Multipurpose room of Paillet

Last modified by the author on 23/03/2021 - 11:54

New Construction

- Building Type : Other building

- Construction Year : 2019

- Delivery year : 2019

- Address 1 - street : 27 avenue du chêne vert 33311 PAILLET , France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 500 m2

- Construction/refurbishment cost : 850 000 €

- Number of none : 1 none

- Cost/m2 : 1700 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : RT 2012 )

Construction of a multipurpose room for the town of Paillet.

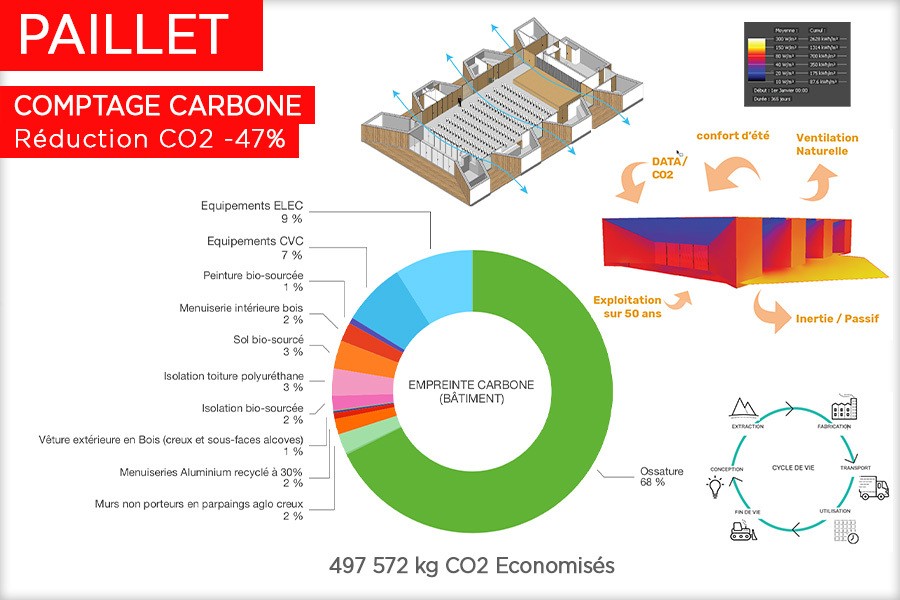

Carbon reduction approach: -47% of CO2 in Carbon Energy counting (Building + Operations) from the BIM digital model.

The environmental approach of the Paillet room was supported by the Nouvelle-Aquitaine Regional Council as part of the Bâtiment du Futur call for projects.

The strong carbon reduction is linked to the choice of products and equipment, but above all to the choice of the best energy (reduction in energy needs).

The solutions and improvements implemented on the project:

Building:

- Low carbon concrete (foundations and superstructure)

- Off-site concrete prefabrication of the framework

- Recycled materials (aluminum 30%)

- Bio-sourcing outer envelope (partial on shade alcoves)

- Second-work bio-sourcing (floors, walls, walls, interior coverings)

Bio-climatic:

- inertia of the shell (summer comfort)

- Solar control (before roofs)

- Thermal airlocks

- Natural ventilation (transverse sweeping focused on scorching winds)

Energetic:

- Heating Heat pump: Air-Water (power supply)

- Dual-flow CMV

- Passive cooling (without air conditioning)

>> Improved carbon reduction over 50 years:

- Building (in Kg saved and not emitted) = 124 911 Kg

- Energy (in Kg saved and not emitted) = 372 761 kg

>> Or -47% compared to the basic solution = a total of 497,672 Kg of CO2.

* It should be noted that the study of the restructuring of the multipurpose room of Paillet to give rise to the implementation of a decision support tool on the carbon impact of the future project.

- Evaluate the base solution

- Suggest and compare the difference in carbon reduction (eco-design)

- Calculate building CO2 and energy CO2 (over 50 years)

- Define a balance and a logic of choice (carbon results, financial impact in overall cost, comfort, label, etc.)

Sustainable development approach of the project owner

Paillet, a municipality labeled "bio-engaged territory", wished to take an exemplary approach to the challenges of sustainable development through this operation. This resulted in a Bio-climatic Design in Energy-Carbon Metering, centered on summer comfort, passive principles favoring natural energy and the use of bio-sourced materials. The project was thus the winner of the Batiments du Futur call for projects launched by the Nouvelle Aquitaine Region.

Thanks to the digital model (reliable quantitative data, thermal-dynamic simulations), the project was therefore carried out in carbon reduction, in particular by comparing the choices of eco-design in building physics and energy, with traditional responses. The use of thermal inertia of the building and natural ventilation, replacing air conditioning, combined with bio-sourced, geo-sourced and recycled materials have enabled a carbon reduction of 47% of CO2 over a life cycle of 50 years, i.e. around 500 tonnes of CO2 saved and a building that has half the impact (LCA construction and operation).

Architectural description

In order to reach sobriety and integration with the existing, the proposed volumetry is simple. Its rectangular base is also the result of a primarily functional and versatile room format for the various activities of the municipality.

