Brequigny high school

Last modified by the author on 18/03/2021 - 17:51

Extension + refurbishment

- Building Type : School, college, university

- Construction Year : 1958

- Delivery year : 2020

- Address 1 - street : 7 avenue Georges Graff 35200 RENNES, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 19 580 m2

- Construction/refurbishment cost : 20 000 000 €

- Number of Pupil : 3 500 Pupil

- Cost/m2 : 1021.45 €/m2

-

Primary energy need

43.9 kWhep/m2.an

(Calculation method : RT existant )

This building was awarded the Sustainable Renovation Grand Prize of the Green Solutions Awards 2020-21 at the national level; and a mention for the same category at the international level.

Located in Rennes, the Bréquigny high school has 3,500 students and is the largest high school in Brittany. Built in 1958, its renovation became essential to sustain the reception of students.

The project as a whole concerns:

• the energy renovation of part of the day school and housing buildings

• the rehabilitation with change of use of the current catering building into a foyer, multifunction room, agent pole, professors' space and permanent contracts

• the creation of a new catering center

Egis has established an innovative rehabilitation model that can be reproduced in other educational buildings. A solution that offers an energy level identical to that of a new building, a very low carbon level, a controlled implementation based on the “off-site” technique (see “solutions” tab for the characteristics of this envelope). A solution that guarantees cost and time control on an occupied site, and performance monitoring during the operational phase to guarantee the objectives.

Sustainable development approach of the project owner

Initial training is an essential asset for Brittany in terms of access to employment: the Brittany Region devotes nearly 1/4 of its budget to this. Owner of the Bréquigny high school in Rennes, the largest Breton high school with 3,000 students, the Region is initiating a work program there in 2018 intended to improve the reception and comfort conditions of its users in accordance with axis 1 of its real estate master plan .

It is within this framework that a single contract was awarded to a consortium for the design, construction, operation and maintenance, following a competitive procedure with negotiation lasting 12 months. This global market without allotment led to a saving of time in the realization of the project. The collective carrying over 6 years of performance commitments makes each member of the group accountable.

The main orientations of the client are as follows:

- User health - quality of life inside the establishment

- Energy - design a bioclimatic, efficient building and reduce consumption

- Managing water, waste and green spaces - adapting to your environment

- Reduce the impact of the site on the operation of the site and on the environment

- Eco-management - facilitate upkeep and maintenance

Architectural description

Aesthetic modernization

The aim of the group's project is to develop the influence of the Bréquigny high school by enhancing its image within its neighborhood. Built in 1958 by the architect Louis Arretche, it has undergone multiple changes over the years which have respected the unity of its buildings. The project will keep this continuity and the history of the school by striving to keep a modern and evolving constructive logic.

Low impact linked to the construction site

One of the challenges of this project is the management of the intervention on an occupied site. Indeed, the objective is to avoid the installation of expensive temporary premises and to operate as quickly as possible. In order to achieve this objective, the group has chosen to implement a system of prefabricated modules and industrialized finished products. The modules that make up the facades will be partially clad, insulated and glazed, and will be attached to the existing facade. Then the old windows will be removed and removed and industrialized cladding frames for the interior finish, including blinds, will be installed, room by room.

A protected plant heritage

All the plantations envisaged for the project are adapted to the local climate and require little maintenance. Shaded beds will participate in the atmosphere of undergrowth of the place and the wooded plantations made up of pedunculate oaks, hornbeams and ash trees, will complete the existing wooded frame.

The intervention aims to achieve a significant improvement in operation by adding vertical circulations and heat, by installing insulated and prefabricated caissons allowing intervention on an occupied site.

For each building, a formal metal profile language is developed based on the amplitude of these curves.

Each type is also available in 3 different profiles from commercial products under technical advice:

For building C, north facade, A profiles are used. The amplitude is less; they will catch the light evenly.

For buildings C and A, east and west facades, B profiles are used. The amplitude is greater; the effects of light and shadow are more important and changing throughout the day.

Finally, for building C, a noble facade to the south, the C profiles are used. The amplitude is the greatest; it allows for graphic interplay of radical blacks and whites, and draws a more ornamental facade.

This horizontal shiny metal material is associated with vertical lines of matt metal (zinc). This assembly gives the identity of the facade by reinforcing the perspectives and the play of shadows and light. This dark-looking facade will actually reveal light.

Building users opinion

The thermal and visual comfort is particularly appreciated by the occupants, who quickly forgot the old "thermal strainer" and now have a high school as efficient as a new building.

The air quality has also been reworked, in direct connection with the improvement of the performance of the airtightness of the envelope.

If you had to do it again?

