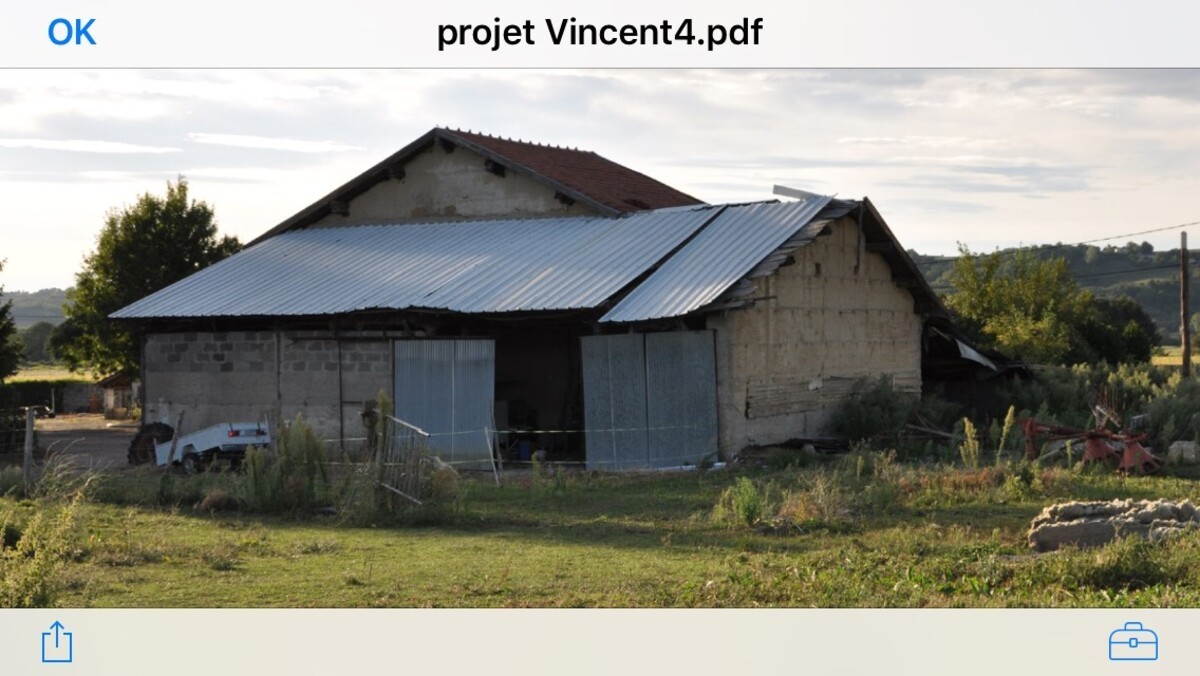

Rehabilitation of an old barn into a detached house

Last modified by the author on 17/03/2021 - 18:17

Renovation

- Building Type : Isolated or semi-detached house

- Construction Year : 1940

- Delivery year : 2017

- Address 1 - street : 4303 route de viallière 38780 SEPTEME, France

- Climate zone : [Dwa] Humid Continental Hot Summer, severe, dry winter

- Net Floor Area : 196 m2

- Construction/refurbishment cost : 230 000 €

- Number of Dwelling : 5 Dwelling

- Cost/m2 : 1173.47 €/m2

-

Primary energy need

52 kWhep/m2.an

(Calculation method : RT 2012 )

It is an old adobe barn dating from 1940 that has been transformed and rehabilitated into a contemporary living house.

The choice of biosourced materials...

This house benefits from a biosourced facade coating made of lime and hemp. Acting as an insulator, this coating contributes to the building's inertia, which limits the impact of outside temperature variations on the building's interior temperature, and thus improves the occupants' comfort.

Thanks to this solution, the house benefits from an excellent summer comfort. The high thermal effusivity of the product used is 156 J/K.m2.s1/2. This provides a good thermal phase shift: 4H20 of additional inertia to that of the adobe wall, for a thickness of 8 cm of coating.

The house also benefits from a winter comfort. The thermal conductivity of the product is λ = 0.066 W/m.K (at 23 ° C and 50% of H.R)

Key to the renovation of this type of building the transfer of water vapor is optimized: water vapor permeability of the product μ = 4.2, very low for a better breathability and a limitation of condensation in the walls.

This creates the conditions for a healthier environment limiting the development of mold and dust mites.

Finally, thanks to this solution, the house benefits from a significant acoustic comfort. The solution shows acoustic performance by transmission loss: 53 dB for 5 cm thickness.

In addition, the interior walls of the house were coated with a lime-based solution that provides the building with a healthier, VOC-free interior environment.

Testimonials

"We wanted to create a healthy, warm and modern house, respecting the old building.

