The Silhac Hut

Last modified by the author on 23/05/2022 - 10:26

New Construction

- Building Type : Isolated or semi-detached house

- Construction Year : 2018

- Delivery year : 2020

- Address 1 - street : 553 route du Chiat 07240 SILHAC, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 66 m2

- Construction/refurbishment cost : 68 619 €

- Number of Dwelling : 1 Dwelling

- Cost/m2 : 1039.68 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : )

This project won the Grand Prize in the "Residential buildings / new construction" category of the 2022 Circular Buildings Trophies.

La Cabane de Silhac is a tiny house whose history is intimately linked to the designer and resident that I am, Célia Auzou.

In 2016, after 8 years of rather conventional architectural practice in an agency, I am bored and I am quite frustrated by the lack of practice and conviction that I encounter around my profession. I then decided to carry out a personal project allowing me to simultaneously achieve several objectives: to live in a "refuge" place in nature, to fully experience a construction site, to self-build, to confront my ideas of eco-responsibility with reality, to implement work and have reuse materials implemented .

To do this, after many sketches, I produced a project that conquers me. The house envisaged is very compact since it is a simple, parallelepipedic volume, of 36m² of living space. In order to deceive this reduced surface, the height under crawling is 3m on average and the surface of the living room reaches 27m². To manage the steep slope of the land (welcome to Ardèche) and find a place for DIY and storage, the house has a workshop under its living space. The 36m² and their terrace are therefore suspended above the surrounding forest. At this stage, the main lines are drawn.

The desire to work with reused materials implies adapting to what is already there. The small size of the house, already frugal in itself, facilitates the integration of these materials . Thus, the exterior joinery, the interior joinery, the electrical equipment, the terrace, the wall and ceiling covering, the frameworks of the partitions and the joists, the stove, the sanitary elements, the furniture and the household appliances, the layout of the exteriors are all subjects made for reuse. 14 tons of materials are reused on the micro-house and in its outdoor facilities.

If you had to do it again?

Having now the adequate local network, I would consider finding reused wood for the frame, thus greatly reducing the impact of the building and pushing the experiment further. Other items such as insulation and wood cladding on the facades would also be sourced for reuse. On the design side, I don't think anything would be changed. Perhaps, the 20cm wider building for a little more space in the kitchen and on the side of the bed in the bedroom.

See more details about this project

http://www.ville-amenagement-durable.org/IMG/pdf/fiche_rex_reemploi-silhac_la-cabane.pdfPhoto credit

Celia Auzou

Contractor

Construction Manager

Stakeholders

Company

TECHNOBOIS

François-Pierre MOURGUES

http://techno.bois.free.fr/Charpentier

Company

FERRONERIE MARTEL

Romuald MARTEL

Ironworker

Company

Minéka

Joanne BOACHON

https://mineka.fr/Supplier of recycled materials

Assistance to the Contracting Authority

Re.Source Réemploi

Célia Auzou

https://resource-reemploi.fr/AMO reuse

Type of market

Global performance contract

Real final energy consumption

3 984,00 kWhef/m2.an

110,00 kWhef/m2.an

2 021

More information

There has never been an Energy Audit of the building or DPE.

Systems

- Wood boiler

- Individual electric boiler

- No cooling system

- Single flow

- No renewable energy systems

Urban environment

- 2 000,00 m2

- 40,00 %

Product

Dismantling

Des gens plein de bon sens

-

https://www.bazed.fr/

Demountability in architecture concerns the ability of a building, a construction system, an assembly to be demountable, suitable for deconstruction.

An ideal demountable building is characterized by the possibility of being taken apart and reassembled or reused over and over again.

Rational Living Area

D’autres gens plein de bon sens

-

http://ido.archi/

Construction and exploitation costs

- 68 619 €

Reuse : same function or different function

- Indoor joineries

- Outdoor joineries

- Partitions

- Electricity

- Landscaping

- others...

