Palazzo Méridia office building in Nice (France)

Last modified by the author on 14/11/2022 - 14:23

New Construction

- Building Type : Office building < 28m

- Construction Year : 2018

- Delivery year : 2019

- Address 1 - street : Zone Méridia, avenue Simone Veil 06200 NICE, France

- Climate zone : [Csa] Interior Mediterranean - Mild with dry, hot summer.

- Net Floor Area : 8 622 m2

- Construction/refurbishment cost : 13 500 000 €

- Cost/m2 : 1565.76 €/m2

-

Primary energy need

32.9 kWhep/m2.an

(Calculation method : RT 2012 )

The Palazzo Méridia is an office building with a wood structure and positive energy , located at the corner of Avenue Simone Veil and Avenue Julien Lauprêtre in Nice. It was built on the Nice Méridia ZAC, a former agricultural wasteland on the Var plain as part of the Eco-Vallée National Interest Operation.

Following a consultation conducted by the EPA, the project by the Nexity Entreprises / Architecture Studio team was named the winner on June 13, 2016.

The building in R+9 has a solid wood structure which required some 900 tons of wood of French origin at 70% in particular with the CLT of the Alsatian site of Schilliger which was supplied on the Vosges massif. With its 35 meters high, this building is the tallest wooden office building in France upon delivery !

This project is also the subject of a 10-year multi-technical maintenance and charges guarantee contract for a joint-ownership building.

Architectural description

Raised 9 floors on a largely open ground floor, it has a metal exoskeleton supporting the vertical circulations rejected on the periphery of the volume, as well as continuous balconies running all along the facades. It rests on a concrete base insulated by the exterior in glass wool.

The roof terraces, built in CLT, are accessible and encourage future users of the building to meet in these open spaces. They include an edible garden . Finally, the lower floors are made of concrete slabs giving the building some of its thermal inertia.

The bracing of this building in an earthquake zone is provided by concrete cores, resting on a parking floor.

In addition to the tertiary surfaces on the floors, the Palazzo Méridia houses commercial premises on the ground floor as well as an underground car park.

A project labeled E3C2 for its energy efficiency

The E+C- label, issued by Certivéa, assesses the energy balance of the building's uses and its greenhouse gas emissions over its entire life cycle. The first tertiary building in France to obtain the E3C2 level , Palazzo Méridia, testifies to Nexity's commitment to pursuing an ambitious low-carbon policy.

The building has also obtained the following labels to date: BDM Silver level (for design and construction - the operation component has not yet been assessed), BBCA and BEPOS Effinergie 2017.

Concretely, the E3C2 level obtained by the Palazzo Nice Meridia corresponds to:

- “Energy 3”: sobriety and energy efficiency, 40% reduction in consumption and use of 40 kWh/m2.year of renewable energy.

- "Carbon 2": this level requires work to reduce the carbon footprint both on the energy consumption of the building and on the choice of construction materials and technical equipment, with an analysis of the entire life cycle materials.

These performances have been achieved thanks to effective insulation , in particular:

- Wall insulation with glass wool

- low floorconcrete

- High-performance double glazing mounted on aluminum frames with thermal bridge breakers

In terms of equipment, the building is connected to a heating and cooling network . At the same time, double-flow ventilation allows good indoor air quality to be maintained. Lighting power has been optimized and presence/absence detectors have been installed in all premises. The desks also have an automatic dimming system to ensure constant lighting. Finally, a photovoltaic installation makes it possible to cover more than half of the energy needs of the building .

Beyond the record height in wood and energy and carbon performance, this building is part of a global and innovative sustainable approach :

- 70% of the wood is of French origin (Vosges). Wood is also predominant in the interior fittings.

- Enhancement of natural spaces and shared edible vegetated space. The vegetation, witness to the agricultural past of the plain of the Var, is judiciously distributed around the perimeter of the building, extending the garden towards the canopy.

- Dry site limiting waste.