The project is precisely designed to be replicated! As part of the France Relance Plan, the Eco-Energy Tertiary system and more broadly the immense need for thermal and energy renovation of the French building stock, this project is a pilot operation and foreshadows the renovation methods for the years to come.

See more details about this project

https://www.egis.fr/convictions/transition-energetique/lycee-brequigny-un-modele-de-renovation-reproductible-resilienthttps://www.sembreizh.fr/actualites/detail-d-une-actualite/lycees-le-projet-brequigny-en-video.html

https://www.egis.fr/action/actualites/gpni-2020-egis-prix-lycee-brequigny

https://www.groupe-legendre.com/realisation/lycee-de-brequigny-renovation-du-lycee-et-creation-dun-restaurant-scolaire/

Photo credit

Dimitri LAMOUR

Contractor

Construction Manager

Stakeholders

Designer

Anthracite Architecture

Nicolas THEBAULT

http://anthracite-architecture.com/Design + architectural monitoring of works

Construction company

Legendre Construction

Hilaire MENAGE

https://www.groupe-legendre.com/General contractor representative of the group

Company

CCL Constructions

Eric DUBOST

https://www.ccl-construction.fr/Manufacture and installation of timber frame facades

Contractor representative

Sembreizh

Amaury HUET

https://www.sembreizh.fr/Delegated project management

Assistance to the Contracting Authority

ALTEREA

https://www.alterea.fr/Contracting method

Other methods

Energy consumption

- 43,90 kWhep/m2.an

- 88,80 kWhep/m2.an

- 157,00 kWhep/m2.an

Real final energy consumption

37,00 kWhef/m2.an

37,00 kWhef/m2.an

37,00 kWhef/m2.an

2 020

Envelope performance

- 0,56 W.m-2.K-1

- 0,60

- 1,09

More information

Monitoring of consumption according to the IPMVP protocol framed within the framework of a Global Performance Market (MGP). Monitoring is done according to the feedback of meters defined in the metering plan of the IPMVP protocol, with energy report every year.

Systems

- Urban network

- Urban network

- No cooling system

- Single flow

- No renewable energy systems

Smart Building

Urban environment

- 200 000,00 m2

Product

Prefabricated timber frame facade

CCL Construction

Tel : 02 99 76 70 10 / mail : ccl[a]ccl-construction.fr

https://www.ccl-construction.frGros œuvre / Structure, maçonnerie, façade

From the first phases of the studies, the reflections are directed towards a process of mantle walls with wood frame for the insulation of the facades of the buildings, because it is the constructive mode which will make it possible to achieve the primary goal of the project: a significant improvement in the building's energy performance, with a low-carbon construction method, a process that had already been developed a few years earlier during the pilot project for the thermal renovation of Colbert high school in Lorient, a process that can be massively reproduced on other buildings with the same typology. The wooden frame facades, the FOB, are boxes made of a wooden frame, in which is integrated the thermal insulation of the facade, the air and water tightness devices, the exterior joinery, and finally everything that will make the exterior finish of the facade, its architectural side.It is a process that lends itself particularly well to the typology of the building which is the largest high school in Brittany: a great length of building, not very high, very repetitive in its length and characteristic of the constructions of the 1970s in precast concrete. A box corresponds to a storey height, its dimensions allow it to be loaded on standard heavy goods vehicles with a lowered platform, and thus reduce the cost of their transport. Beyond the technical solution, it is also the manufacturing method that been thought out, relying on off-site construction. The major advantage of the FOB is that it is almost entirely manufactured in the workshop, outside the construction site, which makes it possible to limit the nuisances on site, site occupied and in activity throughout the duration of the work, to significantly reduce the on-site response time and the overall duration of the site A short circuit was favored by working with a local company which is close to the site. The FOB model is thought out and designed to be simple, sober and efficient. This simplicity allows, very early in the studies, to concentrate on the development of details and the management of singular points. To do this, the project must be thought through in its implementation: method of fixing the caissons, junction of two juxtaposed caissons, treatment of the angles. It is all these reflections that will lead to an intelligent project according to the DfMA concept - “Design for Manufacturing and Assembly” - “Design for production and assembly”. The mode of grouping of the project in design-construction, in which engineering is associated with the construction company from the genesis of the project, allows the builder to be involved in our reflections. The construction method is thus developed by following the manufacturing processes of the construction company as closely as possible.

All stakeholders were won over by the process, which secures costs, deadlines and quality of execution. The site was carried out in a very unintrusive manner for the occupants, which perfectly met the constraints of the operation's occupied site.

