Capoeira

Last modified by the author on 08/06/2021 - 17:54

Renovation

- Building Type : Isolated or semi-detached house

- Construction Year : 1900

- Delivery year : 2017

- Address 1 - street : 66 rue d'Etigny 64000 PAU, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 174 m2

- Construction/refurbishment cost : 113 446 €

- Number of Dwelling : 1 Dwelling

- Cost/m2 : 651.99 €/m2

-

Primary energy need

134 kWhep/m2.an

(Calculation method : RT 2012 )

The project consists of the transformation of an old restaurant of the churrascaria type, named “La Capoeira” and located in Pau, into a main residence on the basis of bioclimatic principles and of deconstruction and reuse of in-situ materials. This restaurant was transformed into a townhouse by removing part of the roof of the dining room which became a courtyard and by creating a south-facing greenhouse facade at the level of the kitchens and offices, thus delimiting the accommodation.

The house, located in the north at the end of the plot, is organized on two levels. On the ground floor, a large living room wraps around the greenhouse to compensate for the lack of opening in other directions.

The courtyard created in the center of the plot is put back into a natural state by the removal of the original concrete slab, and a revitalization of the soil with phyto-remediation is put in place to treat the oil pollution due to the space being a garage beforehand.

This yard comprises a rainwater collection tank and water-saving devices, including toilets with bio-controlled litter, which complete the management of water resources.

The project is based on maximizing the value of what already exists, both in terms of the organization of spaces and construction technique.

