type : Factories

- Construction Year :

- Delivery year : 2023

- Address 1 - street : 2 rue du Cardo 62073 BAILLEUL-SIR-BERTHOULT, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 1 435 m2

- Construction/refurbishment cost : 2 800 000 €

- Number of Installed Kw : 3 Installed Kw

- Cost/m2 : 1951.22 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : )

The LFB (French Fractionation and Biotechnology Laboratory) is building a “new generation” plant in the Actiparc area near Arras to produce plasma-based medicines in France for the whole world, used as treatments for many diseases.

As part of the construction of the site, LFB wanted to dedicate a building dedicated to the management of its waste and other by-products from production. The recovery unit makes it possible to transform an infectious by-product from the production building into a source of recycled raw materials made up of unmarked plastic flakes.

In order to extend its circular economy approach beyond the actual function of the building, LFB wanted to design a building with low environmental impact, under the prism of the circular economy.

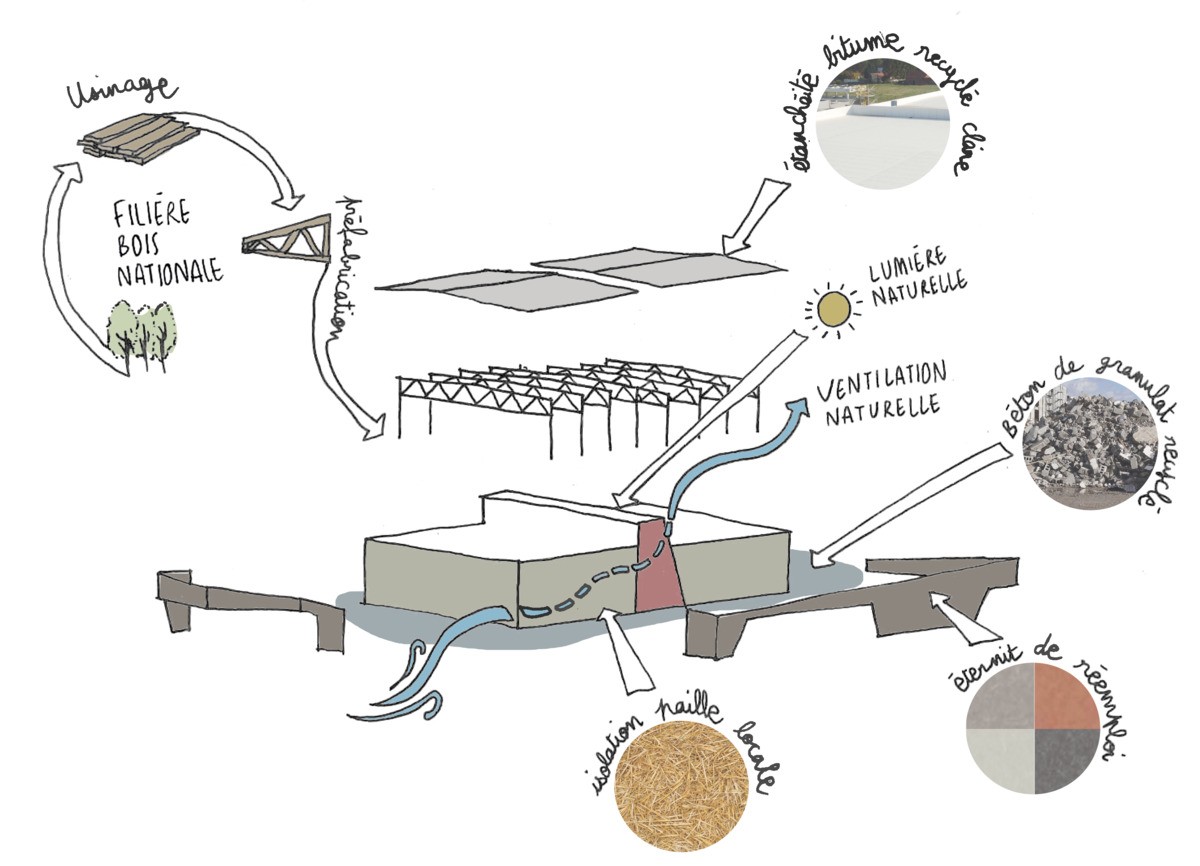

Environmental approach: matter and energy

The project pays particular attention to the construction materials considered. It promotes biosourced materials, from recycling, reuse and local channels:

- The structure of the building is entirely in Douglas wood frame from national sectors;

- The envelope is made up of wooden frame walls with straw filling;

- The facades are made up of Eternit panels from the end of stocks intended for the recycling centre;

- The waterproofing of the light-coloured cover to prevent overheating is made of recycled and recyclable materials;

- The concrete slab is made up of 50% recycled aggregates from a demolition site less than 40km away;

- The insulation of the partitions is made of métisse manufactured less than 40km

With a view to saving material in the short and medium term, all the construction materials are carefully implemented so as to remain raw: quartz concrete paving, exposed breeze block walls for the storage rooms, raw Fermacell panel on the interior facade walls, etc.

In order to reduce the energy necessary for its operation, the project uses the resources available on the site, resulting from the activity of the factory. Heating needs are recovered from the heat generated by the recovery process within the building. The supply of the machines necessary for the recovery process uses the compressed air network produced on site.

Bioclimatic approach

The design of the building promotes bioclimatic systems by invoking natural and passive resources to meet thermal, hygrometric and air renewal needs.

Located on the plains of Artois largely exposed to the winds, the building benefits from a natural ventilation system allowing natural sweeping of the process, a source of heat. The grids ofventilation located in the lower part of the South-West facade, exposed to the prevailing winds, allow the air to circulate in the heart of the building up to the chimney which, under the draft effect, evacuates the hot air in the upper part . Mechanical ventilation is provided in addition in case of high temperatures.