Key dates

- Submission of PC: November 29, 2016

- Delivery of the PC: June 13, 2017

- Start of work: April 2018

- Assembly of the tower crane: July 30 and 31, 2018

- Delivery: end of 2019

- E3C2 certification: September 2020

Photo credit

Antoine Duhamel

Contractor

Construction Manager

Stakeholders

Other consultancy agency

CBS-Lifteam

https://cbs-cbt.com/fr/realisations/Immeuble-de-bureaux,-Nice-(06)-6-0-101Calculation, construction

Construction company

Schilliger Bois SA

https://www.schilliger.ch/fr/referenz/palazzo-meridia-nice/French wood supply

Certification company

Certivéa

https://certivea.frThermal consultancy agency

BG Ingénieurs Conseil

marseille[a]bg-21.com - 04.91.25.53.53

https://bg-21.com/fr/Others

Tangram Architectes

Landscaper

Contracting method

Other methods

Energy consumption

- 32,90 kWhep/m2.an

- Heating: 11.5%

- DHW: 7.6%

- Lighting: 27%

- Breakdown: 27.5%

- Cooling: 26.3%

Real final energy consumption

32,90 kWhef/m2.an

Envelope performance

- 0,60

More information

- Primary energy consumption without solar production: 64.8 kWhep/m².year

- Solar production: 31.9 kWhep/m².year

Systems

- Urban network

- Individual electric boiler

- Urban network

- Double flow heat exchanger

- Solar photovoltaic

- 52,00 %

Product

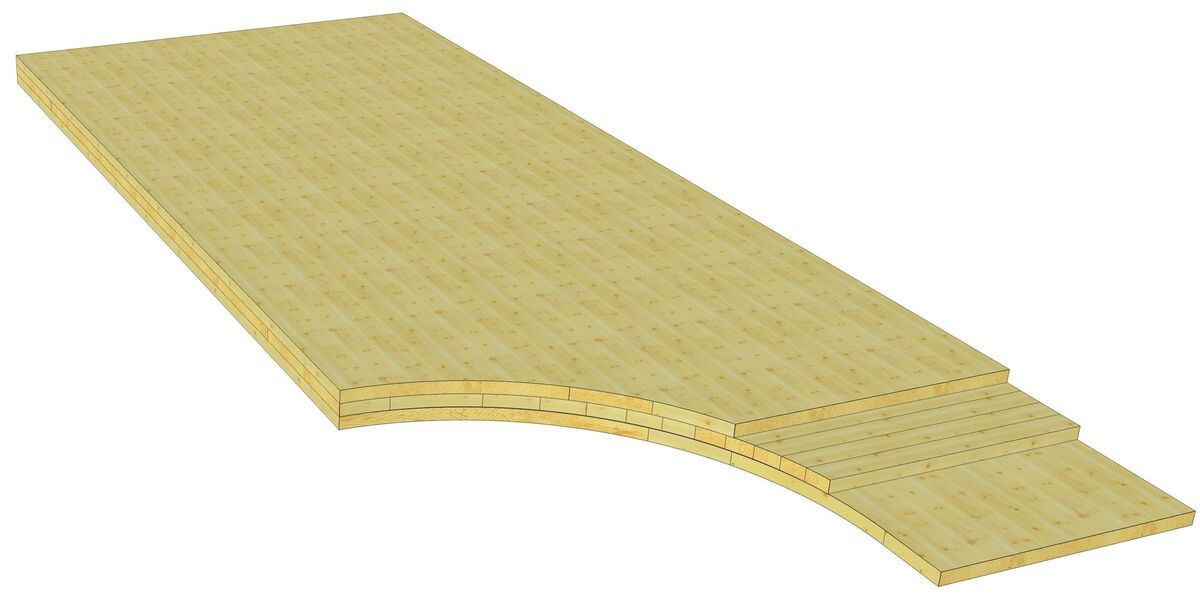

French wooden CLT

Schilliger

https://www.schilliger.fr/Cross Laminated Timber (CLT) was used for this project, making it possible to build wooden buildings taller and faster. The high degree of prefabrication of CLT panels allows the erection of a building in just a few days.

