Green Building Industrial Park of China Construction Science and Technology Chengdu (Phase I) - Industrialization Research and Development Center

Last modified by the author on 24/03/2021 - 08:41

New Construction

- Building Type : Office building < 28m

- Construction Year : 2016

- Delivery year : 2018

- Address 1 - street : 天府新区成都直管区新兴工业园区内 610213 成都市, 中国

- Climate zone : [Dfb] Humid Continental Mild Summer, Wet All Year

- Net Floor Area : 4 410 m2

- Construction/refurbishment cost : 35 270 000 ¥

- Number of Work station : 200 Work station

- Cost/m2 : 7997.73 ¥/ m 2

-

Primary energy need

101.3 kWhpe/m2.年

(Calculation method : Primary energy needs )

The project is located in the Xinxing Industrial Park of Tianfu New Area Subsection directly governed by Chengdu, which is outside the high-speed beltway in the southeast corner of Chengdu. The project includes many functions such as office research and development, apartment catering facilities, technology showcase, etc. It is the first ultra-low energy building project in China with the prefabricated concrete structure, adopting technologies related to “Four Savings and One Environmental Protection” which include but are not limited to:

Safe and durable. The project is a building project with the precast concrete structure. The office building is equipped with a monolithic precast con-crete frame structure system, and the apartment building is equipped with a monolithic precast con-crete shear wall structure system, with an assembly rate of 88%. For the first time, through research and development, the exterior walls of the office building have adopted lightweight concrete composite microporous “insulation composite wall structure system” that integrates envelope, decoration, energy saving and fire prevention functions. The external walls of the apartment building adopt precast concrete sandwich facade panel that integrates envelope, decoration, energy saving and fire prevention functions. The new system meets the thermal requirements of ultra-low energy consumption buildings, and is more reliable, safer and more durable than the traditional envelope structure system in terms of the quality. BIM technology is used for design and construction. High-strength reinforcing steel bar above Q345 and HRB400 grades are used in the section of building materials.

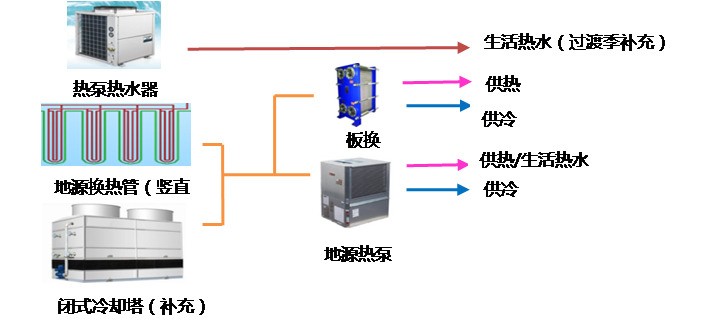

Resource saving. Chengdu is a hot summer and cold winter area with high temperatures and high humidity in summer as well as coldness and dampness in winter. To achieve the goals of comfortable indoor environment and ultra-low energy consumption, this project innovatively proposed the solution of ultra-low energy building technology suitable for hot summer and cold winter areas and put forward a comprehensive solution of no hot and cold bridge, high air tightness and thermal insulation for prefabricated buildings in hot summer and cold winter areas. Meanwhile, a new high reliability and high durability waterproof steam isolation solution was put forward in the indoor project. The exterior windows of the southwest-facing facade of the project were all set with louvers to adjust external sunshade which could improve indoor thermal comfort and control indoor dazzle. The cold energy source adopted the ground source heat pump system with buried pipe type and the assembled machine room to realize heating and cooling, as well as the free cooling function of the cooling tower. Natural lighting was fully used, and window-wall ratio was set reasonably, with 12 light guide pipes set up in the exhibition hall to improve indoor lighting. Under the conditions of meeting dazzle limitation and light distribution requirements, lamps with high efficiency were selected for indoor lighting, and the lighting power density values of each area meet the target value requirements.

Healthy and comfortable. Indoor environment objectives were set by referring to the “Technical Guidelines for Passive Ultra-low Energy Green Buildings (Trial)”. Independent temperature and humidity control was adopted in the air conditioning system to achieve indoor comfort. Ion waterfall technology was adopted to achieve an air purification efficiency of more than 99%. The efficient enclosure structure ensured that the inner surface of the enclosure structure is free of condensation, mildew and moisture condensation, and the indoor temperature field is uniform. The air tightness of the envelope structure was good, resulting in low noise. Through calculation, the indoor noise of the three-storied office building was 36.6dBA when the windows were closed.

Data reliability

3rd part certified

Photo credit

China Construction Science and Technology Group Co., Ltd.

China Southwest Architectural Design And Research Institute Co., Ltd.

China Construction Science and Technology ChengDu Co., Ltd.

