ECOCAMPUS Provence : New and Renewable Energies Training and Learning Center

Last modified by the author on 30/10/2020 - 15:10

New Construction

- Building Type : School, college, university

- Construction Year : 2016

- Delivery year : 2018

- Address 1 - street : 445, rue Gabriel Besson 04 SAINTE TULLE - MANOSQUE, France

- Climate zone : [Csa] Interior Mediterranean - Mild with dry, hot summer.

- Net Floor Area : 4 099 m2

- Construction/refurbishment cost : 7 460 000 €

- Number of Pupil : 400 Pupil

- Cost/m2 : 1819.96 €/m2

Certifications :

-

Primary energy need

38 kWhep/m2.an

(Calculation method : RT 2012 )

This building was awarded the Sustainable Construction Grand Prize of the Green Solutions Awards 2020-21 at the national level; and a mention for the same category at the international level.

The Ecocampus Provence, New and Renewable Energies Training and Learning Center, is part of a global urban development operation in the town of Sainte Tulle (04) including the establishment of economic activities, the construction of housing and the development on the site of the former "Ecole des Métiers" of EDF of tertiary activities and training dedicated to new and renewable energy professions. The establishment will accommodate 350 to 400 learners. The level V to VII training offer is supported by CCIT 04 and will subsequently be extended by level V to I training courses offered by other partners.

The Ecocampus Provence is designed as an emblematic building , a driving force that will bring a new dynamic to the campus site and more generally contribute to the development of the "Vallée des Energies Nouvelles": Manosque / La Durance / Cadarache.

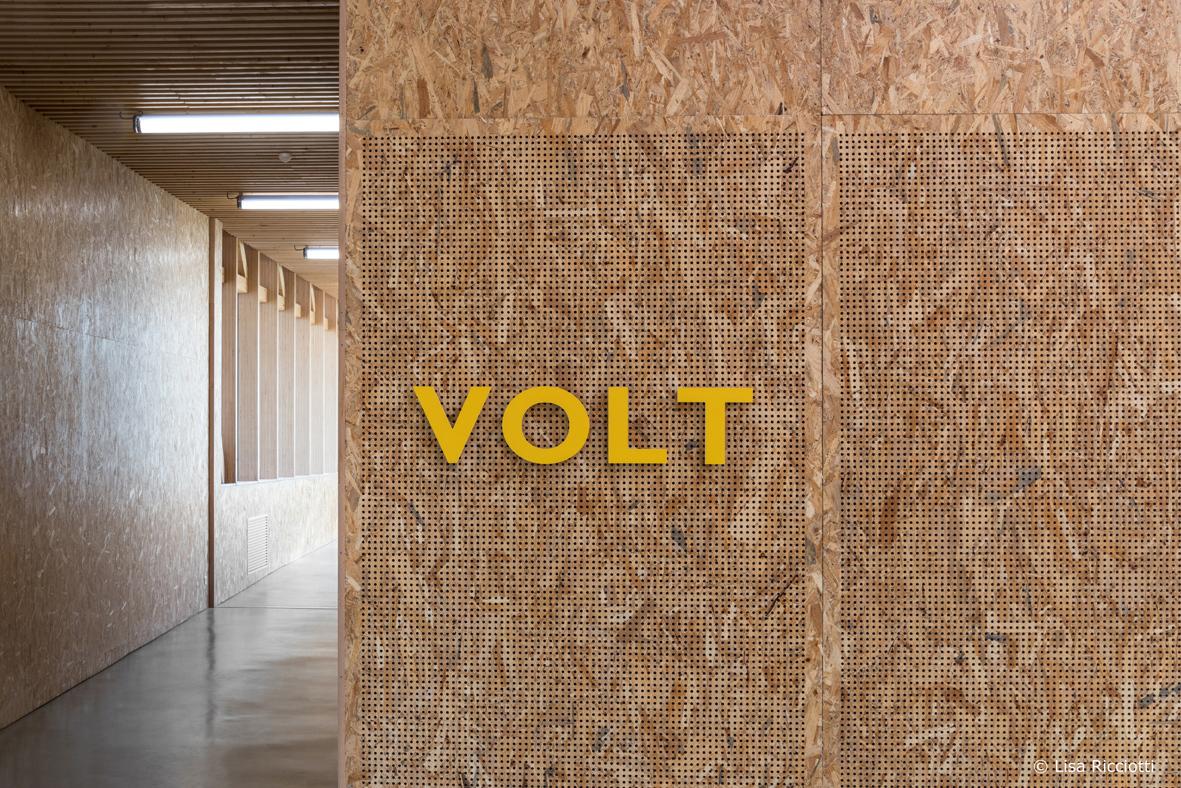

Exemplary in terms of sustainable construction, the CFA Energies Nouvelles et Renouvelables is the architectural expression of scientific research carried out in the environmental field and promising for the future. The building is structured around an interior street and two covered patios, buffer spaces, giving access to the different entities, designed as places of relaxation, exchanges (forum of trades, exhibitions, meetings of partners) and experiments. for learners. These inter-climatic distribution spaces are the establishment's reference points, user-friendly, educational, representative of the project's inclusion in a sustainable concern.