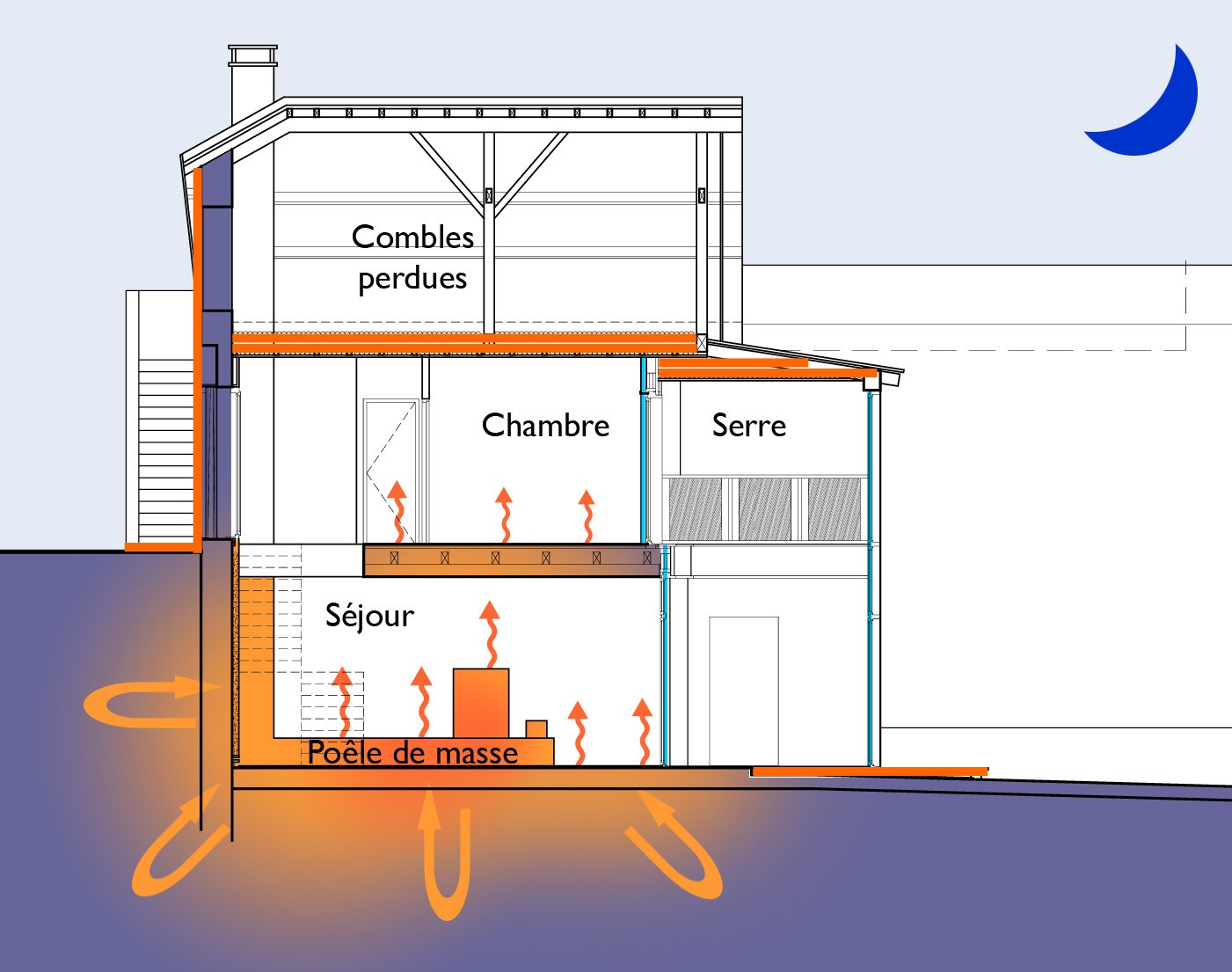

Thus, the house retains the original floors, framework and roofing, and develops in such a way as to maximize passive solar gains. These contributions are supplemented in the cold season by a rocket type mass stove, while the thermal mass of the building will ensure good conditions in the hot season.

Likewise, this approach leads to managing the site in such a way as to enhance the value of the materials resulting from the deconstruction by integrating them into the renovation. The facade created is in wood frame, part of which comes from the existing frame; the wooden frame and the mechanical tile roofing have been completely revised with the framework and the tiles removed from the dining room roof; all finishing materials as well as equipment are deposited and reused in the house; materials deposited that cannot be reused identically are diverted to other functions.

Ultimately, the project provides for the integration of photovoltaic solar panels and DHW, resulting from the deconstruction, to complete the energy production systems.

Sustainable development approach of the project owner

My various professional experiences in an architectural agency in parallel with my studies in Paris made me aware of the phenomenal quantity of materials ending up in waste centers during projects. Coming from a modest family in the countryside where you keep everything because "you never know, it can always be useful", it was a real culture shock. At the same time, my student squat experiences ended up showing me the inanity of the productive system in which we live, and particularly with regard to construction. Leaving 5 million m2 of office space vacant in the Paris region, while demolishing enough to build thousands more, when the Abbé Pierre Foundation alerts us every year about the housing conditions of millions of people is quite simply ubiquitous.

... And again, that's not to mention the environmental cost.

It was therefore natural that, when my partner and I sought to settle in, we left with the following principles for our accommodation: a bioclimatic renovation in an urban environment, in deconstruction and reuse, with maximum experimentation and dissemination of the results.

In addition to the desire to reduce our carbon impact as much as possible, I wanted to train myself in re-employment in order to include it in my professional practice. This objective subsequently evolved through meetings to lead to the creation of the association IDRE-Interprofessionnelle de la Déconstruction et du Réemploi.

This is my first truly environmental building.

Unlike other projects, the design phase was much longer, in particular due to the constraints in terms of the availability of materials. Constant round trips between the listing and the project to check the quantities were necessary. On the other hand, a "flexible" design had to be fostered in order to be able to adapt to the future results of the deconstruction. This greatly facilitated the modifications on site, more numerous than usual to adapt to the materials. Finally, the organization required precise phasing and responsiveness to take advantage of opportunities.

In short, in the case of reuse, it is up to the architect (and the client!) to adapt to the materials and not the other way around.

The end result is a new construction in terms of quality and finish, sometimes even superior (isoplane fire doors in the bedrooms, professional equipment ...). But it is above all on the conservation of the building's memory within the site that the project stands out the most from the norm.

