Condominium Le Bois du Coudray

Last modified by the author on 22/02/2019 - 14:29

Renovation

- Building Type : Collective housing > 50m

- Construction Year : 1980

- Delivery year : 1981

- Address 1 - street : 91830 LE COUDRAY MONTCEAUX, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 6 224 m2

- Construction/refurbishment cost : 1 426 000 €

- Number of Dwelling : 67 Dwelling

- Cost/m2 : 229.11 €/m2

-

Primary energy need

121 kWhep/m2.an

(Calculation method : RT existant )

In 2012, the condominium company embarked on a renovation process through an energy audit conducted by ASCAUDIT Energie.

Thanks to the union council which was the driving force at the kick-off meeting, the co-owners found an interest in this audit (first step towards energy renovation) by responding massively to the usual survey: 60% of return.

Throughout the energy audit service, ASCAUDIT Energy has clearly identified the expectations of the co-owners:

Improve thermal performance of the building

Renovate the building for heritage enhancement

Lower the charges

Make the residence visually more attractive

Following the impetus of the syndic FONCIA LEMONNIER and the union council, these works were put in perspective with the state of obsolescence of the building which had not benefited from recent renovation. The resale of the apartments had become difficult. The initial budget of less than € 1 million for energy renovation was thus included in a global modernization project at € 1.4 million, taking into account the building's upgrading efforts.

At the end of 2016, ASCAUDIT Energie in quality of thermal BET and Pierre MULAS (Architect Mandatory) were retained in General Assembly for the project management of the joint ownership on the following batches:

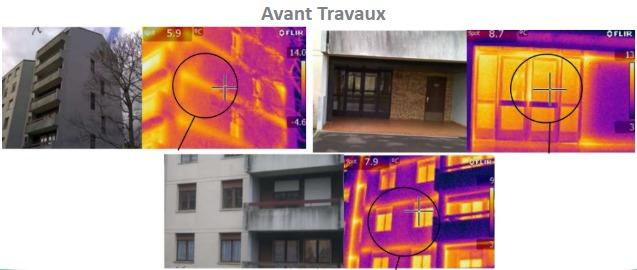

Exterior insulation of all exterior walls from the ground floor to the last level with 12 cm panels of expanded polystyrene (R> 3.7 m²K / W);

The insulation on the underside of the low floor with 12 cm of mineral wool sprayed (R> 3.0m²K / W);

The replacement of the openings by insulating glass panes with low emissivity, consisting of two 4mm glass windows by closing an argon plate with a minimum thickness of 16 mm, of the type with reinforced insulation (VIR) 4/16/4, equipped shutters or blinds (U <1.8 W / m².K);

Various modernization works

The energy savings (33%) generated by such works have allowed the condominium to move from energy class D (198) to C (121).

The work took place over a period of 12 months, and ended in late 2018

Sustainable development approach of the project owner

The co-owners, accompanied since the energy audit, were aware of the poor thermal performance of the residence, were willing to renovate the building envelope in order to save energy and preserve the heritage value of the whole.

Following a survey of the co-owners, Ascaudit was able to perceive the strong and weak points of the building seen by its occupants:

- comfort problems related to heating

- summer comfort problem

- acoustic comfort problem

- problem of tightness of the windows

- discomfort related to the phenomenon of cold paroies

The positive factors that have been put forward for this renovation are:

- lower energy costs

- improved winter and summer thermal comfort

- removal of thermal bridges

- no reduction in living space

- valuation of wealth over the long term

- improvement of the living environment

Waste management was an element to which the co-owners wanted the construction manager to pay close attention.

For this, what has been written about cleaning during construction:

The contractor responsible for the construction site must:

- carry out these cleanings as and when the progress of its work, the daily evacuation of its rubble and waste, in the buckets made available by the person in charge of the market

- after reception, ensure the fine cleaning in the premises where he will intervene to lift the reserves.

- be in charge of storage tanks for rubble and waste (selective sorting)

The cleanliness of the site must be maintained steadily. The supervisor reserves the right, in the event of failure to comply with this requirement, to have the corresponding cleaning carried out as many times as is necessary by a company of his choice and at the expense of all the companies pro rata of their market.

The daily cleaning of the cantonments and offices was carried out by the general contractor missioned until reception.

In particular, the company was responsible for installing and folding as many times as necessary a gravel dump truck during the entire construction period.

Architectural description

The LE BOIS DU COUDRAY condominium located at 23/25/27 rue Gabrielles d'Estrées at Coudray Monceaux is made up of 3 semi-detached buildings (R + 6) and (R + 7) with a similar design under the eaves. built in 1980. The façades had a simple concrete balcony with limited insulation (RT 74). The roofs are equipped with crawling outfits. The set is completed by 2 blind gables.