The ventilation system is regulated via interior temperature sensors and a weather station on the roof.

Like industrial sheds, the volume of the chimney also allows a supply of zenithal light on the North side to avoid overheating.

Rainwater collected from the roofs is stored in a tank to be used for building maintenance and washing the bins that transported the by-products.

Volumetric principles

The building is composed of a compact primary envelope hosting the by-product recovery process. Its French glued laminated Douglas wood frame structure gives it large spans to make room for a large open volume. In order to limit energy expenditure and improve user comfort, the building envelope is fully insulated by wooden frame walls with straw filling.

A second volume wraps around this envelope to form a canopy, necessary for the protection of storage and deliveries.

Principles of facades

The cladding envisaged for the facade was the subject of a partnership with the supplier Eternit to identify and recover end-of-series stocks, taken out of the market and intended for the waste disposal center in the near future.

The design of the facades was therefore done in the opposite way to the customs of the prescribers that we are, in the sense that the composition of the colors and the layout was thought out from the available stocks. The layout of the facades favors small modules at the foot of the building to facilitate their replacement in the event of damage over time.

Building users opinion

This building is efficient, scalable and a concrete action of the company's CSR approach.

If you had to do it again?

For the building, we did not succeed in using poplar construction wood in the local sector, despite discussions with suppliers upstream of the consultation of companies, no official reservation of stocks has been initiated by the Control of work which feared the additional cost during the call for tenders. Finally, the cost was not higher than the French Douglas sector (New Aquitaine region), but the delivery time announced by the supplier caused a delay on the site of 6 months. The construction wood therefore comes from the New Aquitaine region.

Photo credit

BLAU

Contractor

Construction Manager

Stakeholders

Assistance to the Contracting Authority

NEO ECO

Maude SOUBEIRAN, msoubeiran[a]neo-eco.fr

https://www.neo-eco.fr/AMO circular economy

Structures calculist

INGEBOIS

Laurent LEPAUL, laurent.lepaul[a]ingebois.com

https://ingebois.com/Studies of wooden structure and wooden facades

Structures calculist

MBA Structure

Omar SEYDI, omar.seydi[a]mbastructure.fr

https://www.mbastructure.fr/Concrete structure studies

Thermal consultancy agency

TWI ingénierie

Julien FROGER, julien.froger[a]tw-ingenierie.com

https://www.tw-ingenierie.fr/Fluid studies, plumbing, thermal

Other consultancy agency

PROJET

Laurent Versalie

Electrical studies

Company

SATELEC

Richard Dendauw

Electrical studies

Company

SNPC

Florimond LEPOUTRE

Road studies, networks

Contracting method

Lump-sum turnkey

Type of market

Not applicable

Allocation of works contracts

Separate batches

Energy consumption

Envelope performance

More information

No feedback yet, building not currently in operation. The industrial process machines will only be installed in 2024.

Systems

- Electric radiator

- Other hot water system

- No cooling system

- Natural ventilation

- No renewable energy systems

Urban environment

Product

Low carbon concrete slab

GCC / PLACEO / EQIOM

Second œuvre / Revêtements de sol

GCC produced with PLACEO as a subcontractor the interior paving composed of 50% recycled aggregates and the exterior paving composed of 30% recycled aggregates.

The formulations have been developed in partnership with EQIOM and have been certified by the control office. In particular, durability tests were carried out.

Construction and exploitation costs

- 300 000 €

- 2 800 000 €

- 360 000 €

Circular economy strategy

- Maximization of quantities on targeted products

Reuse : same function or different function

- Facades

- 2,300 m²

- End of series of Equitone supplier not marketed

- Reuse in facade cladding

Logistics

- No problem of storage, supply correlated to the progress of the works

Insurance

Environmental assessment

Economic assessment

- 203 000 €

- Others

Communication

Circular design

- Use of energy produced for the entire LFB site (example: use of compressed air produced for the entire site for our building);

- Industrial process recovering infectious risk waste from LFB production which, until now, was sent to a treatment center;

- Use of natural resources to meet the energy needs of the building (natural ventilation, recovery of rainwater for the industrial process, favoring the contribution of natural light, no heating for the main hall which will be naturally heated by the energy released by the machines, etc.);

- Pooling of living bases to all buildings under construction on the LFB site.

- Recyclable clear waterproofing membrane;

- Use of recycled cotton insulation for the interior walls (Metisse);

- Concrete composed of recycled aggregates (50% for the interior slab and 30% for the exterior slab). Tests were carried out by test specimen during studies by Neo Eco in partnership with Eqiom in order to develop the formula of the concretes used.

Additional information (PDF documents)

Reasons for participating in the competition(s)

We are competing in the Green Solutions Awards 2022-2023 competition and the Circular Buildings Trophies because they convey in all respects the actions that we have carried out on the recovery unit with the FBL.

The design of the building followed the virtuous approach of the Client to create a building that recycles the waste resulting from its production, it is therefore natural that the design choices fell on the principles of the circular economy and the bioclimatic architecture. The building was designed to consume little (example of an efficient envelope insulated with straw) and the energy necessary for its operation comes mainly from natural resources (wind, rain, sun). The choice of materials has been oriented towards recycling, reuse or bio-sourced channels, they are locally sourced as much as possible. The fire regulatory aspect (some exterior facades must comply with REI60 resistance) has been studied to allow the use of straw on the facade. The will of the Project Management and Project Management team has focused on a low-carbon demonstrator industrial building, which participates in the development of local sectors and which constitutes feedback for other manufacturers who would like to take the same approach. In addition, the Contracting Authority wishes to organize regular visits to the building in operation in order to raise awareness among the general public, manufacturers and building specialists.

Building candidate in the category