Bike shelter

Last modified by the author on 23/05/2022 - 10:02

New Construction

- Building Type : Other building

- Construction Year : 2022

- Delivery year :

- Address 1 - street : 8 Rue de la Rabotière 44800 SAINT-HERBLAIN, France

- Climate zone : [Cbc] Mild, dry winter, warm and wet summer.

- Net Floor Area : 20 m2

- Construction/refurbishment cost : 18 000 €

- Cost/m2 : 900 €/m2

-

Primary energy need

kWhep/m2.an

(Calculation method : )

Brief presentation of the company 100 Detours, upcycling

The company 100 Détours specializes in the design and manufacture of furniture and architectural devices for interiors and exteriors in wood exclusively from old exterior joinery . Born from the meeting of Benjamin Verger, carpenter, and Jérémie Koempgen, architect-designer, it now integrates Pierrick Soulard, eternal jack of all trades in mechanical production training. The solutions offered range from interior and exterior furniture (constitution of a range of products), glued-laminated trays, acoustic panels, trellises and sunshades, to micro-architecture: garden sheds, bicycles, playground.

100 Détours responds to individuals, businesses, prescribers and public orders.

Our means, our ambition

We seek to find a second life for the wood of old exterior joinery (doors and windows) which, once deposited, are mostly incinerated or buried in France. These woods, with excellent qualities of durability, resistance and aesthetics, actually allow many reuses. We are the second link in a chain following ESIAM, an association for the purpose of employment, which deals with the collection and dismantling of windows in the agglomeration of Bocage Bressuirais in Deux-Sèvres and we offer an outlet for this resource. Our current mission is to invent qualitative works, aesthetically and technically, then our ambition is to participate in the spread of this practice in France by localities and deposits. Indeed, for this project to make sense, many production units of reasonable size must be created in France as close as possible to the deposit which is present throughout the territory.

Honors received :

- Regional award for wood construction 2021 - Pays de la Loire - outdoor development section.

- Regional favorite prize at the Canopée challenge 2022 Nouvelle-Aquitaine.

- Stars and Professions Prize, Responsible category, CMA des Deux Sèvres.

Architectural note

The bike shelter is designed as a space that rhymes with nature . Its frame is made of upcycled glued laminated. The perforated cladding, as well as the bike racks are also made of wood from old exterior carpentry. We worked on the framework as a 3D assembly of small section parts. The optimization of the sections of the pieces, with the help of Vivier Structure Bois, allowed us to obtain this light design, slightly reminiscent of art nouveau and the structures of Hector Guimard's canopies.

Environmental approach

What better program than a bike shelter, the frugal mode of travel par excellence, to push our intervention limits a little further. Reuse and re-use are starting to make headlines on clothing, cladding, decking or interior linings. We wanted to go further and get down to the manufacture of outdoor glued-laminated wooden beams, using our resource of wood from outdoor joinery, and constitute the frame of this bicycle shelter .

Technical description of the layout

It is a bicycle shelter 6.50 m long by 2.91 m wide by 2.54 m high, capable of accommodating 6 bicycle racks (12 bicycles). It is modular, extendable by modules of 3 m. It consists of three porticoes supporting the half cantilevered roof. The posts are made up of 4 pieces of 40x40 mm, the webs of the lattice girders have sections varying between 40x80 mm to 40x140 mm. The bike racks are 70x200 mm in section. Everything is placed on custom-made galvanized steel plates. The cover is made of alveolar polycarbonate and an overlay of wooden slats.

Building users opinion

Customers have repeatedly expressed their satisfaction with the bike shelter. Below is the comment sent by the president of the company:

Post Anne Brochard:

Beautiful as a bike shelter

Exactly a year after we moved in, we finally have our bike shelter. Well deserved and hard sourced. Really.

After having studied more than a dozen solutions (how many bicycles, supplied with electricity or not, metal, plastic or metal .. metal ????????, types of attachment, etc.),

Adjusted the budget twice by complaining about the (sometimes crazy) amounts announced,

I came across 100 Détours… which didn’t have a bike shelter.

