Hangar Zero

Last modified by the author on 11/04/2022 - 10:37

Renovation

- Building Type : Logistics warehouse

- Construction Year : 1920

- Delivery year : 2022

- Address 1 - street : 37 quai de la Saône 76600 LE HAVRE, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 2 450 m2

- Construction/refurbishment cost : 1 078 000 €

- Cost/m2 : 440 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : Other )

This project won a mention for the Circular Economy Prize of the Green Solutions Awards France 2022-2023.

Hangar 0 - read "zero", for zero waste, zero embodied energy, zero carbon, zero exclusion - is a project to convert a wasteland port in Le Havre into a citizen laboratory for ecological transition.

This project, winner of Réinventer la Seine, consists of the redevelopment of a former coffee dock, on the edge of a river basin to accommodate activities centered on the circular economy and urban agriculture. A shop, a restaurant and two workshops and offices have already been delivered. Eventually, this third place will also include an aquaponic greenhouse, shared workshops, a Fablab , coworking spaces, shared vegetable gardens and a permaculture garden.

Its primary purpose is to mobilize innovative solutions to improve the resilience of the territory of the city of Le Havre . These solutions make it possible to raise residents' awareness of responsible consumption by bringing them closer to circular economy players who experiment, produce and transmit within the very heart of Hangar 0.

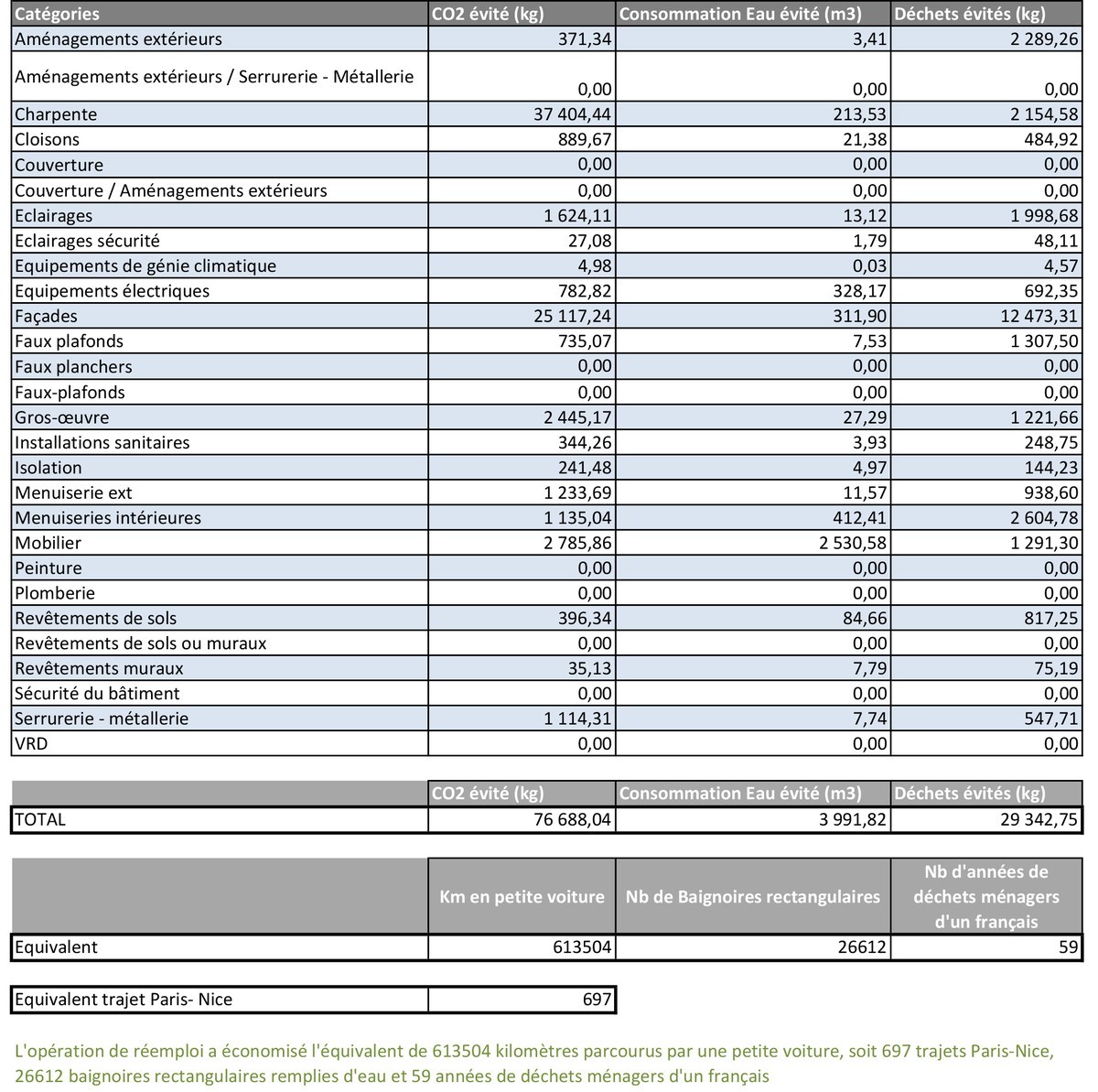

This third place revolves around several pillars of the circular economy, mainly reuse, eco-design, extending the duration of use and the management of waste as resources. Hangar Zéro has therefore set itself the objective of reusing 90% of the construction materials used for the development of the 2500m² site .