Our desire for the building to participate in the pedagogy provided by the CFA guided the design choices allowing learners to test full-scale devices relating to new energies and taking into account the comfort induced for all:

- Strong bioclimatic design of the interior street and patios.

- Focus on solar energy (solar heated floors) and photovoltaic production in the glass roof.

- Use of natural ventilation (Provencal well), vegetation on the roofs and in the patios under photovoltaic glass roofs, possible misting of the patios for summer thermal comfort.

- Connection to raw water for watering green spaces and green roofs .

- Installation of the wood- fired boiler on the technical teaching platform.

- Location and accessibility for all of the technical and green terraces .

Building users opinion

Overall through the BDM OR monitoring over 3 years (still in progress) of this project, user feedback is rather favorable except for the level of administration at R + 1 or during the heatwave period of the last summer (2019), the occupants complained about the constant high temperature: it was proposed the installation of air fans and night ventilation (which had not been put in place due to intrusion of insects and other animals that set off the alarms). In progress.

It should be noted that the innovative project approach initiated by the Client (DLVA) was ambitious. However, this type of construction requires the implementation of rigorous management with monitoring (partly provided by the BDM mission) and the setting up of maintenance companies throughout the process. Building maintenance and upgrading interventions have been recommended but have not always been implemented.

If you had to do it again?

The structural problem of timber construction in a very strong seismic zone (localization on the fault) requires special attention from all the actors throughout the operation, forcing them even more than usual to work in consultation: architects, design offices and companies in the design phase as well as during the execution. Incorporating the earthquake-resistant provisions has repercussions on many structural works but also on the envelope and therefore concerns many building trades. Everyone's attention and collaboration is therefore essential to enable the construction of a building that guarantees the safety of its occupants during a major seismic event. We are satisfied with the result and the synergy of all the teams, but the operation required a significant investment from all stakeholders in order to achieve this achievement under the best conditions, taking into account the ambitious environmental objectives that had been set. posed from the outset and which constituted an additional constraint. In addition, concerning the finishing of the building envelope, the Project Owner (DLVA) absolutely did not want exterior wood cladding (neither pre-gray wood or autoclaved): we therefore opted for opal polycarbonate which gives the interior wood structure a transparent view. But the installation of such a material remains very demanding and delicate.

See more details about this project

https://www.leteissier-corriol.fr/projet/cfa-energies-nouvelles-pour-lecocampus-de-sainte-tulle-04/http://www.leteissier-corriol.fr/wp-content/uploads/2015/01/architecte-marseille_leteissier-corriol_version-definitive_forum-bois-nancy_cfa-sainte-tulle_leteissiercorriol.pdf

https://www.leteissier-corriol.fr/ecocampus-prix-de-la-construction-bois-2020/

https://www.leteissier-corriol.fr/ecocampus-provence-sainte-tulle-amc/

https://www.leteissier-corriol.fr/avancement-chantier-de-lecocampus-de-sainte-tulle/

Photo credit

Lisa RICCIOTTI and Florent JOLIOT

Contractor

Construction Manager

Stakeholders

Construction Manager

LETEISSIER CORRIOL Architecture & Urbanisme associé Marseille (13)

Elisabeth LETEISSIER (04 91 48 04 00)

https://www.leteissier-corriol.fr/Thermal consultancy agency

ADRET Embrun (05)

Chantal LAROUTURRE (06 78 12 27 74)

http://www.adret.net/Fluids / SSI / Environmental Quality / BDM process monitoring

Structures calculist

GAUJARDTECHNOLOGIE SCOP Avignon (84)

Mariette GOUGER (04 90 86 16 96)

http://bet-gaujard.com/wp/Timber structure in strong seismic zone (fault)

Company

ARBONIS Verosvres (71)

Christophe EGLIN (06 71 27 69 17)

http://www.arbonis.com/Wooden structure and exterior polycarbonate cladding

Certification company

Bâtiments Durables Méditerranéens (BDM) Marseille (13)

Frédéric CORSET (04 95 04 30 44)

https://www.envirobatbdm.eu/index.php/jevalue-mon-projetBDM GOLD level approach

Site manager

ECOCAMPUS PROVENCE - 445, rue Gabriel Besson Sainte Tulle (04)

Thierry BENVENUTI - Responsable du pôle formation - CCIT Alpes de Haute Provence - (04 92 70 75 23)

https://www.ecocampusprovenceformation.fr/Person who was responsible for monitoring and setting up maintenance - User contact within the framework of BDM monitoring.