100 Détours is co-directed by Benjamin Verger and Jérémie Koempgen

Their thing? Design and manufacture indoor and outdoor furniture in upcycled wood (understand "from the recovery of outdoor joinery"), manufactured in their workshop in Deux-Sèvres.

And therefore the possibility of designing a bike shelter entirely in wood made locally by such good people.

Our beautiful bike shelter is their first bike shelter.

The first shelter in a long series, I can feel it!

Yes really it is very integrated into the space. Can't wait to see it every morning!

If you had to do it again?

Following this first copy of the bicycle shelter, a report sheet was drawn up, among the points mentioned, to be improved later: - The polycarbonate plates will be replaced by stadip glass plates. A search for partnership is being studied with Articonnex on this subject, in order to use reusable lenses. A second thin green roof alternative is also being studied. - Subsequently, the entire structure as well as the laths will be prefabricated so that they can be shipped, then installed by a moderately competent team.

See more details about this project

https://www.100detours.com/abri-a-velos-et-ranges-velos/https://www.panoramabois.fr/projets/7150?participations%5B0%5D=14

https://drive.google.com/open?id=19wJjbXfORor580EXJSfc_hfGUFG2XWMV&authuser=jkoempgen%40gmail.com&usp=drive_fs

https://www.construction21.org/france/articles/h/green-solutions-un-abri-a-velo-surcycle-dans-les-pays-de-la-loire.html?n=20230510085014

Photo credit

Photos 100 Detours

Contractor

Construction Manager

Stakeholders

Company

100 Détours

Benjamin Verger - benjamin[a]100detours.com

https://www.100detours.comCarpentry - Joinery

Structures calculist

Vivier Structures Bois

Maxime Vivier - mvivier[a]vsbois.com - 06.71.38.86.16

https://vsbois.com/Wooden structure design office

Contracting method

Lump-sum turnkey

Energy consumption

More information

None / Outdoor shelter without consumption.

