Rockcycle Recycling Service

Last modified by the author on 29/05/2019 - 17:03

- Year of commitment : 2018

- Address 1 - street : 46, RUE DU COMMANDANT BOUCHET, MEUDON LA FORêT, France

- Diameter : 27000

- Circular economy and waste management : Services & Organization, Industrial Ecology, Reuse, Optimization of ressources

-

7 200 €

Rockcycle Recycling Service

Rockcycle is a site waste recycling service. It allows any company using ROCKWOOL products to combine productivity and ecology. This sustainable development approach is an economic innovation and easy to implement. Concrete example: the rehabilitation of a residence in Meudon

This new service was tested during an insulation project in Meudon. JCP Enterprise has used Rockcycle as part of the rehabilitation of a residence of 556 homes. 27,000 m2 of insulating materials were laid. The company wanted to fight against the pollution related to the incineration or the burial of the waste. The installation teams easily assimilated the sorting rules provided by ROCKWOOL: filling big bags, stacking wooden pallets.

Sustainable development and the circular economy: all mobilized

Rockcycle is a service for the recovery and treatment of waste from ROCKWOOL products.

Why is recycling important in the construction sector? The construction sector produces one third of all waste; most of it completes its life cycle in a landfill. Site waste is a potential source of raw materials for recovery. To prevent its construction products from becoming waste, ROCKWOOL encourages recycling through a dedicated service. Sorting and recycling are key actions to limit carbon footprint and green growth.

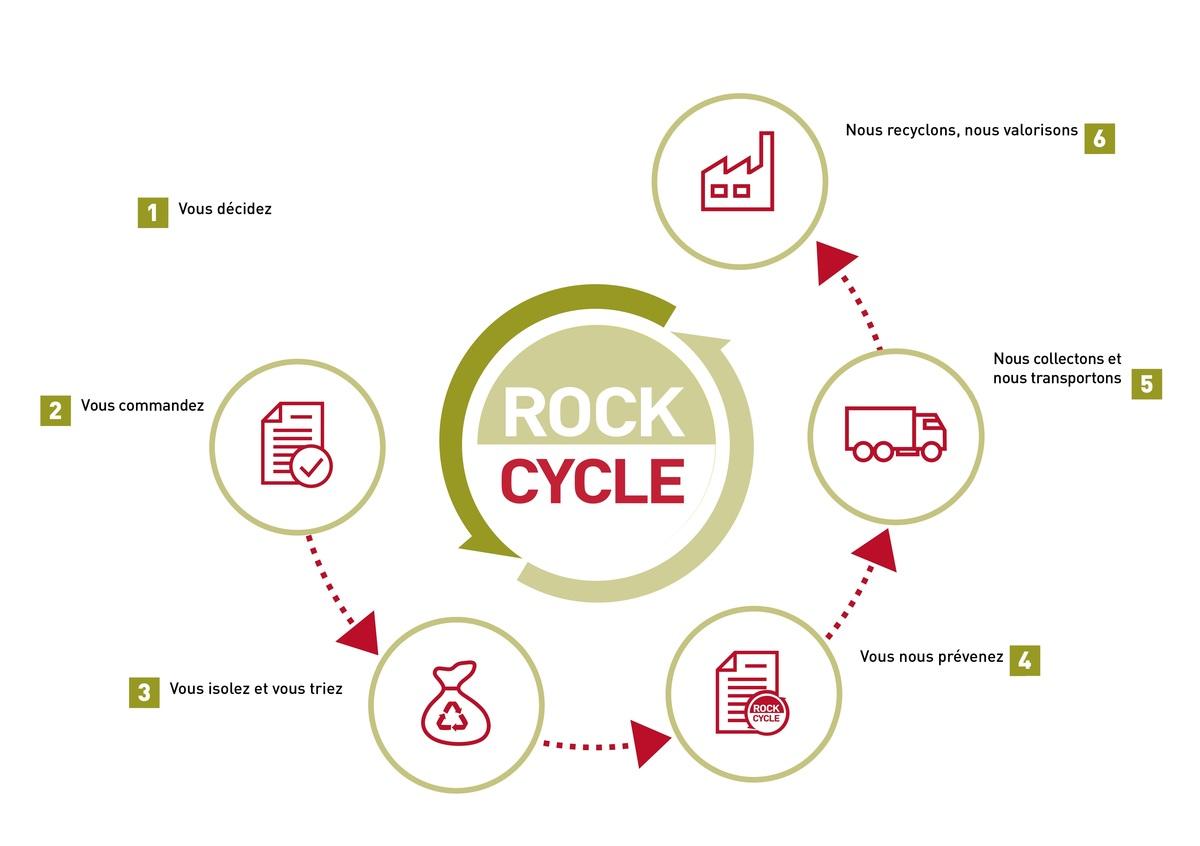

How to recycle with Rockcycle?

