The Grande Halle de Colombelles

Last modified by the author on 11/06/2021 - 10:37

Renovation

- Building Type : Other building

- Construction Year : 1917

- Delivery year : 2019

- Address 1 - street : Rue des Ateliers 14460 COLOMBELLES, France

- Climate zone : [Cwb] Mild, dry winter, cool and wet summer.

- Net Floor Area : 3 650 m2

- Construction/refurbishment cost : 5 800 000 €

- Number of none : 1 500 none

- Cost/m2 : 1589.04 €/m2

-

Primary energy need

41 kWhep/m2.an

(Calculation method : RT existant )

Third place of the circular economy

Last vestiges of the gigantic Société Métallurgique de Normandie (SMN) whose blast furnaces were established in 1917 on the Colombelle plateau north-east of the agglomeration of Caen, the electrical workshop and the vertiginous refrigerant are the last symbols physical aspects of this burning history, the last casting of which took place in 1993. In order to reconvert the site, SEM Normandie Aménagement has initiated a collaborative approach, and imagined the future of this large concrete hall into an innovative workplace and culture that more particularly welcomes players in the collaborative and circular economy.

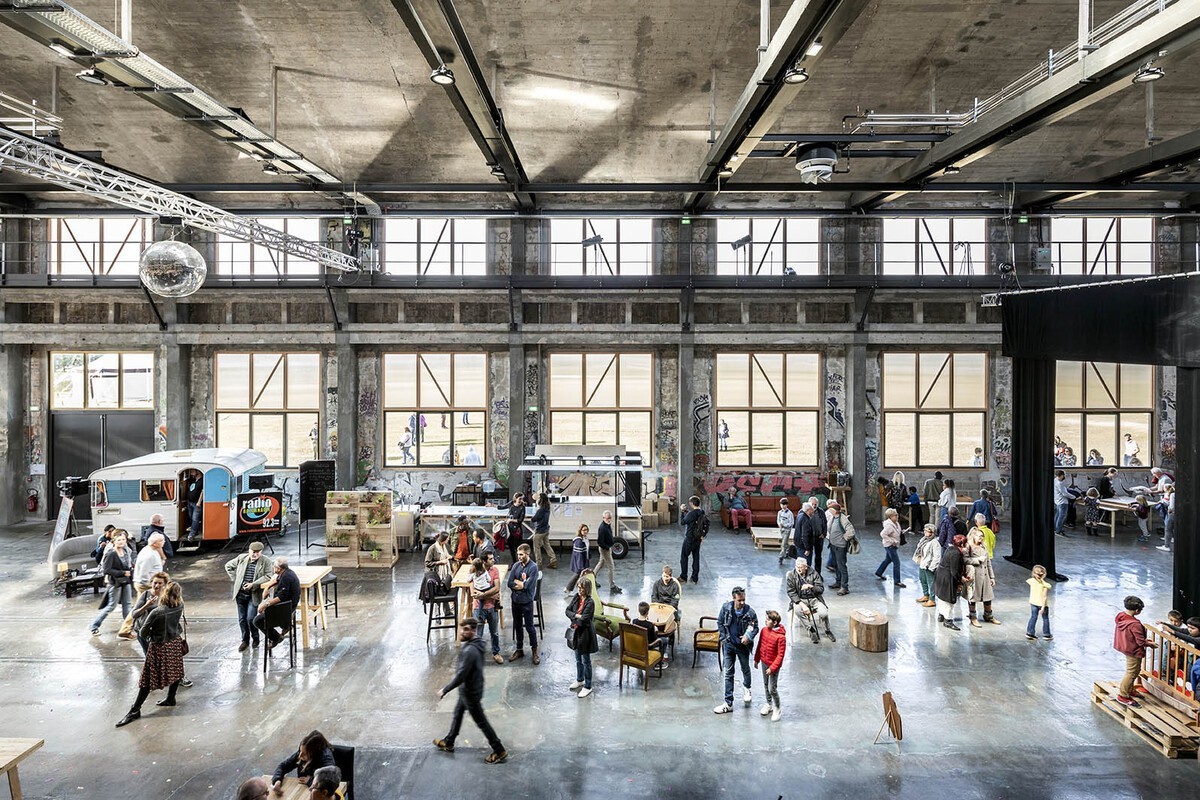

The envelope carrying memory is repaired but generally preserved. Inside the small nave are three wooden levels with a café-restaurant and workshops on the ground floor, collaborative workspaces and rehearsal spaces on the upper floors. Large wooden balconies extend these corbelled workspaces over the large nave, which has been left almost as it is. It is the meeting place and gathering place of the Grande Halle, hosting all types of cultural or professional events.

