Re:Crete Footbridge

Last modified by the author on 19/05/2022 - 09:13

New Construction

- Building Type : Other building

- Construction Year : 2022

- Delivery year : 2022

- Address 1 - street : Rte Cantonale / Rte de la Morge 1964 CONTHEY, Suisse

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 12 m2

- Construction/refurbishment cost : 67 000 €

- Cost/m2 : 5583.33 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : )

Re:Crete, designed and built by EPFL's Structural Xploration Lab (SXL), is a footbridge made of concrete blocks saw cut from the walls of a building under renovation and reassembled into a post-tensioned segmented arch. Created as a research prototype, this footbridge demonstrates for the first time the feasibility of reusing concrete elements extracted from a cast-in-place structure in a new load-bearing structure. Concrete is the most widely used building material in the world and is a major source of the construction industry's environmental impacts. Reusing saw cut elements extends the use life of obsolete concrete. It avoids its premature crushing, while reducing greenhouse gases, demolition waste and raw material extraction.

In collaboration with the State of Wallis, in Switzerland, the prototype could be installed over the Morge river for a period of 2 years, where it is accessible to the public. The structure was therefore equipped with handrails, also made of reused materials. It is used for pedestrian mobility during the construction works on the adjacent road bridge.

The concrete blocks are extracted from the walls of the source building using a circular diamond saw. The sides of the blocks are then drilled to allow the passage of the post-tensionning cables. For the assembly of the arch, the blocks are placed on a timber centering and the post-tensioning ducts and cables are threaded through the side holes. Before tensioning the cables and removing the centering, the joints are filled with mortar to ensure contact between each block. To make the footbridge permanent and suitable for outdoor use, the exposed cut rebars were covered with an anti-corrosion paint, a hydrophobic impregnation was applied on the concrete faces and the joints were covered with waterproofing strips. However, the characteristic texture of sawn concrete, showing aggregates and rebars, remains visible on the side faces of the arch. The materiality of the bridge expresses both the source of the material, with its own history preceding that of the bridge, and the technique used to implement it. Finally, the railing was made with metal tubes from obsolete festival tents and steel wire meshes from shop furniture.

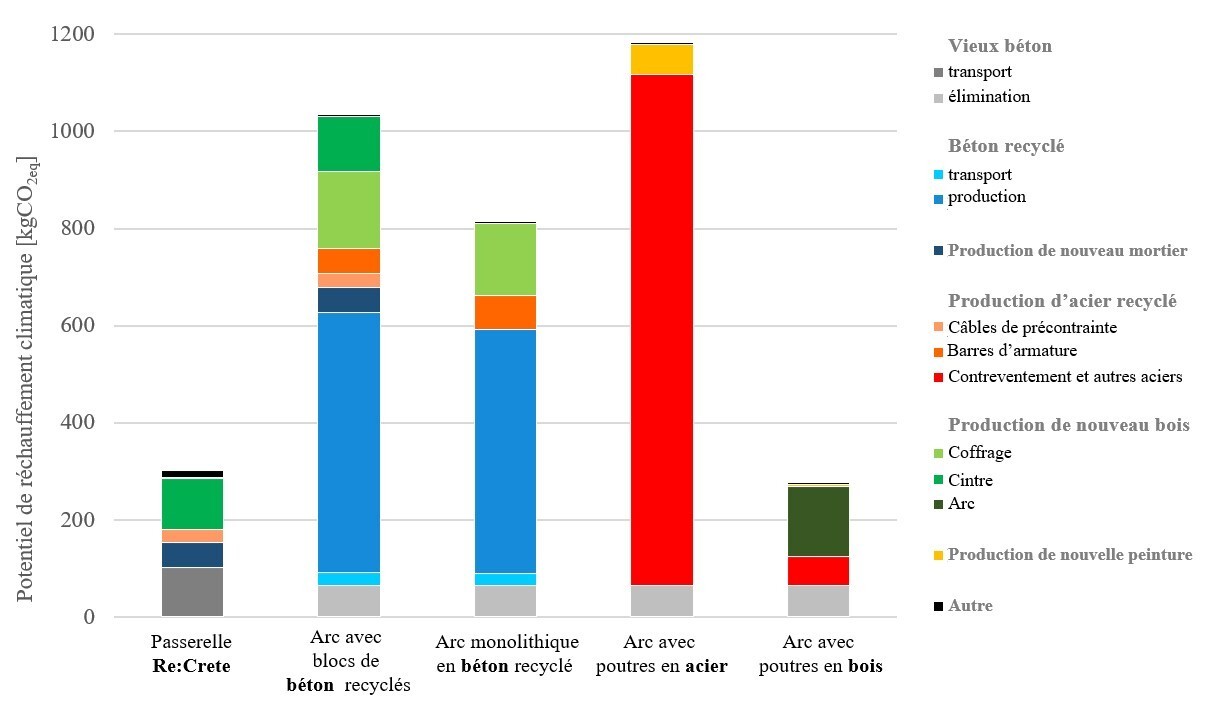

Besides providing a new design material for architects and engineers, the reuse of concrete elements is an effective solution to reduce the demand for cement, CO2 emissions and concrete waste. A detailed life cycle analysis shows that the Re:Crete footbridge has a lower environmental impact than similar solutions in reinforced concrete (-63%) or steel (-75%) and approximately similar to that of a solution in new timber (+9%).