Building users opinion

The occupants participate in the design and construction of the place. Their opinion can vary greatly depending on their degree of involvement.

What emerges most often is the feeling of tremendous civic energy, but also that everything takes too long! Former future occupants, less involved in the realization of the project, have given up to join faster projects!

If you had to do it again?

Based on our experience, we would move towards a higher re-employment rate. We have a feeling of failure when, lacking reused wood resources, or steel, we were forced to buy a new part, so as not to delay the work.

See more details about this project

https://www.lehangar-zero.orghttps://www.facebook.com/lehangarzero

https://www.instagram.com/lehangar.zero

https://www.construction21.org/france/articles/h/green-solutions-le-hangar-zero-un-tiers-lieu-zero-dechet-zero-carbone-zero-exclu.html?n=20230510090156

Photo credit

ARCHIPELAGO ZERO

Contractor

Construction Manager

Stakeholders

Other consultancy agency

PERMAC

Brice Canaud et Steven Lemercier

https://www.linkedin.com/company/73221312/adminBET Reuse

Company

Lefebvre Industrie

Willy Lefebvre

https://lefebvre-industrie.frMasonry and structural work

Company

French-Line Cabine

Francois-Xavier Guyomard

Transformation of shipping containers

Company

Duchesne

Harold Duchesne

Exterior wood furnishings

Company

Abbei

https://abbei.org/Interior insulation

Company

EMMA

Matthieu Le Marchand

Metalwork

Others

La chaîne du Liège

Yves Sauce

https://www.facebook.com/La-Cha%C3%AEne-du-Li%C3%A8ge-188106371292400/recycled cork supplier

Contracting method

Other methods

Energy consumption

- 157,00 kWhep/m2.an

Envelope performance

More information

Ultimately, the premises of Hangar Zero will be heated using a water-water heat pump, using water from the river basin, and heat transfer from a 200 m² greenhouse. In the meantime, the delivered spaces are heated using closed and insert fireplaces, fueled with wood scraps from the construction site.

More information

The actual consumption of the building is unknown to date. As the building has a large part of unheated buffer spaces, the RT 2012 calculation is unsuitable.

Systems

- Heat pump

- Heat pump

- Others

- Others

- Free-cooling

- Single flow

- Solar photovoltaic

- Heat pump

Urban environment

- 2 200,00 m2

- 39,00 %

- 1 300,00

Product

La chaîne du liège

lachaineduliege[a]gmail.com

https://www.facebook.com/profile.php?id=100064801025861Second œuvre / Cloisons, isolation

Bulk cork, recycled from shredded cork stoppers, is used as insulation between the facade and the container walls.

This cork is supplied by the cork chain, made up of a team of volunteers, who mobilize to recover the corks, in order to recycle them into recycled cork aggregate, intended for the insulation of attics and floors.

Construction and exploitation costs

- 50 000,00 €

- 30 000 €

- 1 078 000 €

- 500 000 €

Reuse : same function or different function

- Structural works

- Structural framework

- Locksmithing-Metalwork

- Indoor joineries

- Outdoor joineries

- Floorings

- Partitions

- Isulation

- Suspended ceilings

- Electricity

- Heating ventilation air conditioning

- Plumbing

- Landscaping

- others...

- 1,200 reused sandstone cobblestones for the low wall on the periphery of the land (these are the old cobblestones that covered the quays)

- 8 reformed shipping containers of 20 feet

- 1 isothermal container of 40 feet

- 10.44 m3 of reused wooden joists

- 120.8 m² of structural floor

- Bricks: 3,200 m²

- Hessian bags: 94,400 m²

- Earth: 2.6 m3 (only for coatings)

- Box: 0.400 m3

- Marble powder: 0.190 m3

- Hair: 0.065 m3

- Sawdust: 1.560 m3

- Parchment of coffee: 0.390 m3

- Glazing: 8.82 m²

- Glued laminated worktops: 9.3 ml

- Suspended ceiling tiles: 158.7 m²

- 60 mm thick polystyrene panels: approx. 39.7 m²

- Structural floor (source: Linex 76)

- Reused joists (source: Garage 3R and Actis)

Environmental assessment

- water the green spaces, such as the greenhouse ;

- cleaning ;

- the realization coats earth ;

- toilet flushes.

Social economy

Reasons for participating in the competition(s)

Hangar Zero is a place dedicated to the circular economy. The work is carried out as much as possible with reused materials to serve as a pilot project. To reuse materials, we combine recycled materials (corks, paper, cardboard, plastic, etc.) and locally sourced and minimally processed organic/geo materials such as wood, straw and raw earth. We seek innovation in the use of these materials, in order to disseminate new low-tech practices.

Today, Hangar Zero opened a first phase of work, which will be followed by other phases, which will be delivered at the end of 2022 and all at the end of 2023.

Building candidate in the category