From the laboratory scale to the industrial scale

Create a subpage- Alexia ROBIN

- /

- the 11-02-2019

- / 1988

The SB&WRC project is part of the Programme Interreg VA France (Channel) England and benefits from financial support from the ERDF

|

|

|

The last phase of the SB&WRC project consists of a test phase of prototype 1 under real conditions of use. The realisation of these tests is determined by a first stage of prototype 1 production on a large scale. Prototype 1, based on corn marrow, is produced by thermocompression. The purpose of the thermocompression process is to shape a planar material under the combined action of heat and pressure.

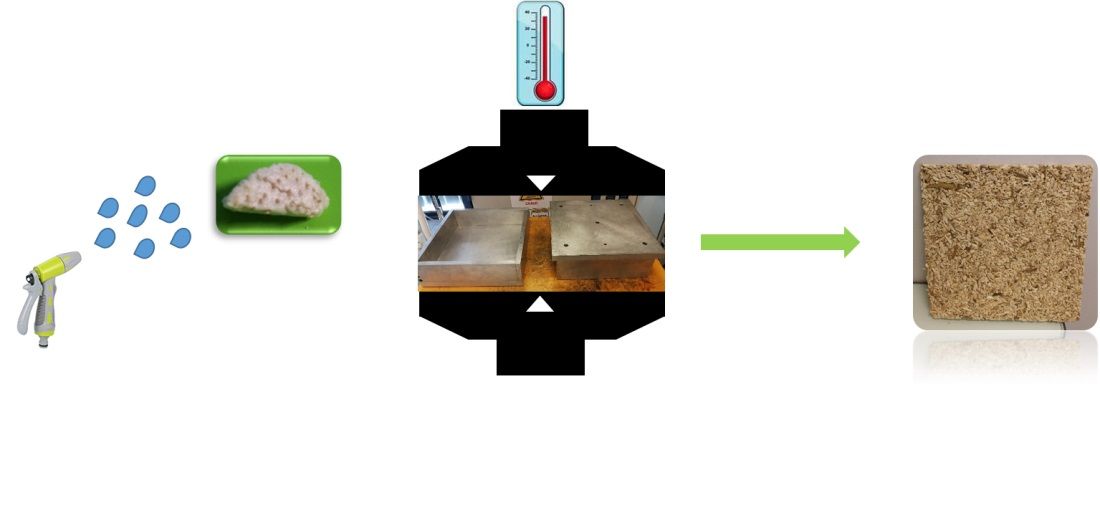

On a laboratory scale, the humidified corn marrow is placed inside a mould that undergoes thermocompression (figure 1). The obtained prototype is a 30cmx30cm panel.

Figure 1: Development of prototype 1 at laboratory scale

Carrying out tests under real conditions of use requires 1.1mx1.1m panels.

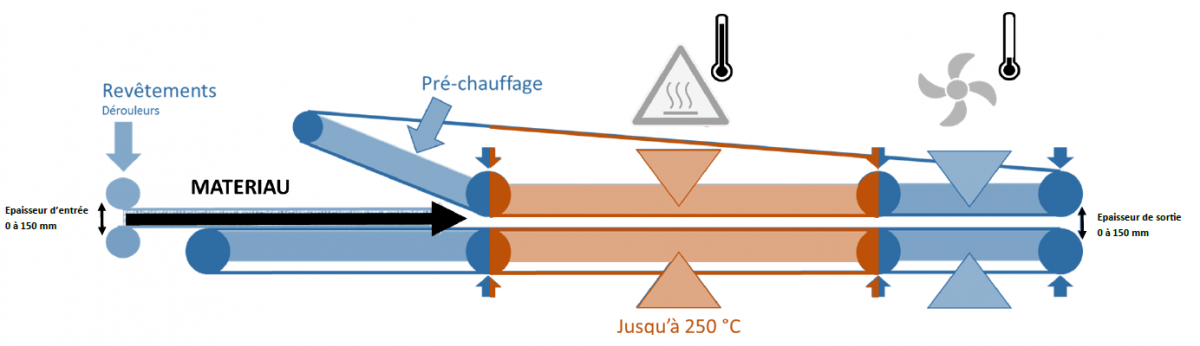

To test our prototype on a large scale, we use a continuous heating press (Figure 2). The raw material is placed on a teflon coated moving belt. The material is driven into a first pre-heating area, at the end of which the pressing starts within a heating area for 6 minutes. The pressing continues in a cooling zone for 3 minutes.

Figure 2 : Continuous heat press

The results of these first scale transfer trials are promising, as we have successfully developed 1.1mx1.1m corn marrow-based panels (Figure 3). Trials continue to optimise our formulation, for example by decreasing the amount of water, that is difficult to eliminate on this type of press. The panels we formulated have been sent to our partner, at the University of Bath, that will soon perform hygrothermal tests under real life conditions.

Figure 3: 1.1mx1.1m corn marrow-based panels