La Grande Halle was the opportunity to apply an ambitious approach to reusing construction materials in the context of an ERP building. With a process involving all stakeholders, from project management to companies, many elements of the Grande Halle thus come from deconstruction sites in the region: radiators, toilets, wood, earthenware, windows and fire doors….

Foreshadowing a construction method put in place for the Grande Halle, the ETC collective has created the Cité de Chantier at the foot of it from materials resulting from reuse. She welcomed the users by foreshadowing the functioning of the place.

Sustainable development approach of the project owner

Normandie Aménagement takes the sustainable approach to its heart in the various operations it carries out.

Through the first two labeled eco-neighborhoods developed on the CU Caen la mer (by including in particular an in situ nursery in order to revegetate the neighborhoods on site), the enhancement and requalification of industrial-port wasteland in order to renew the city on it. even, as well as through its real estate development operations by always going further in the design of efficient, sustainable and inclusive buildings (E + C- and RE 2020).

Through this virtuous and emblematic operation of the Grande Halle, Normandie Aménagement invites us to question our construction and rehabilitation techniques. Making it possible to experiment, on this scale, with the reuse of materials by devoting a dedicated market batch to it, demonstrates the collective and partnership capacity to broaden the field of possibilities.

Questioning the future of buildings at the time of their design (deconstruction, reversibility, etc.) are project approaches that are spreading for the future of our territories and of those who live there and will live there.

Architectural description

The original envelope, carrying memory, consisting of two concrete naves, has been preserved and repaired. Inside the small nave were built two wooden levels that slide into it, with a café-restaurant and workshops on the ground floor, collaborative workspaces and rehearsal spaces on the upper floors. Large wooden balconies extend these corbelled workspaces over the large nave, which has been left almost as it is. It is the place of meetings and gatherings welcoming all types of cultural or professional events.

The investment was concentrated on uses and working comfort, leaving the continuation of the appropriation of facades to local graffiti artists.

If you had to do it again?

Discussions with the craftsmen who took part in the construction (separate building trades) revealed a great interest on their part in reuse practices. The majority of them said that if given the opportunity, they would again respond to a market for the implementation of re-used materials.

See more details about this project

http://encoreheureux.org/projets/grande-halle/Photo credit

Cyrus Cornut

Contractor

Construction Manager

Stakeholders

Site manager

Le WIP

ophelie[a]le-wip.com

https://www.le-wip.com/Control of use and users of the Grande Halle

Environmental consultancy

Aubry et Guiguet

https://agstudio.fr/studio/Programmer

Designer

Construire

http://construire-architectes.over-blog.com/Environmental consultancy

Motta Paysagistes

http://lilianamotta.fr/Landscaper and reclamation of polluted land

Other consultancy agency

Cap Exe

OPC

Other consultancy agency

Albert et Compagnie

https://albert-and-co.fr/Environmental design office

Structures calculist

Ligne BE

Other consultancy agency

T&E Ingénierie

Fluid design office

Environmental consultancy

ECRH

Economist

Other consultancy agency

Ateve Ingénierie

https://www.ateveingenierie.com/VRD

Type of market

Global performance contract

Energy consumption

- 41,00 kWhep/m2.an

- 97,00 kWhep/m2.an

- 163,00 kWhep/m2.an

Real final energy consumption

41,00 kWhef/m2.an

Systems

- Wood boiler

- No domestic hot water system

- No cooling system

- Natural ventilation

- Wood boiler

Urban environment

- 36 000,00 m2

Construction and exploitation costs

- 320 000 €

- 5 800 000 €

Reuse : same function or different function

- Structural framework

- Indoor joineries

- Outdoor joineries

- Floorings

- Isulation

- Heating ventilation air conditioning

- Plumbing

- others...

Environmental assessment

Economic assessment

- 146 000 €

- 2 %

Life Cycle Analysis

Reasons for participating in the competition(s)

The Grande Halle project is particularly interesting and innovative from the point of view of the circular economy; it is indeed the first building to set up a lo t01 entirely dedicated to reuse, in order to support companies likely to be affected by the reuse of materials throughout the worksite. It was also the site of the constitution of a CCTP with variant, known as "with holes", which came to facilitate and standardize the setting up of large-scale reuse. These innovations then become very replicable, because they emerge from a very adaptable construction methodology. In addition, it is about a project which was the place of the installation of a very important quantity of materials of reuse.

Building candidate in the category