Beyond the advantageous properties (sustainable and renewable management, natural, zero carbon, waterproof insulation, hygrometry and quality of life, acoustics), their particularity is that they are made of French wood - only two manufacturers offer them in France!

The use of CLT is now well developed in France, but few are made from French wood. In addition, the philosophy of the CBS-Lifteam Group "More engineering, less material" has been applied because its ECOTIM factory has sourced just the necessary elements and which have been re-assembled on site without loss of material.

Construction and exploitation costs

- 13 500 000 €

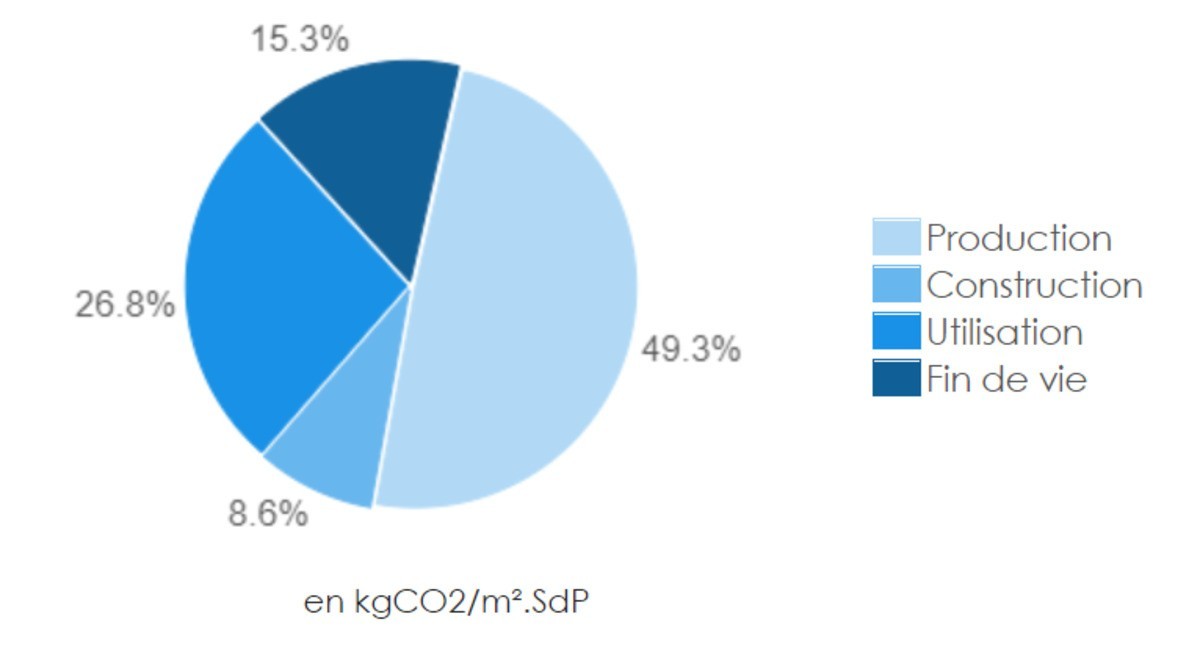

GHG emissions

- 5,00 KgCO2/m2/an

Life Cycle Analysis

- Output: 49.3%

- Building: 8.6%

- Usage: 26.8%

- End of life: 15.3%

Reasons for participating in the competition(s)

- First E3C2 certified office building in France.

- The tallest wooden office building in France upon delivery.

- A construction that gives pride of place to wood, 70% of which comes from the Vosges.

- Focus on energy efficiency and renewable energies.

- Obtaining numerous labels.

- A resilient construction in the face of seismic risks.

Building candidate in the category