Extension of L'Oréal factory

Last modified by the author on 24/03/2021 - 15:50

Extension

- Building Type : Factories

- Construction Year : 2019

- Delivery year : 2021

- Address 1 - street : Avenue Henri Lefebvre 59540 CAUDRY, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 3 393 m2

- Construction/refurbishment cost : 7 700 000 €

- Number of Installed Kw : 119 Installed Kw

- Cost/m2 : 2269.38 €/m2

Certifications :

-

Primary energy need

-79.2 kWhep/m2.an

(Calculation method : RT 2012 )

The program for the extension of the L'Oréal SICOS plant in Caudry aimed to integrate the possibilities of valuing renewable energies for the benefit, first of the extension, then of the plant.

First of all, a reduction in needs through an architectural envelope made from high-performance local biosourced materials, displaying the new generation of industrial buildings with ambition level RE 2050. Elevations in wood-straw boxes covered with saturated wood cladding.

Then, the project presents several technologies of natural low temperature energy transfers:

- aerovoltaics for the production of electricity and daytime hot air or fresh night air (324 m²).

- 36 geothermal probes at a depth of 190 m, ie 6,840 ml of transfer of calories and frigories in inter-seasonal storage under the building to optimize the footprint on the ground.

- Reconstitution of the water table by infiltration retention of rainwater and geothermal recharge of probes.

Sustainable development approach of the project owner

"We want to be an exemplary company in terms of sustainable development and in particular in terms of the environment" Jean Paul Agon, June 2012, CEO L'Oréal group.

Goal.

Consider the 3,500 m² extension of the existing 50,000 m² plant, an exemplary break with traditional design approaches, in order to bring out environmental possibilities, particularly renewable energy.

Original ambition.

Consider remedies:

o Biosourced materials from the architectural envelope to reduce thermal needs.

o The natural energies of the site and their use in the service of the extension project, but also for the benefit of the existing plant, if possible.

First green building.

It is the programmatic importance of the plant extension operation that made it possible to initiate an exemplary project approach with a spirit of openness to virtuous environmental innovation.

From the program provided, it was the subject of holistic re-questioning which continued as a dynamic driver during the phases of design, consultation of companies, development of PEOs, execution performance, refinement and perseverance of finalization. new emerging technologies.

Architectural description

The Sicos (Caudry) site of the L'Oréal group specializes in cosmetic emulsion products. The objective of the project was to bring together the stocks of alcohol in a dedicated place, contiguous and isolated from the factory.

The extension of approximately 3,400 m² on the ground, 10 meters under the ceiling, adjoining the plant, was built in a reinforced concrete structure with a large range anti seismic level 3, associated with an insulating jacket in wooden boxes filled with bundles of straw, fireproof 2h.

The infrastructure piles (20 m), coexist with the 36 vertical geothermal probes 190 m deep.

The superstructure in reinforced concrete beams, long span, supporting pre-stressed alveolar slabs receives on the exterior vertical walls, the wooden boxes with filling in bundles of compressed straw, modulated on the constructive grid.