Architectural description

The two structuring elements for the whole project are the bioclimatic design and the heating system.

The building's urban location was the major constraint, with solar masks and large dividers but oriented to solar noon. This led to the design of a southern double-skin facade, designed with the thermal consultancy office to maximize solar gain. The interior organization of the spaces is driven by this facade.

Likewise, the choice of the mass stove was imposed in order to make the most of the thermal hyperinertia of the semi-underground building. In fact, this results in a central stove in the house, and not isolated from the ground in order to gradually raise the natural average temperature of the building. In order to further enhance its effect, the thermal battery has been positioned so as to also benefit from maximum solar radiation in winter.

The materials available on site also led to a specific architectural writing, and guided the choices for the purchase of materials (new or re-used).

Building users opinion

Overall good, except for the general acoustics of the house. The very open design to facilitate air circulation sometimes creates a discomfort when it comes to self-isolation.

Regarding the light, more than the level of lighting, it is the play of reflections on the stainless steel window coverings that contributes a lot to the interior atmosphere.

If you had to do it again?

Two things didn't work in this project. The first concerns the difficulties encountered during modifications on site. The need to make decisions quickly so as not to block progress sometimes leads to choices that lack consistency with the initial project. In this case, it was necessary to pour a screed of 100m2 which was not planned. It was made in concrete whereas a screed of raw earth or lime would have been possible, but only by being planned from the start. The second concerns end-grain flooring materials. The work to be done was very long and complex, and although the result is convincing on the aesthetic level, it is not on the technical level. In the present situation, part of the paving stones have tiled and peeled off from the screed. This is due to insufficient knowledge of the deformations of wood in this type of section.

See more details about this project

https://www.construction21.org/france/articles/h/green-solutions-la-capoeira-une-experimentation-de-deconstruction-et-de-reemploi-des-materiaux-qui-fera-date.htmlPhoto credit

Raphael Fourquemin Architect

Contractor

Construction Manager

Stakeholders

Thermal consultancy agency

FEBUS ECO-HABITAT

CAPDEQUI Yann : yann[a]peyrn.com

Thermal study in the project phase

Company

LE GALL Philippe

philippe.legall[a]riseup.net

https://habitat-eco-action.fr/Training and support for lime and earth plasters

Company

EnergEthic

FRELON Jean-Louis : jl.frelon[a]gmail.com

https://habitat-eco-action.fr/electrical conformity check

Company

SARL Couralet

Franck COURALET (entreprise fermé)

Ground floor cement screed

Company

EURL Larmendieu

http://dartau-platrerie-isolation-arzacq.fr/contact/Ground floor partition

Manufacturer

BROQUART

contact[a]broquart.fr

https://www.broquart.fr/Greenhouse glazing supply

Contracting method

Other methods

Energy consumption

- 134,00 kWhep/m2.an

- 150,00 kWhep/m2.an

- 1,00 kWhep/m2.an

Real final energy consumption

92,30 kWhef/m2.an

92,30 kWhef/m2.an

92,30 kWhef/m2.an

2 019

Envelope performance

- 2,03

- 0,50

More information

The heaviest consumption station is an old generation 150l electric cumulus cloud, over 10 years old, initially installed for the site and planned to be replaced by a solar tank.

Systems

- Wood boiler

- Individual electric boiler

- No cooling system

- Free-cooling

- Humidity sensitive Air Handling Unit (Hygro B

- Wood boiler

- 49,20 %

Smart Building

Urban environment

- 319,00 m2

- 32,00 %

Product

"Rocket" or "Dragon" type mass stove

Conçu par Ianto Evans, Architecte

https://www.rocketstoves.com/contact-2/

https://www.rocketstoves.com/Génie climatique, électricité / Chauffage, eau chaude

Mass stove extremely simple in design, construction and use, with high performance and continuous collaborative development to further improve them.

The project stove is 20cm in diameter, with 7ml of thermal coil distributed between a bench and a wall, all with a mass of about 6t.