If you had to do it again?

This pioneering experience of reusing concrete elements extracted from a cast-in-place structure confirmed a new way of designing structures. The technologies used (e.g. concrete sawing and post-tensioning) proved to be appropriate for the reuse of concrete blocks to design a new structure. Nevertheless, we have identified ways to further increase the environmental benefits of the approach:

- Minimization of transport distances for reused materials

- Verification of the properties of reused materials before their deconstruction or acquisition

- Minimization preparation work required on the reclaimed concrete elements

- Consideration of the durability of reused concrete through adequate construction details

See more details about this project

https://www.epfl.ch/labs/sxl/index-html/research/reuse-of-concrete/Photo credit

Ecole Polytechnique Fédérale de Lausanne (EPFL), Structural Xploration Lab (SXL)

Contractor

Construction Manager

Stakeholders

Company

Diamcoupe SA

Guillaume Mittnacht (chef de région, Suisse Romande)

https://diamantbohr.com/fr/The Diamcoupe company supplied and prepared the concrete blocks. It sawed blocks in the walls of the source building and drilled cores for the passage of prestressing cables.

Company

Freyssinet SA

Adrian Motte (directeur d'agence, Suisse)

https://www.freyssinet.com/Freyssinet supplied the sheaths and prestressing cables. It proceeded with the tensioning of the cables and the injection of the sheaths.

Environmental consultancy

Bridgology SA

Alexis Kalogeropoulos (fondateur et directeur)

https://bridgology.com/fr/Bridgology carried out non-destructive measurements on the structure to determine the cover of the pre-existing reinforcing bars and check the condition of the concrete.

Company

Sika Suisse SA

Cédric Chetelat (ingénieur conseil, Suisse Romande)

https://che.sika.com/fr/home.htmlThe Sika company supplied the products applied to the footbridge to protect it from water (anti-corrosion paint, hydrophobic impregnation, sealing strips).

Company

Emil Egger Romandie SA

Frédéric Marilley (chef de projet)

https://www.ete.ch/fr/Emil Egger transported the footbridge from its manufacturing site in Friborg (Switzerland) to its installation site in Conthey (Switzerland). It also carried out the lifting for the installation of the footbridge over the river.

Systems

- No heating system

- No domestic hot water system

- No cooling system

- Double flow

- No renewable energy systems

Risks

- Frost

- the cut rebars, visible on the cut faces of the concrete blocks, were protected with anti-corrosion paint;

- the exposed concrete faces have been impregnated with a hydrophobe;

- the sheaths of the prestressing cables were injected with mortar;

- the joints were sealed with glued plastic strips.

Urban environment

Product

Diamcoupe SA

Guillaume Mittnacht (chef de région, Suisse Romande)

Gros œuvre / Structure, maçonnerie, façade

Freyssinet SA

Adrian Motte (directeur d'agence, Suisse)

Construction and exploitation costs

- 67 000 €

- 25 900 €

Reuse : same function or different function

- Structural works

- Locksmithing-Metalwork

- Concrete blocks: 2.43 m3

- Tie rod: 22 linear meters

- Steel posts and handrail: 40 linear meters

- Steel wire mesh: 44 m²

- Concrete blocks: sawn into the walls of a hotel basement undergoing transformation in the canton of Vaud, reused as the structure of the arch. Supplied by the sawing company.

- Sub-tie rods: salvaged from an EPFL structural testing hall in Lausanne, reused.

- Steel posts and handrails: come from an old marquee used for festivals. Retrieved from a resource center (https://www.la-ressourcerie.ch/ ).

- Trellis: from old industrial shelves. Recovered in a resource center (https://www.ecocube.ch/ ).

Environmental assessment

Economic assessment

- 19 200 €

- 29 %

GHG emissions

- 25,00 KgCO2 /m2

- 15,00 année(s)

- 25,00 KgCO2 /m2

Life Cycle Analysis

Reasons for participating in the competition(s)

The Re:Crete footbridge is an original project which integrates for the first time the structural reuse of concrete elements extracted from an existing cast-in-place concrete building. It demonstrates the technical feasibility while using technologies known by the construction industry such as concrete sawing and post-tensioning. To guarantee the long-term durability of reused concrete elements, the structure was adapted, by simple methods, to outdoor use. The railings are also designed with reclaimed materials.

Confirming that sawn concrete is a new reusable structural material, this project extends the application of circular economy principles to the construction industry. A new field of activity is created, where sawn concrete elements are used for the construction of traditional buildings. In addition, this first prototype convincingly demonstrates that the approach can drastically reduce greenhouse gas emissions, construction waste and raw material extraction. Its generalization offers new perspectives to quickly contribute to the mitigation of global warming and increase the sustainability of the construction industry.