Pierre Mauroy Stadium

Last modified by the author on 16/06/2017 - 17:48

- Year of commitment : 2012

- Address 1 - street : 261 BOULEVARD DE TOURNAI - 59650 VILLENEUVE-D'ASCQ, France

- CO2 Impact : The event consumptions are virtually decarbonised thanks to the securing of stadium power supply by high-capacity dynamic inverters capable of compensating for the interruption of the ENDIS electrical network

- Biodiversity & Ecosystems : / Ecosystems preservation /

-

324 000 000 €

- Builder

Eiffage

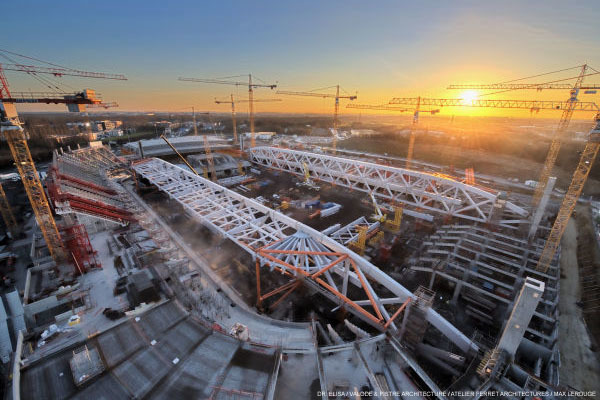

The arena of the 21st century: located on the so-called "Borne de l'Espoir" site, on the communes of Villeneuve d'Ascq and Lezennes (North), the Pierre Mauroy Stadium is an exceptional work. It combines, in the same place, a stadium and a real arena. It includes two major innovations: a mobile roof and a mobile lawn unique in the world, allowing it to be transformed into the largest arena in Europe in less than 24 hours to accommodate the largest sporting events as well as cultural events of national and international scope.

Progress Status

Delivered

Data Reliability

Self-declared

Funding Type

Public/Private Partnership

Website Enterprise / Infrastructure

http://www.eiffage.com/projets-acheves/stade-pierre-mauroySustainable Development

- Two mega-beams with a span of 205 m and 17 m high support the structure, they are equipped with prestressing cables, these pre-stressed metal beams represent a world first. They avoid any visual discomfort to the spectators allowing a 360 ° vision.

- The roof can be closed in less than 30 minutes and has a three-fold function: protection against bad weather, total obscuration of the interior of the Stadium and reduction of the noise level vis-à-vis the outside, especially during concerts.

- An approach to air effects was carried out on a model to measure comfort in the forecourt and the stands.

- The translucent envelope represents the boundary between the public area and the interior of the Stadium. Unlike most stadiums there is no roasting, which has made it possible to avoid the creation of neutral spaces, unoccupied and unsafe between accesses and ambulatory.

- The Stadium is designed to accommodate all audiences and especially disabled people with adapted access and dedicated spaces throughout the stadium.

- In the construction phase, the insertion of people far from the job was achieved thanks to the deployment of EIFFAGE tutors and mentors experienced in insertion.

- In addition, the companies welcomed apprentices and trainees of all levels, from the worker to the engineer. Subjects of final work for teams of engineer students from local schools have also been proposed.

- Guided tours of the works and a welcoming pavilion open to the public made it possible to discover the project, with a great success (between 800 and 1,000 visits every Sunday).

- The site had an area of potentially polluted soil. Its resorption was framed by an authorization to operate an installation classified under the vigilant control of the administration. Information commissions for local residents were provided.

- Access to the Stadium favors soft travel modes and the use of public transport, especially the two metro lines. Pedestrian paths, bike paths and bus corridors have been created to reach the site.

- Volunteer establishment of a bats shelter: it was designed to avoid the risk of destruction of potential habitats of the two protected species found during the filling of quarries during the construction of the Stadium. These include common pipistrelle (Pipistrellus pipistrellus) and Natterer's vespertilions (Myotis nattereri), respectively classified as a minor and vulnerable concern on the IUCN Red List. The site specially reserved for breeding (farrowing and breeding) is located above a boiler room located under the forecourt, accessible only to authorized persons.