We wanted to use natural materials and to have a balance between the old and the new, both through the architecture of the building and the materials used.

We therefore kept the adobe walls and did a lot of masonry work to enlarge the existing openings and create new ones to bring light into the house. We also enhanced an old window discovered during the work, which is now an interior niche whose molasse contours recall the charm of the old.

In order to capitalize on the breathing properties and the inertia of the adobe while ensuring a good insulation of the house, we have favored a lime / hemp coating on the outside, PARNATUR Corps d'Enduit Chanvre from PAREXLANKO.

For the interior, again, we wanted to use a natural coating and we chose a lime coating (PARLUMIERE CLAIR by PAREXLANKO).

Inside and outside we have given an important place to wood in order to bring warmth (parquet, doors, wooden terrace...), and we have also integrated steel to bring a modernity to the whole (structure of the staircase, visible IPN above the windows, footbridge with IPN...).

The whole constitutes a harmonious alliance old/modern, respectful of the charm of the old building highlighted through the choice of noble and natural materials."

Sustainable development approach of the project owner

OBJECTIVE: to preserve the properties of rammed earth (inertia and perspiration) but also the spirit of this old building, thanks to the choice of natural and warm materials. Combine the authenticity of the old with the modern by using the most natural products possible.

Architectural description

Rather classic rural pavilion with modern facades with large glazed openings to bring in light.

Building users opinion

It is a house in which you feel good, bathed in natural light with large living spaces. Thermal comfort regulated in summer as in winter by the inertia of the adobe walls coated with PARNATUR Corps d'Enduit Chanvre.

Photo credit

Vincent Drevon

Contractor

Construction Manager

Stakeholders

Environmental consultancy

Entreprise LCF LAZ CREATEUR DE FACADE ELMAS CELAL

Environmental consultancy

Entreprise PIERROT PLOMBIER

Environmental consultancy

Entreprise PATRICK POIPY ELECTRICITE

Energy consumption

- 52,00 kWhep/m2.an

- 100,00 kWhep/m2.an

- 150,00 kWhep/m2.an

Real final energy consumption

10 330,00 kWhef/m2.an

Envelope performance

More information

2018: 12,792 kwh 2019: 15,064 kwh Exterior plastering work carried out in June 2019-2020: 10,330 kwh

Systems

- Heat pump

- Wood boiler

- Heat pump

- No cooling system

- humidity sensitive Air Handling Unit (hygro A

- No renewable energy systems

Urban environment

- 1 097,00 m2

- 25,00 %

- 500,00

Product

PARNATUR HEMP COATING BODY

PAREXLANKO

CYRIL LEMOING cyril.lemoing[a]parex-group.com

https://www.parexlanko.com/frGros œuvre / Structure, maçonnerie, façade

With its simplified implementation using a coating spraying machine, this innovation provides additional thermal and acoustic insulation and can, if necessary, compensate for planimetric defects, thanks to a thickness of implementation. possible from 2 to 8 cm. A concrete and effective response for all construction professionals to the new challenges of energy transition, PARNATUR CORPS D'ENDUIT HANVRE is an innovative two-component solution, consisting of a lime-based binder and a bio-based aggregate, the hemp hemp. PARNATUR CORPS D’ENDUIT HANVRE can be applied both indoors and outdoors by mechanical spraying. It is compatible with a wide variety of old building supports (rammed earth, rubble stone, brick, mud, natural stone, hemp concrete, etc.) and can be combined with a wide choice of definitions from the PAREXLANKO HERITAGE range. PAREXLANKO HEMP COATING is the 1st projectable biobased solution on the market with excellent thermal (λ = 0.066 W / mK), hygrothermal (Moisture Balanced Value - MBV 2.9) and acoustic (transmission loss 53 dB for 5) performance. cm thick).

PARNATUR CORPS D'ENDUIT HEMP is appreciated by craftsmen already using hemp because this solution is much easier to apply, mechanical application, easier physically, with a high productivity 80 M2 / day against 30/40 M2 by manual and all without loss of product.

Construction and exploitation costs

- 230 000 €

Comfort

Life Cycle Analysis

Reasons for participating in the competition(s)

Performances to improve the daily well-being of the house throughout the year:

- Summer comfort ensured by the thermal inertia of the solution used to limit the entry of heat into the house

- Winter comfort thanks to the thermal insulation performance of the solution used while reducing the energy bill

- Comfort of life guarantees thanks to the product's permeability to water vapor, which limits condensation in the walls and the development of molds and microorganisms

- Finally, acoustic comfort is also optimized thanks to the solution which improves the acoustic insulation of the walls.

In addition, the lime and hemp-based biobased facade plaster shows that the client wanted to use bio-based materials, in particular making the quality of the indoor air healthier.