Mohammed VI International University Hospital

Last modified by the author on 23/03/2021 - 13:02

New Construction

- Building Type : Public or private hospital

- Construction Year : 2017

- Delivery year : 2020

- Address 1 - street : P3011, Bouskoura 27182, Maroc 27182 CASABLANCA, Maroc

- Climate zone : [Dfa] Humid Continental Hot Summer, Wet All Year

- Net Floor Area : 47 000 m2

- Construction/refurbishment cost : 67 000 000 €

- Number of Bed : 325 Bed

- Cost/m2 : 1425.53 €/m2

Certifications :

-

Primary energy need

665 kWhep/m2.an

(Calculation method : RTCM )

The Mohammed VI International University Hospital is a large-scale state-of-the-art project dedicated to scientific research and teaching of medicine. Extending over a covered area of 47,000m2, it has a total capacity of 325 beds, 28 consultation rooms, 15 exploration and treatment rooms and 11 operating theaters on a technical platform that meets international standards. The poles of excellence which make this hospital a benchmark establishment are the Mother-Child pole, the Trauma-Center, the Head and Neck pole. The hospital offers its patients a care space that combines efficiency with pleasure, and its teams a work environment conducive to development and continuous improvement.

Data reliability

3rd part certified

Photo credit

not

Contractor

Construction Manager

Stakeholders

Contractor

FONDATION CHEIKH KHALIFA IBN ZAÏD

Assistance to the Contracting Authority

JESA

Assistance to the Contracting Authority

ELAN CERTIFICATION HQE

Other consultancy agency

INGEROP FRANCE

Contracting method

General Contractor

Owner approach of sustainability

BYMARO in agreement with the contracting authority wished to include the construction project of the University Hospital of BOUSKOURA in a sustainable development approach through the realization of a project that respects the environment, consumes little energy and offers a pleasant living environment for patients, their families and staff. The following environmental objectives have thus been set:

- Optimization of access to the site

- Limiting the overall energy consumption of buildings

- Water management on the site

- The attractiveness of open spaces and gardens

- Good waste management

- Comfort for patients, staff and visitors

- Good acoustic management between the different premises

- The assurance of a balanced, equitable, progressive and environmentally friendly development, both during the execution of the works and during the use and maintenance of the buildings.

BYMARO wanted to strengthen the anchoring of this operation in Sustainable Development, by proposing a project integrating all the environmental, economic and societal aspects required for the hospital of tomorrow.

In order to guarantee the achievement of its objectives, BYMARO has secured the services of a multidisciplinary team and a Sustainable Construction Project Owner. A Project Environmental Management system has been put in place to define the technical and human organization necessary to maintain the sustainable quality of the project.

Architectural description

See description in the attached note

If you had to do it again?