- Selective waste sorting in the site.

- Ecocup system during events (eco-friendly reusable cups).

- Implementation of an insulation of the heated premises superior to the contractual requirements.

- Recuperator of energy on fumes.

- Variable flow air handling units (blowing and recovery) equipped with frequency inverters and equipped with a variable-speed energy recovery wheel with a yield of 68%.

- Installation of dynamic inverters on critical audio-visual functions to restrict the use of fuel-intensive generators.

- Development of a centralized technical management solution enabling zone lighting and heating to be controlled according to occupancy scenarios.

- Recovery of rain water for toilets, lawn watering and fire protection.

Testimony / Feedback

- Côté Stade

- Dossier de presse

- Article de la Voix d Nord (21/4/10)

Governance

- ELISA (EIFFAGE Lille Stadium Aréna) on behalf of Métropole Européenne de Lille

- EIFFAGE (all its business lines participated: Infrastructure, Metal, Construction, Energy and Concession)

- Groupement of architects: Valode & Pistre and Atelier Ferret Architectures

ELISA (EIFFAGE Lille Stadium Aréna) on behalf of Métropole Européenne de Lille

Private Company

Eiffage

Construction Industry

Private

31 years of initial concession: monthly rent paid by the community + recipes of events organized by the operator + additional events beyond the number of scheduled meetings scheduled for the resident club

Sustainable Solutions

- Low-carbon materials/ infrastructure

Dynamic inverters

Traditionally, stadiums use the reverse system. That is to say, generating sets operate during matches and the ENEDIS network is used in case of breakdown of these groups. At the Pierre Mauroy Stadium, reverse operation was adopted. The enclosure operates on the network, being located in an urban area.

In the event of a breakdown of the traditional network, 2 dynamic inverters of 625 kVA each take up the load, useful for the continuity of the event, waiting for the start of the 3 generating sets of 800 kVA. The dynamic inverters ensure continuity for one minute, thanks to very large inertia magnetic flywheels driven by the electrical current of the network, which accumulate sufficient inertia in the event of a power outage or disconnection of the network. In this way, they can continue to produce electricity without interruption for high-consumption sensitive equipment such as field lighting, media and TV cabinets, giant screens, the time that diesel emergency generators take over the network.

This solution respects the environment because, unlike most other stages, generating sets, which are large fuel consumers and CO2 emitters, are only started very exceptionally in the event of an ENEDIS network outage. Until 2016, it would have required 42,730 liters of diesel to meet the electricity requirements during the football matches, which reduced 111100 kg of CO2 for unused fuel.

- Non-renewable energy economy

- Reduction of greenhouse gas emissions

- Improved worker comfort and safety during implementation

- Reduction of nuisances for local residents

- Low-carbon materials/ infrastructure

Low-temperature asphalt (EBT®)

The internal service path allowing to circulate under the steps is composed of a layer of low temperature asphalt. EBT® are a less energy-consuming alternative to hot mix as they contribute to the development of environmentally friendly processes. Their high durability ensures low maintenance costs, saving natural resources and reducing overall costs over the long term. The manufacture of EBT® is carried out using either a bitumen-specific additivity or a bitumen foaming technique. The final temperature of the mix at the outlet of the mixer is about 30 ° C. lower than that of the conventional mixes using the same binder, ie approximately at 130 ° C. For hard or modified bitumen asphalt formulas or containing recycled, the temperature drop is adapted. The constituents and the means of implementation are identical to those of hot mix asphalt. The strengths of EBT®:

Reasons for participating in the competition(s)

Sa multifonctionnalité et les technologies mises en œuvre en font un équipement sportif et culturel unique en son genre, véritable bijou technologique internationalement reconnu, comportant les atouts suivants :- Une méga structure au service de la multifonctionnalité

- Modularité et usage intensifié

- Un modèle d'intégration dans l'économie et le tissu social local

- Une opération d'aménagement urbain

Building candidate in the category

Users' Choice

Sustainable Infrastructure Grand Prize

Christophe Buhot

Responsable Pôle activités infrastructures - Direction Développement Durable Innovation Transverse