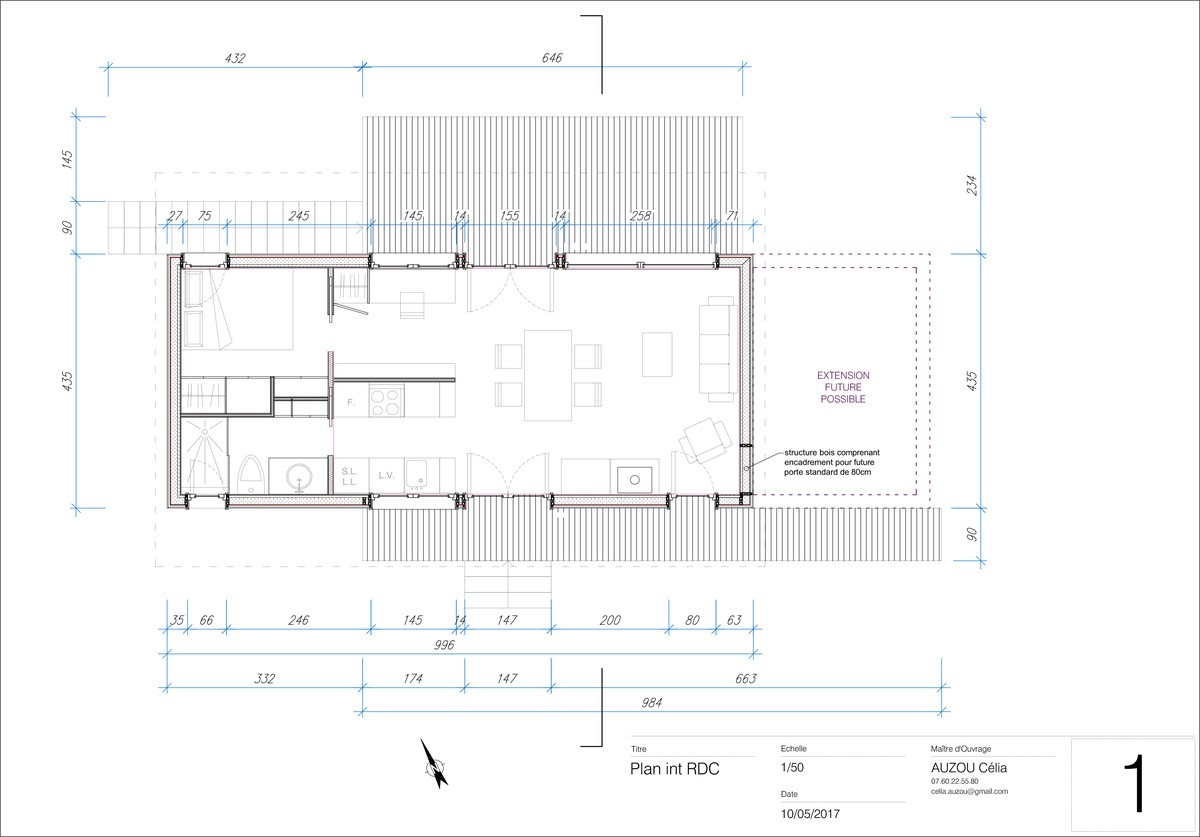

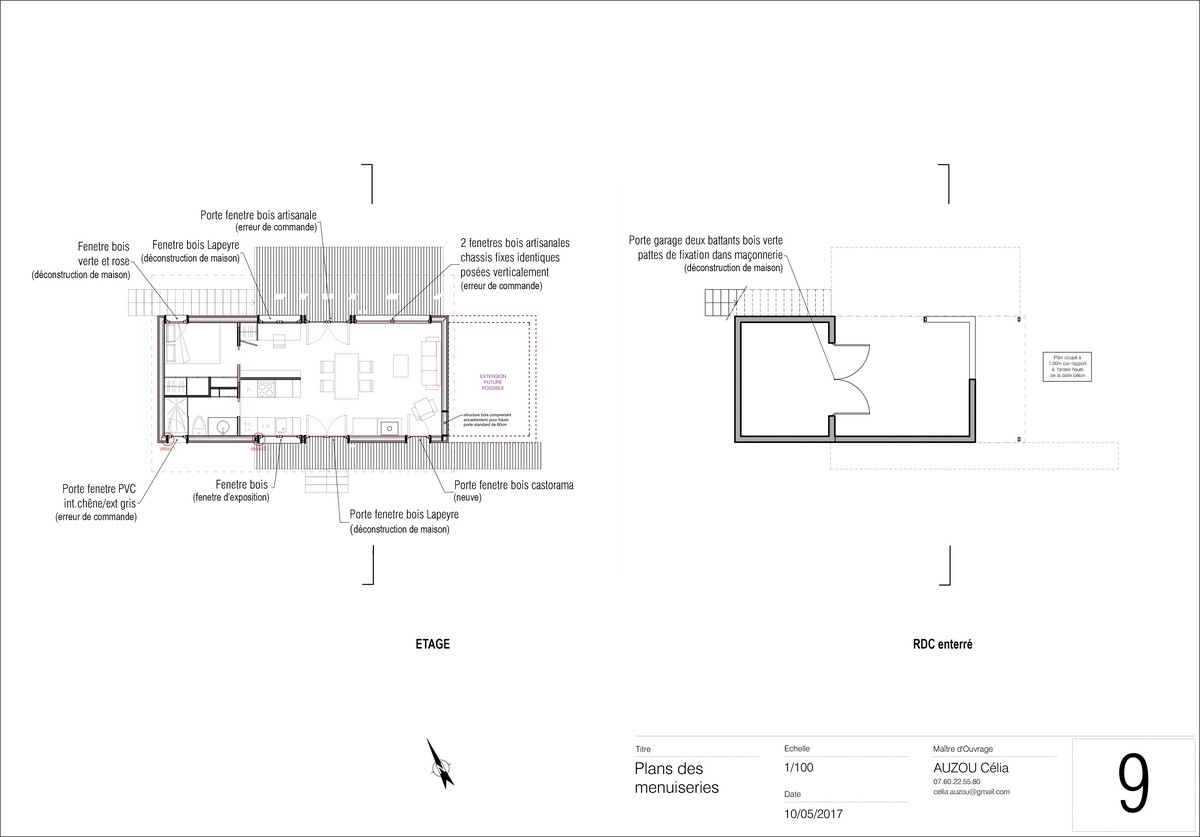

- 10 exterior joinery including 9 second-hand resulting from careful dismantling, order errors and exhibits (see plan of joinery). Lot 2680€ transport included (+1350€ installation in total);

- the interior carpentry : for example the two kitchen worktops made of two medium slabs recovered from a material library, as well as the second-hand tiling that covers them, or the washbasin in the shower room made of trespa (fall facade and therefore waterproof) + vanity unit based on an old chest of drawers. We can also mention skirting boards from a construction surplus (40ml). Batch 190€ transport included;

- electrical equipment, i.e. all switches, sockets and light fixtures. Batch 10€ transport included;

- the terrace , more specifically the wooden slats up to 40m² collected (via le bon coin), cleaned, cut and turned over to be reworked for 32m², to the south and north. Batch 150€ transport included;

- the wall and ceiling covering comes from the 2017 architecture biennial (Atelier Utopies) which took place at the Sucrière in Lyon. The implementation of the scenography having been considered upstream as "non-destructive", the planks and wooden cleats were tied by rope. Thus, they were virgin and suitable for reuse. They are 100u in number. of pine panels (2000 mm x 500 mm x 18 mm thick) and cover all the peripheral walls of the house as well as the ceilings of the 3 rooms. In order to limit falls, the layout has been made according to their size, drastically limiting falls. Batch 350€ transport included;

- the frameworks of the partitions and the joists are from the same sourcing as the pine panels. They are 85u in number. of pine cleats (32 mm x 45 mm x 4500 mm). They receive the panels of the walls, the ceilings and the solid parquet floor, while offering the adequate technical space for the passage of the networks. Batch 400€ transport included;