No technical survey was carried out on the model of this project, but surveys carried out on stoves of similar design show an efficiency of 80 to 95%.

In this case, a number of clues suggest that the performance is good:

- An outbreak of 1h30 to 2h00 of oak, or 3h00 of coniferous trees, allow radiation over 24h00

- 6 cubic meters allow you to "heat" the whole house, considering that it is not the air that is heated but the thermal mass of the house

- A heating season produces less than 40 liters of "ash" in the form of dust, quite valid as a pigment after rapid grinding.

- No visible smoke escapes from the extraction chimney, only a heat wave.

- The temperature at the outlet of the duct does not exceed 100 ° C

- The vapors are not irritating to the respiratory system in direct inhalation of short duration.

Advantages:

- Very economical to manufacture (600 € here)

- Very simple in design, therefore very accessible

- Easily repairable

- very pleasant to use (easy start, heated bench, stove)

Disadvantages:

- Fire hardly or not visible

- only works well in daily use and in large rooms (infrared)

- requires splitting the wood to a diameter of 6 to 8 cm

A visit to the owner of a similar stove made it possible to better grasp the advantages and disadvantages of the system.

"Pluvalor" integral rainwater recovery system

Conçu par József ORSZÁGH, Ingénieur chimiste

https://www.eautarcie.org/contact.html

https://www.eautarcie.orgAménagement extérieurs / Gestion des eaux pluviales

Quote from the Eautarcie.org website:

"The PLUVALOR system is not a commercially manufactured system, but a concept accessible to all.

A cistern built according to the PLUVALOR principle is the artificial reconstruction of a natural rock cavity in which water is very well preserved.

...

Rainwater collected, stored and filtered according to the PLUVALOR system is suitable for all domestic uses, including and above all for drinking. In general, the quality of the rainwater treated in this way is far superior to that of most distribution water. The systems recommended everywhere have, as a finality, the saving of city water thanks to the use of rainwater. On this point the PLUVALOR system differs from all the others. Without denying the possibility of this saving, the purposes are different:

- Safeguarding the user's health, thanks to the use of chemically non-disinfected water. Children are particularly sensitive to the harmful effects of disinfecting water with chlorine.

- Ensure superior water comfort. The use of non-chlorinated, naturally soft and very pure water makes showers and baths more pleasant. In fresh water cooking food (like beans and meats for example) is easier. The taste of herbal teas, tea, coffee and prepared drinks is much superior.

- Save products for laundry, dishes and cleaning. The absence of excess lime in the rainwater makes the dishes sparkling without any softening product. The total absence of lime deposits prolongs the life of household appliances and taps.

- The full recovery of rainwater reduces the pressure on natural water reserves. The reduction in the quantities of detergents also reduces the pollutant load of the wastewater discharged.

That implies:

- focus on the purpose of collecting rainwater (not to flush the toilet or wash the car)

- To accept the principle of adapting the quality of water to uses, by which we distinguish between water for non-food use and water that is safe to drink.

- To establish the recoverable potential of rainwater. First, we determine the amount of recoverable rainwater, then we size the tank. "

The main brake is psychological in 2 aspects:

- fear of drinking contaminated water, rainwater being perceived as "dirty"

- the difficulty of going to the dry toilet, a logical addition to avoid wasting water.

Construction and exploitation costs

- 600,00 €

- 3 000 €

- 113 446 €

Energy bill

- 1 650,00 €

Reuse : same function or different function

- Structural works

- Structural framework

- Roofing

- Facades

- Locksmithing-Metalwork

- Indoor joineries

- Outdoor joineries

- Floorings

- Partitions

- Isulation

- Electricity

- Heating ventilation air conditioning

- Plumbing

- Landscaping

- others...

Environmental assessment

Social economy

Water management

- 65,00 m3

Indoor Air quality

Comfort

GHG emissions

- 150,00 année(s)

Life Cycle Analysis

Reasons for participating in the competition(s)

Reuse / diversion of in-situ construction materials.

Bio-climatic operation

Renewable energies