All waste from ROCKWOOL products is recovered : rockwool waste , packaging plastics and wooden pallets. Much more than a second life is granted to them.

Rockcycle thus enables as many people as possible to contribute to a more sustainable way of life and production .

Progress Status

In progress

Data Reliability

Self-declared

Funding Type

Private

Website Enterprise / Infrastructure

https://www.rockwool.fr/outils-et-services/services/rockcycleSustainable Development

- The project holder has an essential role: it is up to it to ask the company of works to valorize the waste resulting from the building site.

- The construction company then chooses a supplier of insulating panels that takes ecological issues into account through a recycling service.

- At the beginning of the project, the installation teams receive clear instructions in order to efficiently sort the waste generated by the site.

Testimony / Feedback

Olivier Enes, Chief Operating Officer at JCP Entreprise , in charge of the work of the residence in Meudon, testifies:

"Semi-trailers come, and we deliver in large quantities. Employees sort and recover waste. When we have enough filled big bags, we call ROCKWOOL, who brings in a truck, and picks up big bags to retreat. " "Whether we put rockwool in skips, or big bags, it's pretty much the same thing. The advantage is that we know where the waste goes, and how it is processed. We are really in the ecological approach . I think that today's and tomorrow's jobsites should be treated this way. " Michel Soria, ROCKWOOL Metallic Envelope Product Manager , explains the different stages of the service:"We are fortunate to have a geosourced insulation that is infinitely recyclable. Today, waste is also reused in the manufacturing process. We wanted to go further: recover the waste generated by construction sites.

The cycle is pretty simple: when you have a facade or waterproofing site, you have a rockwool order, and you can take the ROCKCYCLE option. By filling in your order and the ROCKCYCLE form, you specify that you want to benefit from this recycling service. It is a turnkey service for our customers. The only effort they have to make is to warn and sensitize their team to do the waste sorting.

We are happy today to expand our program. On this site we are in areas much more urban and dense. It was necessary to adapt our type of transport to pick up the waste generated by these sites, with smaller trucks. We are now offering this offer to all sites in France. "

Governance

ROCKWOOL France

Private Company

Construction Industry

Public

The ROCKCYCLE tariff for Façade worksites is: € 144 per truck, ie € 25 / m3.

For comparison, waste treatment for a 10 m3 landfill is 380 €, or 38 € / m3.

With ROCKCYCLE, recycling waste is cheaper than burying it. There is no minimum of recovery.

Sustainable Solutions

- Resources :

- Circular economy

- Waste management

Rockcycle Facade

Problem: How to carry out an isolation project in a productive and ecological way ?

Solution: Rockcycle processes all waste from ROCKWOOL insulating materials.

Beyond the recyclable plastic packaging and pallets repaired, it is the rock wool that allows to be the most circular.

Rock is one of the most abundant commodities on the planet, but we must continue to make better use of our planet's resources. This material can be recycled to infinity in a new rockwool. It is directly reintegrated into the production process in the ROCKWOOL Auvergne factory. It is an important element of a "circular" economic model and a way to move towards a more sustainable way of life and production.

In 2017, ROCKWOOL collected approximately 120,000 tonnes of used rock wool for reuse and recycling.

This innovation is easy to implement, everywhere in France, the site is located in urban or rural area.

Reasons for participating in the competition(s)

Rockcycle, en bref :

- Développement durable et économie circulaire : le service réutilise 100% des déchets, sans diminuer la productivité.

- Avantage économique : faire un geste pour la planète coûte moins cher que ne pas recycler.

- Facilité de mise en oeuvre : des fiches de consignes de tri sont disponibles sur le site ; un partenaire Rockwool est toujours joignable en cas de besoin.

Building candidate in the category

Sustainable Infrastructure Grand Prize