Type of market

Global performance contract

Energy consumption

- 38,00 kWhep/m2.an

- 52,00 kWhep/m2.an

Real final energy consumption

40,00 kWhef/m2.an

Envelope performance

- 0,36 W.m-2.K-1

- 0,33

- 1,00

More information

The Ecocampus building is still undergoing a BDM operational phase evaluation (duration over 3 years). In fact, there are 3 phases in the BDM process: the project has been assessed BDM OR in the design and construction phases. We have been evaluating all consumption for almost 3 years to draw the balance sheets by the end of 2020.

Systems

- Water radiator

- Low temperature floor heating

- Radiant ceiling

- Wood boiler

- Solar thermal

- Individual electric boiler

- No cooling system

- Nocturnal Over ventilation

- Free-cooling

- compensated Air Handling Unit

- Double flow heat exchanger

- Solar photovoltaic

- Solar Thermal

- Biomass boiler

- 100,00 %

Smart Building

Urban environment

- 13 797,00 m2

- 27,00 %

- 3 707,00

Product

LVL (lamibois) of beech (interior street poles).

BAUMUCHE de POLLMEIR

Nous sommes allés visiter l'usine en Allemagne et réceptionner in situ les poteaux pour en garantir la finition.

https://www.pollmeier.com/fr/Produits/a-propos-du-BauBuche

Beech (lamibois) LVL is a glued laminate, that is to say it is very dense, offers great resistance in an interesting visual finesse. Another advantage, and not the least: there is no loss of wood in this process.

The use of beech LVL made it possible to resolve structural problems inherent to the site while retaining a certain finesse for these supporting posts of the interior street.

BIOFIB'TRIO ISOLATION

Biofib’trio, isolant bio-sourcé à base de chanvre de la marque Biofib’isolation

https://www.biofib.com/biofib-trio/Second œuvre / Cloisons, isolation

Biofib’Isolation is a leading brand in the bio-sourced hemp-based insulation market. Its products are made from renewable plant fibers which are increasingly appealing to artisans and consumers. The range, which consists of bulk, rigid or semi-rigid products, is capable of responding to all construction applications. Biofib’Isolation insulation is made from renewable plant fibers from local agriculture. All the products in the range provide undisputed thermal performance, which naturally leads to energy savings.

In addition to their recognized and certified performance (ACERMI), the insulators guarantee genuine installation comfort for all building professionals.

Their 100% natural fibers are recyclable, perfectly healthy and non-irritating.

The absence of dust at the installation level facilitates installation and does not require any special precautions.

Today this insulating product is available in all stores in France.

This thermo-acoustic insulation is made of hemp, linen and cotton. ACERMI certified and under technical advice, it is highly appreciated for its breathing and regulating powers, which provide the home with a healthy, stable and comfortable atmosphere

The CFA Energies Nouvelles was designed as an emblem in which the materials selected express a strong relationship with nature. All of the products used were installed with a concern for the durability, longevity and scalability of the building.

On the insulation side, the use of hemp was prescribed by the architects and the owner to be the basis of the insulation. Hemp is a plant resulting from a sustainable and annually renewable culture, which offers technical and structural advantages that are increasingly appreciated: good regulation of hygrometry, phase shift and optimum thermal resistance. To date, Biofib’s insulation is the only brand to offer insulating products made from hemp, ACERMI certified and under technical advice. A guarantee of quality and performance which made the difference on this project.

Autonomous solar street lights from LUMIN'IN

LUMIN'IN FRANCE

http://www.lumi-in.fr/Aménagement extérieurs / VRD, assainissement

It is rare in the context of the construction of public equipment to be able to install autonomous solar lights in full outdoor lighting, notably reducing energy consumption for users.

As already integrated ("Energy" tab), the DIALUX study made it possible to convince users and the Client of the validity of this proposal for autonomous exterior night lighting.

Construction and exploitation costs

- 13 000 000,00 €

- 14 000 000,00 €

- 562 500,00 €

- 952 760 €

- 9 968 000 €

- 5 295 000 €

Energy bill

- 17 000,00 €

Water management

- 863,00 m3

Indoor Air quality

Comfort

- Efficient sun protection for each orientation (see plan P41 of the environmental guide)

- An average inertia provided by the slab.

- Natural or mechanical night ventilation depending on weather conditions

- Strong greening of the surroundings

- A green and ventilated roof

- Crossing classrooms and practical work

- A covered patio promoting natural ventilation in the classrooms by creating a fireplace effect

- Vegetation and fresh air supply from the VS with outdoor air intake in shaded area for the patios.

- Floor: concrete or linoleum

- Walls: A + paints and VOC <1g / l or chipboard classified E1.

- Ceilings: chipboard E1, or wood + mineral wool A + EUCEB.