First passive house in Brazil

Last modified by the author on 26/06/2019 - 16:45

New Construction

- Building Type : Isolated or semi-detached house

- Construction Year : 2017

- Delivery year : 2017

- Address 1 - street : BR - 59290-972 0000 SãO GONçALO DO AMARANTE (NORTHEAST), Brazil

- Climate zone : [As] Tropical dry

- Net Floor Area : 56 m2

- Construction/refurbishment cost : 68 000 €

- Number of Dwelling : 1 Dwelling

- Cost/m2 : 1214.29 €/m2

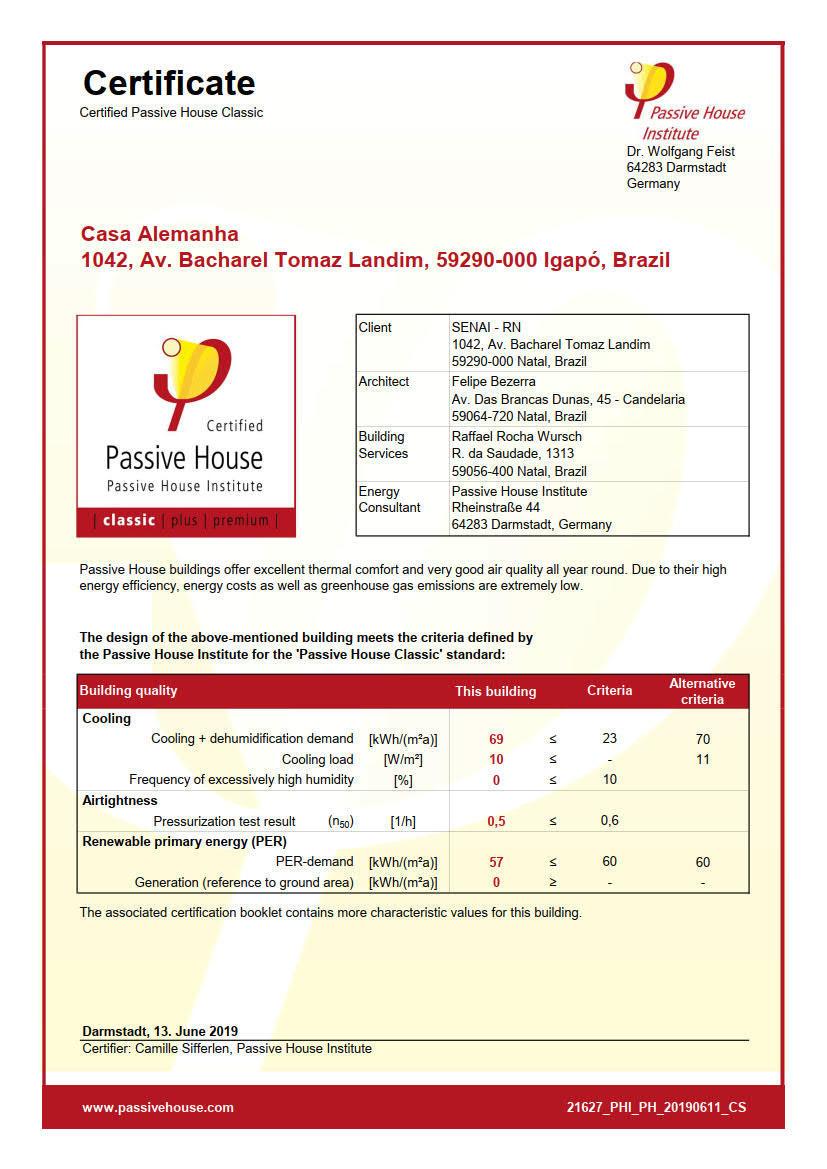

Certifications :

-

Primary energy need

113 kWhpe/m2.year

(Calculation method : Other )

We imported bricks from a company called LIAPAN, because these bricks can be produced in Brazil and they are not burnt as the ones we have on the market, which will help reducing the CO2 emission from brick companies.

The main focus is to improve Brazilian building standards construction to make people pay more attention to air quality, thermal comfort, energy spending, amongst others.

The house is located at SENAI, which is a school focused on developing construction labor (from Brick layers to Construction coordinators). This pilot project will be used to spread Passive House technologies: it will serve as a seminar room for hand labor, engineers, architects and anyone who is curious about it.

We also want to use this building to convince local manufacturers to produce the required high performance components. This will have a social impact, with the creation of new jobs and knowledge sharing.

In this project we also have an irrigation system (EcoRain – Germany) which can save up to 70% of water for grass irrigation, the whole system is automated. This system is way better than what we have available on our market because it avoids the over use of water because of evaporation, and also guarantees that every part is irrigated with the same amount of water (differently than the spliclers we have available).

See more details about this project

https://passivehouse-database.org/#d_5892Photo credit

Luiz Bezerra

Contractor

Construction Manager

Stakeholders

Designer

Felipe Bezerra Arquitetos - Brasil, Architekten Stein Hemmes Wirtz - Germany

Structures calculist

Joel Araujo

Certification company

Passive House Institute

Camille Sifferlen

https://passivehouse.com/Contracting method

Other methods

Energy consumption

- 113,00 kWhpe/m2.year

- 300,00 kWhpe/m2.year

Envelope performance

- 0,49

Systems

- No heating system

- No domestic hot water system

- Reversible heat pump

- Double flow heat exchanger

- No renewable energy systems

Urban environment

Product

LIAPLAN ULTRA 08

LIAPLAN STEINE

https://www.liaplan.de/Gros œuvre / Structure, maçonnerie, façade

Uv= 0.08 W/(mK) - Dimensions: 24,8 x 36,5 x 24,9

It's made out of clay and it's not burnt during its fabrication process.

We decided to use a material which can be produced in our regions (bricks made out of clay). For this house we imported all the bricks from Germany, but at the moment we are looking for manufacturers to start producing the bricks in Brazil.

Construction and exploitation costs

- 68 000 €

- 68 000 €

Water management

Comfort

GHG emissions

- 23,20 KgCO2/m2/year

Reasons for participating in the competition(s)

The house is located at SENAI, which is a school focused on developing construction labor (from Brick layers to Construction coordinators). This pilot project will be used to spread Passive House technologies: it will serve as a seminar room for hand labor, engineers, architects and anyone who is curious about it.We also want to use this building to convince local manufacturers to produce the required high performance components. This will have a social impact, with teh creation of new jobs and knowledge sharing.

Building candidate in the category

Energy & Hot Climates

Low Carbon

Health & Comfort