Construction and exploitation costs

- 20 000 000 €

Indoor Air quality

Comfort

GHG emissions

- 7,83 KgCO2/m2/an

- 295,00 KgCO2 /m2

- 50,00 année(s)

- 686,00 KgCO2 /m2

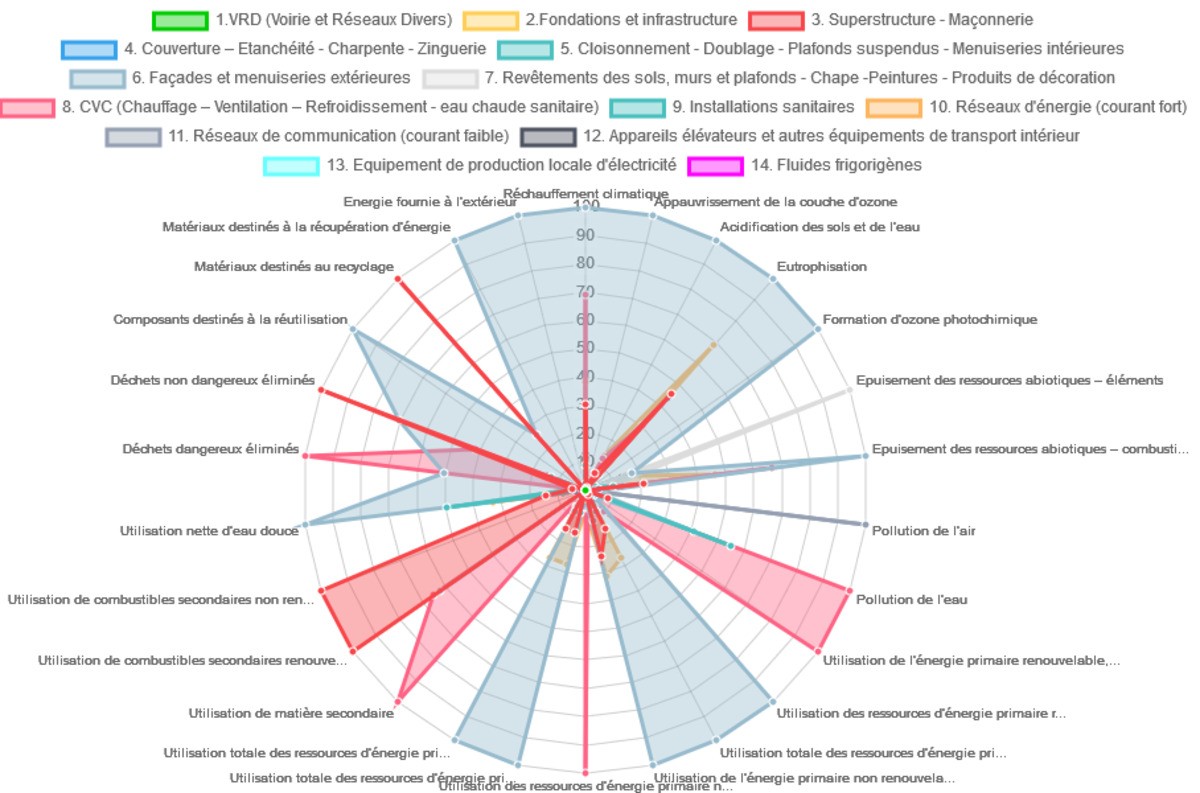

Life Cycle Analysis

- 5 776 340,00 kWhEP

Reasons for participating in the competition(s)

The project responds in a relevant way to many concerns of the current construction sector: ensuring a sustainable character of buildings, guaranteeing reproducibility of the techniques implemented, responding to economic reality at an affordable cost and exploiting the latest innovations to develop the construction sector...

Many themes are thus present in the operation:

- An environmental issue thanks to a low carbon renovation. The level is 409 kgCO2éq / m². A lower level than the construction of a new very low carbon high school (Level C2 of the E + C- label is 750 kgCO2éq / m²).

- An energy challenge by reaching an energy level, after renovation, equivalent to a new building (40.5 kWhEP / m² / year of actual consumption)

- An issue of comfort, health of users, and their involvement in use.

- An issue of quality guarantee, time and cost of construction. The use of off-site prefabrication makes it possible to reduce technical uncertainties, facilitate intervention on an occupied site, and control costs, completion time and quality.

- The challenge of controlling the overall cost of maintenance and operation.

This solution has proven itself in terms of environmental impact. It demonstrated that the renovation of a high school had a less significant impact on the climate than the construction of a new very low carbon high school with the same energy performance.

In 10 months, 10,000 m² of occupied site were renovated, using a unique methodology that can be replicated to most school facilities built over 20 years ago

This model thus represents a real response to the revival of a resilient economy, with the cost of production and operation optimized, and duplicable.