- the stove and its floor plate , acquired second-hand in the village of Silhac, from an acquaintance. I acquired the smallest that I found used (by an acquaintance) so as not to over-consume. It is 4kw and I spend a cubic meter of wood per year (my neighbor cuts it, dries it then cuts it for me) to heat the volume during the cold period. Batch 330€ including transport (+1500€ of installation in total with supply conduit and exit in roof);

- the sanitary elements , which are the washbasin, the kitchen sink, the fittings from private individuals Le Bon Coin. Batch 110€ transport included;

- the ventilation grilles / air inlets from a private Le Bon Coin. Batch 30€ transport included;

- the paint on the walls comes from the bottoms of pots of professional painters. Batch 10€ transport included;

- furniture and household appliances , in their entirety (sofa, desk, chairs, tables, bed, oven, fridge, hotplates, dishwasher, etc.) from private individuals at Le Bon Coin. Batch 2600€ transport included;

- the development of the exteriors , in particular the exterior staircase in mixed technique: high steps in chestnut beams from the deconstruction of an inn in the neighboring village and low steps in stones from the land, from fallen dry stone walls. The already-there takes on its full meaning. We can add the work currently in progress which is a wooden fence in bastaings resulting from a deconstruction site of a French-style wooden slab and the installation of 3 water recovery tanks (1000L each). Batch 200€ transport included;

Environmental assessment

- the stove and its floor plate;

- elements complementary to external work (screws, ropes, etc.)

- some furniture such as the dresser in the shower room, the bed, the sofa and all the other small pieces of furniture / decorative elements in the cabin;

| Outdoor Facilities | 2840.214264 | 31.81952695 | 6441.51221 |

| Landscaping / Locksmithing - Metalwork | 0 | 0 | 0 |

| framework | 1161.906667 | 18.58066 | 1008.333562 |

| Partitions | 0 | 0 | 0 |

| 0 | 0 | 0 | |

| Roofing / Outdoor facilities | 0 | 0 | 0 |

| Lightings | 671.7746124 | 4.419368699 | 719.2832713 |

| Security lights | 0 | 0 | 0 |

| Engineering equipment | 0 | 0 | 0 |

| Electrical equipment | 20.72221888 | 1.270485753 | 32.06175904 |

| facades | 0 | 0 | 0 |

| False ceilings | 0 | 0 | 0 |

| Raised floors | 0 | 0 | |

| False ceilings | 1282.759658 | 19.96520344 | 1899.93657 |

| Big work | 0 | 0 | 0 |

| Sanitation facilities | 196.3616837 | 1.79894275 | 144.7462377 |

| Insulation | 0 | 0 | |

| Exterior carpentry | 1436.725045 | 13.95544533 | 1524.253577 |

| Interior joinery | 169.335 | 4.227245667 | 454.1590882 |

| Furniture | 1696.350985 | 638.8669183 | 1437.140234 |

| Paint | 16.74170246 | 0.446296335 | |

| Plumbing | 74.85 | 1.01805 | 199.9663638 |

| floor coverings | 47.56106948 | 10.1588978 | 98.0695322 |

| Floor or wall coverings | 0 | 0 | 0 |

| Wall coverings | 0 | 0 | 0 |

| 0 | 0 | 0 | |

| Locksmithing - metalwork | 49.98493717 | 0.619533229 | 32.94360732 |

| VRD | 0 | 0 | 0 |

| CO2 avoided (kg) | Water consumption avoided (m3) | Waste avoided(kg) | |

| TOTAL | 9665.287843 | 747.1465743 | 14008.25989 |

The reuse operation saved the equivalent of 77,322 kilometers traveled by a small car, i.e. 88 Paris-Nice journeys, 4,981 rectangular bathtubs filled with water and 28 years of household waste for a Frenchman

In the calculation of avoided impacts, I was not able to take into account:

And I counted the 100m² of interior wooden wall and ceiling panels in the category of reconstituted wooden false ceiling (in the absence of another more suitable category). Also, I counted the 85u of cleats and the 40ml of pinths under the wood frame category (in the absence of another more suitable category there too).

Economic assessment

- 7 056 €

- 10 %