CHARACTERISATION OF RAW MATERIALS

Create a subpage- Sylvain Bosquet

- /

- the 10-07-2018

- / 2024

The SB&WRC project is supported by the European program Interreg VA France (Channel) England and receives financial support from the ERDF.

Introduction

At September 2017, ESITC Caen received 3 samples of unwashed waste from the University of Brighton: 2 x Polyester filling and 1 x Duck feather (Figure 1).

Figure 1. Photographs of waste used: (a) polyester filling (fabric), (b) polyester filling (balls), (c) duck feather.

A physical characterization of this waste has been carried out to determine:

- Bulk density;

- True density;

- Water content;

- Water absorption.

Experimental methods and results

1. Density

1.1. Bulk density

Bulk density was determined by using helium pycnometer (AccuPyc 1330_ micromeritics). This method allows to obtain a precise measure of the sample volume. It consists in introducing helium into a reference chamber with a known pressure and then it is allowed to expand into the chamber containing the sample. Thus, the drop in pressure is measured.

The sample volume is determined according to Mariotte law :

with :

- P1 : gas pressure in the reference chamber (Pa) ;

- P2 : gas pressure in the expansion chamber (which contains the sample) (Pa) ;

- Pa : atmospheric pressure (Pa) ;

- V2 : expansion volume (cm3) ;

- Vc : chamber volume (cm3) ;

- Vs : sample volume (cm3).

Bulk density is then given by the following equation :

with :

- ρb : bulk density ;

- ms : sample mass.

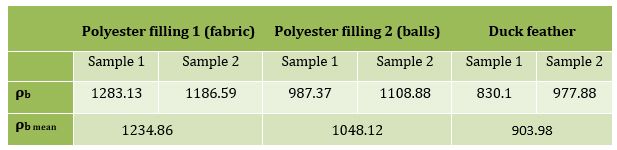

The results of bulk density are given in table 1. Two samples are tested per waste, and for each sample an average of 3 measurements is taken.

Table 1. Bulk density of the different waste [kg.m-3]

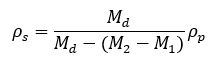

1.2. True density

True density is measured by means of a pycnometer with a countenance of 500 mL according to the procedure described below :

- Weigh the pycnometer filled with propanol to the mark:

- Weigh the pycnometer filled with saturated sample and propanol to the mark:

- Weigh the test sample in the dry state:

True density is then given by the following equation :

with

- ρp: propanol density.

Propanol was selected as an immersion liquid because it is characterised by a density which is lower than that of water thus enabling the feasibility and the execution of the test.

The results of true density are summarized in table 2.

Table 2. True density of the different waste [kg.m-3]

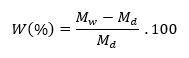

2. Water content

The test consists in drying the sample in a proofer at a temperature of 40 °C until the mass stabilizes. Water content corresponds to the registred loss of mass. It is calculated according to the following equation :

with :

- Mw : mass at the wet state ;

- Md : mass at the dried state.

The test was repeated three times for each material. The results of water content are given in table 3.

Table 3. Water content of the different waste [%]

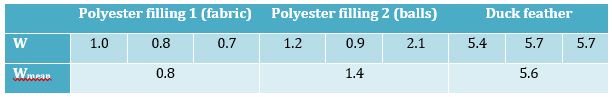

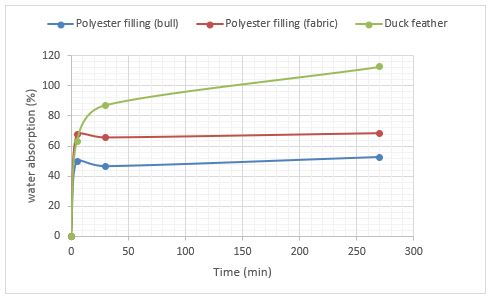

3. Water absorption

This test is derived from an experimental protocol developped by RILEM TC 236-BBM group. The procedure used to measure the water absorption of the different matreials is as follows :

- Dry the sample at 40 °C until a mass variation lower than 0.1% of is obtained in 24h;

- Immerse completely a plastic micro-perforated bag in water ;

- Place and attach the bag in a centrifuge and let it turn for 30 seconds at 500 trs.min-1, then note the bag mass ;

- Weigh a mass (M0) of the material and place it in the bag ;

- Immerse completely the bag filled with the material in water for 5 minutes ;

- Take the bag out of the water, place it in the centrifuge and let it turn for 30 seconds at 500 trs.min-1 ;

- Weigh the spin-dried bag and note the mass M1 (5 min);

- Repeat the steps 5, 6 and 7 for other samples for different immersion durations ;

- Calculate the water absorption according to the following equation :

The results of water absorption are given in figure 2.

Figure 2. Water absorption of raw materials

4. Conclusion

The physical analysis of these raw materials made it possible to have an idea about their properties and also about the possibility of using them as raw materials in the prototypes to be designed. Other raw materials should come from the University of Brighton to characterize them in turn.