In order to offer an opening towards the district and to have a controlled natural light, the openings were structured with an aim of partial transparency; combined with an eaves and blackout device allowing flexibility of use according to needs (open, closed + winter solar gain + summer solar control).

In this logic, thanks to large sliding glass frames, the room can really open up and be "through" which can temporarily become a hall open to the neighborhood. Moreover, this logic of hollows and permeability avoids the “box” effect of a building that is too closed in its context.

Noble and durable materials have been offered in relation to the surrounding environment. The exterior walls are in polished concrete in a light shade (durability + albedo). The hollows in the facade and under the eaves are made of slatted wood slats (local maritime pine, class 4 autoclave treated in brown color, to prevent any premature aging of these areas, however, being totally protected).

The approach proposed here is to assert the truly contemporary dimension of this new inter-municipal facility oriented towards the Future and Sustainability (bio-climatic architecture), while seeking a form of restraint and sobriety vis-à-vis the heritage context present.

See more details about this project

http://www.hobo.fr/projets/pailletPhoto credit

Hobo

Contractor

Construction Manager

Stakeholders

Designer

IG CONCEPT

Other consultancy agency

Lignes Environnement

Type of market

Global performance contract

Energy consumption

Envelope performance

More information

As part of the regulatory thermal study following the decree of October 26, 2010 relating to the thermal characteristics and energy performance requirements of new buildings, the multipurpose room building by its use is not subject to thermal regulations RT2012 in accordance with document seal from CSTB. However, in accordance with the requirements of the text, the challenges of reducing the energy consumption of the building have been taken into account at the project level with in particular a thermally efficient envelope, controlled lighting power, low-energy technical equipment and controlled management of the equipment. .

Systems

- Heat pump

- Water radiator

- Urban network

- No cooling system

- Natural ventilation

- Nocturnal ventilation

- Double flow heat exchanger

- Heat pump

Urban environment

Product

ECOCEM Concrete Framework - low carbon

ECOCEM

https://ecocem.fr/Gros œuvre / Structure, maçonnerie, façade

> Use of low carbon concrete. ECOCEM's raw material is a granulated slag, obtained from blast furnace slag suddenly cooled in a "granulator". It stems from the circular economy. The chemical composition of granulated slag is remarkably stable, it is checked by analysis every hour, as well as its mineralogical composition. The granulated slag is dried and then finely ground so that it can be used as a substitute for cement, in particular in concrete. The transformation operations are therefore carried out in a crusher. In France, at Fos-sur-Mer and Dunkirk, this is a latest generation vertical mill, consuming little energy, and powered by a hot natural gas generator which recovers unused energy.

This solution was easily adopted because of its lower carbon level than a standard CEM1 concrete, here we had a reduction of 26% compared to a standard concrete (67T of CO2).

Off-Site Prefabrication

Gros œuvre / Structure, maçonnerie, façade

The prefabrication allowed better management of structural work waste on the site and also contributed to the carbon reduction of the project with in addition a better finish because it comes directly from the manufacturing plant (improved finish).

30% recycled aluminum joinery

Second œuvre / Menuiseries extérieures

The use of recycled aluminum compared to standard aluminum allowed a carbon reduction of 1540Kg of CO2 on the project.

Maritime Pine Wood Exterior Cladding

Gros œuvre / Structure, maçonnerie, façade

The use of Maritime Pine wood unlike composite wood as provided for in the basic solution allowed a carbon reduction of 4.6T of CO2.

The more natural aspect of Maritime pine allows easy insertion into the environment and in line with current climatic issues.

Cooling / natural ventilation

Gros œuvre / Système passif

The non-use of air conditioning for the benefit of management and in-depth study of passive natural cooling allows the project to significantly reduce energy needs.

Wood wool insulation

Second œuvre / Cloisons, isolation

The use of wood wool unlike the rock wool initially planned allows a reduction of almost 5T of CO2.

Marmoleum Natural Flooring

FORBO

https://www.forbo.com/Second œuvre / Revêtements de sol

>> The installation of a natural 'Marmoleum' floor covering, unlike a PVC floor initially planned, allowed a carbon reduction of 1.9T of CO2. This natural soil based on linseed oil as a raw material is obtained by crushing flax seeds. The use of wood flour fixes the pigments and guarantees the fastness of the colors throughout the life of the product. The wood flour used here comes from sustainably managed forests and not from tropical wood flour. All the colors of the coating are obtained from pigments devoid of heavy materials such as lead and cadmium and therefore do not harm the environment. The resin which is extracted from the pine without affecting its growth, serves as a binder for the linoleum. Mixed with linseed oil, this gives it strength and flexibility.

Peinture unikalo

UNIKALO

https://unikalo.com/Second œuvre / Peinture, revêtements muraux

The use of Unikalo paint allowed a reduction of 2.5T of CO2 compared to a standard paint. > The paint used is based on natural, bio-based and renewable components. * Without substances dangerous for the ozone layer - Without pesticides - Without phthalates - Without heavy metals - VOC <1g / L - Without solvents - Without mutagenic carcinogenic agent and Reprotoxic - No formaldehyde - No nanomaterials

Construction and exploitation costs

- 1 000 000 €