Yes, it's a great experience to do again

Energy consumption

- 665,00 kWhep/m2.an

- 838,00 kWhep/m2.an

- 259,00 kWhef/m2.an

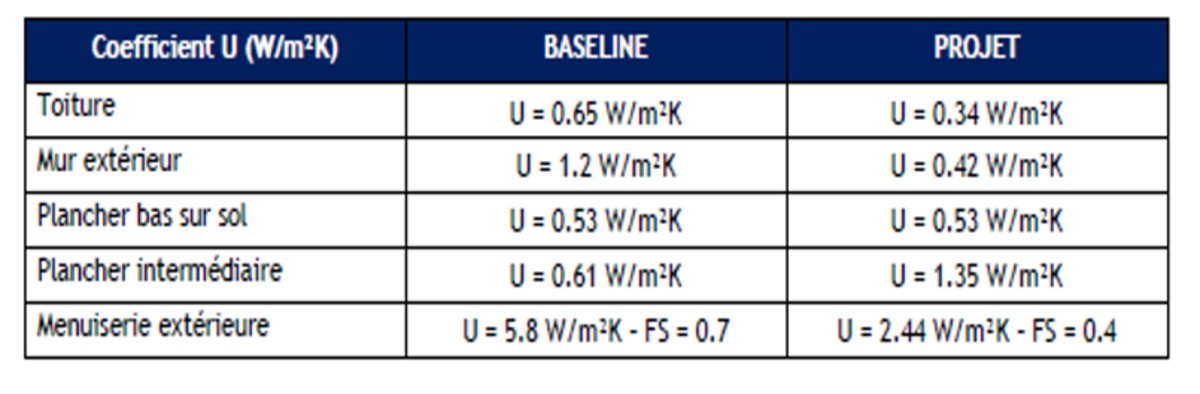

Envelope performance

- 1,20

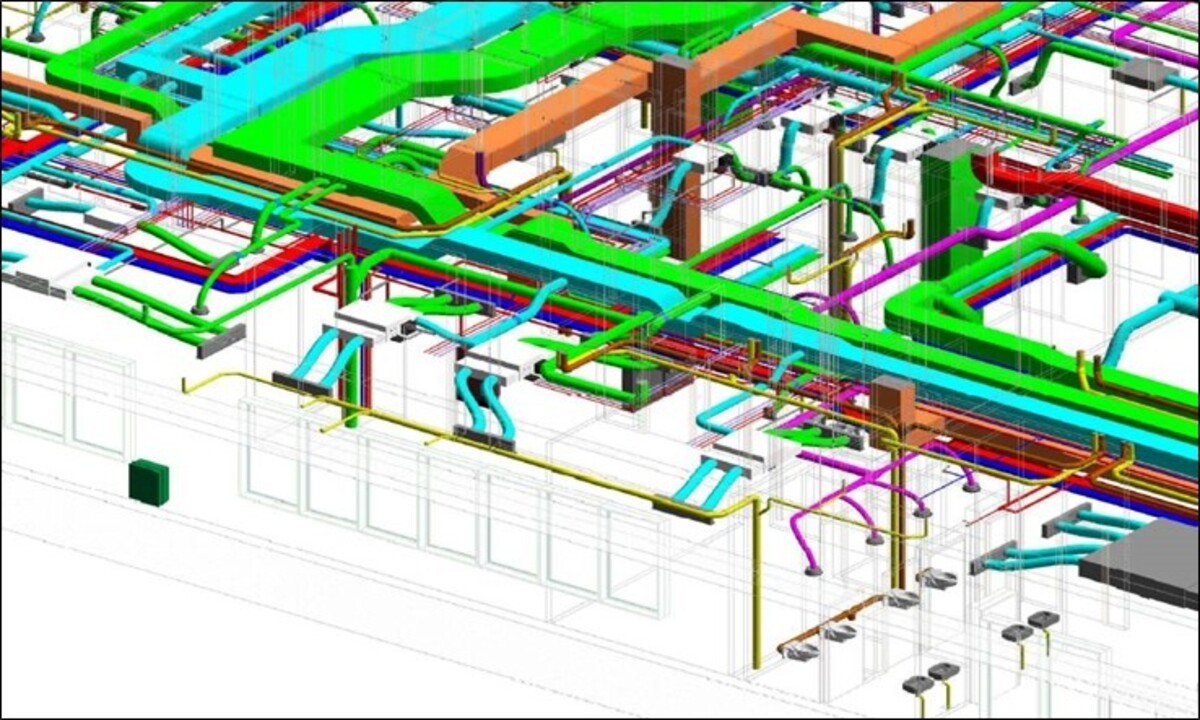

Systems

- Boiler fuel

- Fan coil

- VAV System

- Boiler fuel

- Other hot water system

- Water chiller

- Fan coil

- VAV Syst. (Variable Air Volume system)

- Radiant ceiling

- Natural ventilation

- compensated Air Handling Unit

- Double flow heat exchanger

- Other, specify

Smart Building

Water management

Indoor Air quality

Comfort

Construction and exploitation costs

- 2 000 000 €

Building Environmental Quality

- Building flexibility

- indoor air quality and health

- biodiversity

- works (including waste management)

- acoustics

- comfort (visual, olfactive, thermal)

- waste management (related to activity)

- water management

- energy efficiency

- maintenance

- products and materials

Reasons for participating in the competition(s)

Energy saving compared to the reference building of 21%

Important acoustic performance

Expertise in lean management and BIM model.

1st HQE certified project at Very good level internationally: Pilot Project

Building candidate in the category

Energie & Climats Chauds