Building users opinion

"The condominium was a real Gruyère, we were very cold during the inter-seasons ..." [...], "it was a real hell"

"we wanted to do something to improve the quality of the condominium"

"We wanted to prevent the building from being devalued"

"we are very satisfied with the construction, the deadlines and the support"

"satisfaction of all the co-owners"

If you had to do it again?

Tripartite satisfaction:

- the developer: Foncia

- the co-owners

- The arch and BET Thermal

See more details about this project

Contractor

Construction Manager

Stakeholders

Thermal consultancy agency

ASCAUDIT ENERGIE

HERVE LASSEIGNE

https://www.ascaudit.comCompany

COULON

contact (a) coulon-sa.fr

http://www.coulon-sa.com/Company

LORENOVE

https://www.fenetres-lorenove.fr/Type of market

Global performance contract

Energy consumption

- 121,00 kWhep/m2.an

- 180,00 kWhep/m2.an

- 177,00 kWhep/m2.an

Real final energy consumption

112,00 kWhef/m2.an

2 018

Envelope performance

- 0,64 W.m-2.K-1

More information

Heating: 45% saving (120-> 66)

Improved thermal comfort in dwellings

Systems

- Low temperature gas boiler

- Low temperature gas boiler

- No cooling system

- compensated Air Handling Unit

- No renewable energy systems

Urban environment

Product

STO THERM CLASSIC TOP 31

STO

http://www.stothermclassic.fr/Second œuvre / Cloisons, isolation

ITE (External Thermal Insulation) Studded system, finish

by coating

• Sto Therm Classic System with StoArmat Classic wedged-pegged

• PS 12 / SE stopoly RT + insulation (λ = 0.032) with graphite particles

(Insulation 12cm)

• CE marking, ACERMI certified

• Finish: Coated

Location: Facades and gables from R + 1

ITE Anchored wedge system, reinforced plaster finish

• Sto Therm Classic System with StoArmat Classic wedged-pegged

• PS 12 / SE stopoly RT + insulation (λ = 0.032) with graphite particles

(Insulation 12cm)

• CE marking, ACERMI certified

• Sto-Fiber shielding

• Finish: Coated

Location: Set of foundations

StoTherm Classic insulation solutions fit perfectly whatever the purpose of the structure.

StoTherm Classic allows you to:

- give a personalized architectural identity

- make an aesthetic, economic and sustainable investment

- optimize job sites thanks to ready-to-use

Density adapted for

- More summer comfort;

- More acoustic comfort;

- Excellent wind stability.

- Negligible settlement.

- Thermal performance.

- Stable in time.

Rockwool - rockwool rockair

Rockwool

https://www.rockwool.fr/contact/contact-service-commercial/

https://www.rockwool.frSecond œuvre / Cloisons, isolation

ROCKAIR is used for the insulation of attics lost by mechanized blowing.

ROCKAIR is used for the insulation of attics lost by mechanized blowing.

Cladding - TRESPA

• Cladding - TRESPA or similar on wooden frame

• Ventilated attached cladding panel consisting of flat panels with

base of thermosetting resins reinforced so

homogeneous by wood or cellulosic fibers and manufactured under

high pressure and high temperature.

• Sto rock wool panel with non-woven (lambda:

0.035 W / (m.K), 130 mm minimum thickness (13cm insulation)

• Dark brown TRESPA finishes

Joinery AGS 6060

AGS

http://www.fbcg.fr/aluminium-ags-6060-c6x23633339Second œuvre / Menuiseries extérieures

Exterior wood furnishings

· Aluminum type, the profiles will be spun in an AGS reference alloy

6060. They will be lacquered, benefiting from the label qualicoat and a treatment

marine range guaranteed 10 years.

· Dark brown color (same as existing)

· The joinery will have fine profiles and technology opening hidden

· Insulating glass with low emissivity layer

· Blade: 16 mm Argon 85%

· Thermal coefficient of glass Ug = 1.1,

· Thermal coefficient of the window (door window) Uw = 1.3 W / m².K

· TL Light Transmission: 60%

· Solar factor SW = 0.33

· Acoustic level dB (a): 30

· Mechanical Performance (Air / Water / Wind): A * 4 E * 7B V * 2

Construction and exploitation costs

- 1 426 000 €

Comfort

GHG emissions

- 23,00 KgCO2/m2/an

Reasons for participating in the competition(s)

In 2012, the condominium company embarked on a renovation process through an energy audit conducted by ASCAUDIT Energie.

Thanks to the union council which was the driving force at the kick-off meeting, the co-owners found an interest in this audit (first step towards energy renovation) by responding massively to the usual survey: 60% of return.

Throughout the energy audit service, ASCAUDIT Energy has clearly identified the expectations of the co-owners:

Improve thermal performance of the building

Renovate the building for heritage enhancement

Lower the charges

Make the residence visually more attractive

Building candidate in the category

Energie & Climats Tempérés

Prix du public