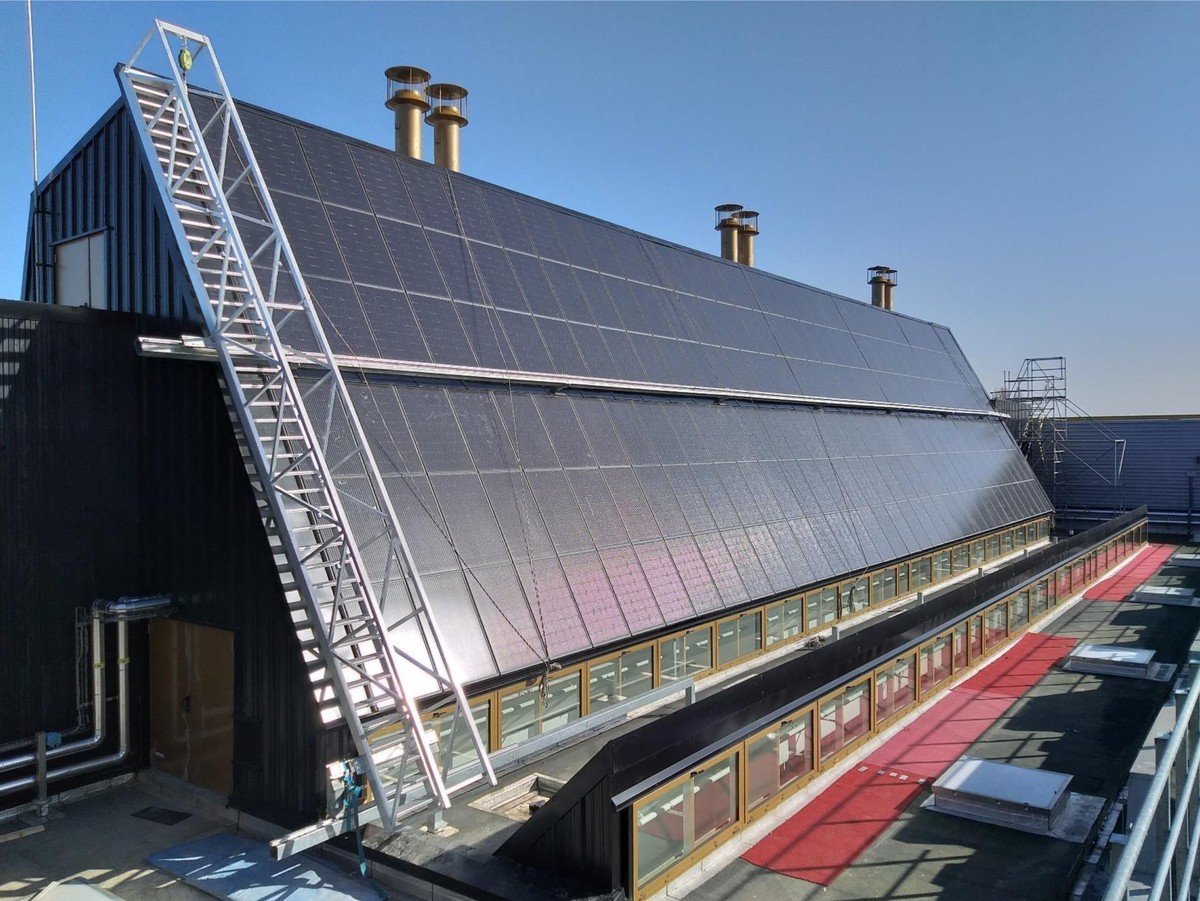

A wooden frame, placed on the roof terrace, houses all the technical equipment such as exchangers, heat pumps, buffer tanks, etc. and receives the 216 aerovolatical sensors on its southern slope.

See more details about this project

Photo credit

Jean-Luc Collet

Contractor

Construction Manager

Contracting method

Other methods

Energy consumption

- -79,20 kWhep/m2.an

- 114,10 kWhep/m2.an

Real final energy consumption

14,50 kWhef/m2.an

Systems

- Heat pump

- Geothermal heat pump

- Tape

- Aerotherm Heater

- Solar thermal

- Heat pump

- Solar Thermal

- Reversible heat pump

- Geothermal heat pump

- Tape

- Double flow heat exchanger

- Solar photovoltaic

- Solar Thermal

- Heat Pump on geothermal probes

- Heat pump

Urban environment

Product

Prefabricated wooden frame boxes with straw infill

ACTIV'HOME

Gros œuvre / Structure, maçonnerie, façade

190 m deep vertical geothermal probes

GEOFORAGE

Water-to-water heat pumps

TRANE

Aerovoltaic solar collectors

SYSTOVI

Second œuvre / Equipements électriques (courants forts/faibles)

Construction and exploitation costs

- 740 000 €

- 8 440 000 €

- 880 000 €

Reasons for participating in the competition(s)

The objective of the project was to bring together the stock of alcohol in a dedicated place, isolated from the factory. The extension of approximately 3,400 m² on the ground, 10 meters under the ceiling, adjoining the plant, was built in a level 3 earthquake-resistant structure, associated with an insulating jacket made of wooden boxes filled with bales of local straw.

The self-supporting and prefabricated modular wood / straw boxes made it possible to quickly remove air and water from the vertical walls. They are dressed with an exterior cladding, in Douglas-fir from Haute Savoie, saturated. The wooden structure sheds bring natural light into the labs. 36 vertical geothermal probes make it possible to exploit the natural resources of the subsoil, 324 m² of aerovoltaic solar collectors, placed on a wooden frame, produce electricity, hot air during the day and cool at night, recovered by exchangers and reinjected into the hydraulic factory networks.

The infrastructure piles coexist with 36 vertical geothermal probes 190 m deep. The superstructure made of reinforced concrete beams, long span, supporting pre-stressed honeycomb slabs receives on the exterior vertical walls, the wooden boxes with filling in bundles of compressed local straw, modulated on the construction grid. A wooden frame, placed on the roof terrace, houses all the technical equipment such as heat exchangers, heat pumps, storage tanks, etc. and receives the 216 aerovolatical sensors on its southern slope.

Building candidate in the category