Systems

- No heating system

- No domestic hot water system

- No cooling system

- Double flow

- No renewable energy systems

Urban environment

- 2 620,00 m2

- 19,50 %

Product

100 Détours

info[a]100detours.com

http://www.100detours.com/Gros œuvre / Charpente, couverture, étanchéité

100 Détours

info[a]100detours.com

http://www.100detours.comGénie climatique, électricité / Chauffage, eau chaude

Construction and exploitation costs

- 18 000 €

Reuse : same function or different function

- Structural framework

- Roofing

- Facades

- Landscaping

- The timber of timber frames

- The wooden overlay of the cover

- The facade

- The wood of the bike terminals

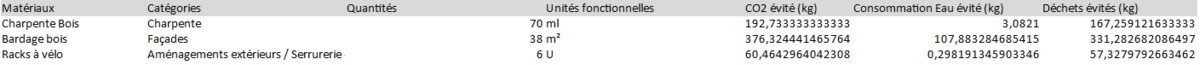

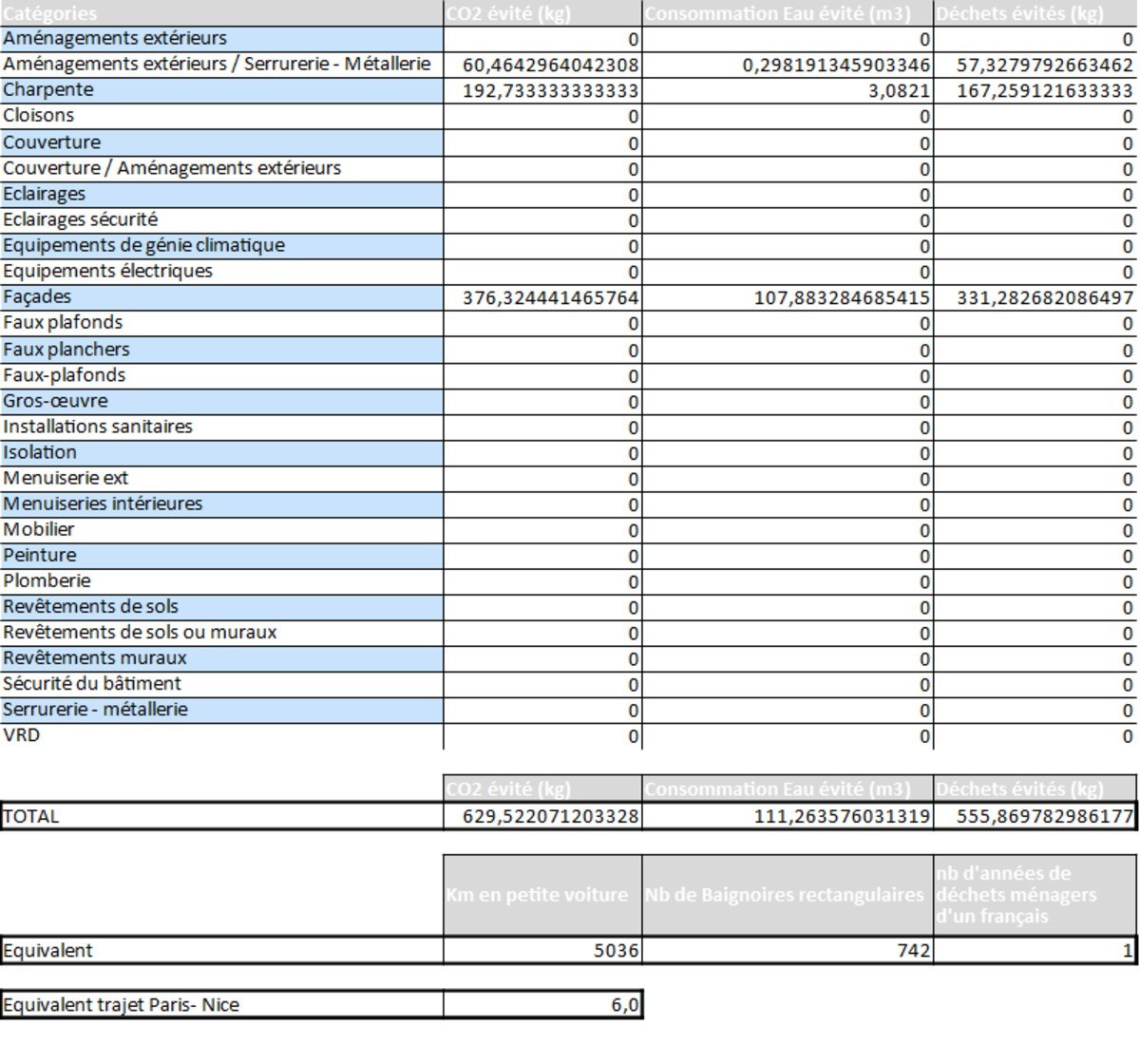

Environmental assessment

Economic assessment

- 17 203 €

- 96 %

Social economy

GHG emissions

Reasons for participating in the competition(s)

What better program than a bike shelter, the frugal mode of travel par excellence, to push our intervention limits a little further. Reuse and re-use are starting to make headlines on clothing, cladding, decking or interior linings. We wanted to go further and tackle the manufacture of outdoor glued-laminated wooden beams, using our resource of wood from outdoor joinery, and constitute the frame of this bicycle shelter.

The candidacy for the Circular Buildings Trophies 2022 is an opportunity for us to highlight the interest of reusing wood from exterior joinery, in terms of carbon footprint, but also to show the mixed aesthetics as well as the quality of the atmosphere. and use, which is induced by the specific constraints of the material.

Finally, the shelter is designed in a modular way, in sections of 3 m, it can be duplicated industrially.

Building candidate in the category