Presentation of the climatic test chamber in ESITC Caen

Create a subpage- Alexia ROBIN

- /

- the 01-02-2019

- / 1081

The SB&WRC project is supported by the European program Interreg VA France (Channel) England and receives financial support from the ERDF.

|

|

|

1.1. Thermal properties

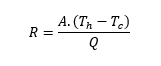

To determine the thermal properties of a building material on a real scale, a Hot Box apparatus is often used. With this apparatus, a wall to be tested is positioned between two ambiences, one hot, and the other cold. Once the steady state is reached, measurement of the heat dissipated to keep a constant temperature gradient through the specimen wall is performed. Thanks to these data, dissipated power and temperature difference between the two atmospheres, thermal performance of the wall can be calculated. So, the prototype thermal resistance can be determined by using the following relationship:

Where:

|

prototype overall thermal resistance, m2.K/W |

|

|

metering box opening area, m2 |

|

Environmental temperature at the hot side (metering chamber), °C |

|

Environmental temperature at the cold side (climatic chamber), °C |

|

rate of heat flow throw the prototype to be tested, W. |

Once the prototype thermal resistance is known, an effective thermal conductivity can be calculated using the following relationship:

- λ: prototype effective thermal conductivity, W/(m.K)

- L: prototype thickness, m

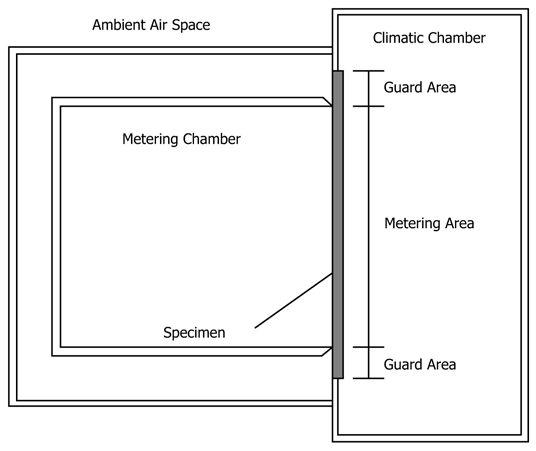

In this project, the thermal performance of the prototype 2 (polyester + OSB) will be studied. To do this, a measuring system is developed by following the ASTM C1363-11 and NF EN ISO 8990 norms. In Figure 3, a typical scheme of a Hot Box apparatus is shown.

Figure 3. Typical Hot Box apparatus schematic [ASTM C1363]

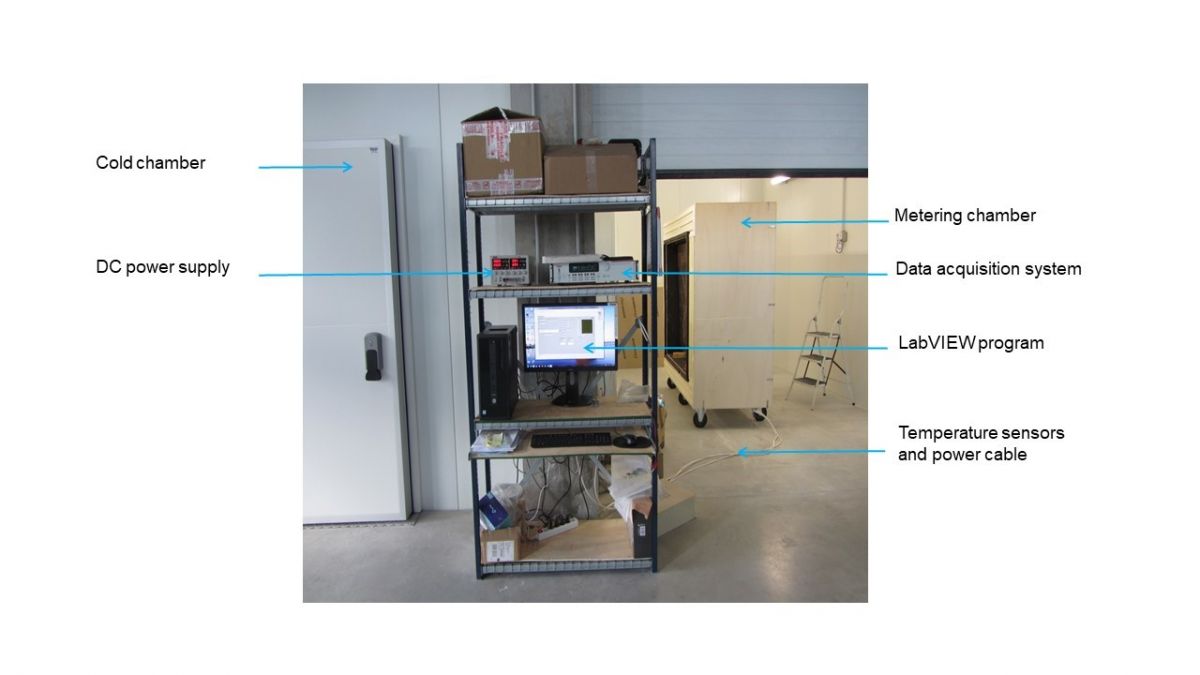

Our measuring system consists of two climatic chambers separated by a polyurethane wall. The separating wall contain a 2 m x 2 m opening where the sample to characterize should be placed. A metering chamber having an opening of 1.27 m x 1.46 m was built. A heating system was placed inside this metering chamber and powered by a DC power supply. Temperatures in both sides of the wall are measured by T type thermocouples which are linked to a data acquisition system. A LabVIEW program was created in a computer in order to perform temperature regulation, data acquisition and signal processing. An overview of the experimental setup is represented in Figure 4.

Figure 4. Overview of the experimental device used for thermal characterization of the prototype 2.