Contractor

Construction Manager

Owner approach of sustainability

This project attempts to explore the development direction of future buildings by integrating four technical systems of prefabricated buildings, ultra-low energy buildings, green buildings and intelligent buildings. It is the first ultra-low energy public building project with the prefabricated concrete structure in China and is the demonstration project of the national key R&D plan for the "13th Five-Year Plan" period. This project has obtained the “Sino-German Cooperative High Energy Efficient Buildings-Passive Low Energy Building Quality Label" jointly issued by the Ministry of Housing and Urban-Rural Development of China and German Energy Agency and the three-star green building design label.

From the dimension of green construction, this project has realized the standardization design, factory production, assembly construction, integrated decoration and information-based management. This project adopts green construction approaches such as prefabricated construction and prefabricated decoration. With the application of precast concrete facade panel, concrete composite slabs with lattice girders , precast stairs and precast columns, the assembly rate reaches over 60%, resulting in less use of building materials and less energy consumption of equipment in the construction phase. From the dimension of green building performance, the project follows the basic principles of green building and passive construction, adopting technical measures such as high-performance transparent enclosure structure with heat preservation and heat insulation, high performance system of outside doors and windows, envelope thermal bridge treatment technology, high air tightness technology, high efficiency air heat recovery systems and renewable energy use. A variety of innovative and advanced energy saving technologies are integrated to create a healthy and comfortable indoor environment. The project will become a benchmark for high-quality and energy-efficient buildings and play an exemplary role in the application and promotion of prefabricated buildings and ultra-low energy buildings.

Architectural description

This project puts forward the technical solution of ultra-low energy consumption buildings for hot summer and cold winter areas. One goal of the project is to reduce resource consumption during the building construction and operation while creating a healthy and comfortable indoor environment, which includes: 1) Appropriate temperatures, 20-26 ℃, compatible with human needs, so as to stay away from air conditioning-related diseases; 2) Appropriate humidity, 30%~60%, no indoor dew and mildew, no dry skin in four seasons, no breeding and transmission of bacteria and viruses; 3) Fresh air, CO2 ≤ 1000PPM, reducing the risk of allergies and respiratory diseases; 4) More quietness, noise level ≤ 40DBA in the day and ≤ 30DBA at night, which is conducive to sleep and improving work efficiency. While the indoor environment requirement is met, the energy saving rate of this project reaches over 80%.

The office building and the apartment building of this project respectively adopt frame structure and shear wall structure. The project also puts forward the integrated solution of no hot and cold bridge, high air tightness and heat preservation and insulation in the prefabricated buildings in hot summer and cold winter areas, and proposes the indoor waterproof and steam insulation solution, adopting new waterproof and steam insulation materials with high reliability and durability.

This project adopts the prefabricated cold and heat source station supporting prefabricated buildings. The assembly machine room is divided into module units according to functions. Based on BIM technology, corresponding equipment and piping fittings are integrated around the main machine, with the heat pump host at the core. In addition, each module unit should have a certain ductility to ensure installation space and future maintenance space.

This project adopts several green technologies, including composite ventilation, optical pipes, etc., and strives to achieve excellence in meeting the requirements of “Four Savings and One Environmental Protection”.

If you had to do it again?

Previously, some problems occurred, e.g., on-site construction time was extended and follow-up operation and maintenance was not in place, due to application of more new technologies and new products and fewer personnel who could understand on-site construction operation as well as later operation and maintenance, nevertheless, all the problems have been settled through on-site training and guidance provided by design and technical professionals.

Building users opinion

This project was completed and passed acceptance in December 2018. So far, the indoor air temperature of function rooms such as offices, exhibition halls, multi-function halls, restaurants, etc. can meet the comfortable temperature requirements. The temperatures of vestibular are appropriate in winters and summers. Ground source heat pump system and office air heat recovery system are running normally, which have reduced the operation cost effectively. The energy consumption of air conditioning has been greatly reduced thanks to the integrated design, installation and operation management of heat and cold sources. Since it was put into use, the HVAC system has been operating normally and in good condition, meeting the demand for working, meeting, exhibition, etc. The light pipe system is adopted in the exhibition hall and the lecture hall on the first floor, which contributes greatly to improving the light environment of the section. Efficient envelope structure and excellent air tightness ensure the excellent sound environment of the project, basically not affected by the production noise from the adjacent prefabricated plant.

Energy consumption

- 101,30 kWhpe/m2.年

- 208,00 kWhpe/m2.年

- 40,90 kWhfe/m2.年

Envelope performance

- 0,34 W.m-2.K-1

- 0,39

- 0,51

Real final energy consumption

32,76 kWhfe/m2.年

2 019

Systems

- Geothermal heat pump

- Fan coil

- Heat pump

- Geothermal heat pump

- Fan coil

- Radiant ceiling

- Natural ventilation

- Double flow heat exchanger

- Canadian well

- Heat pump (geothermal)

- 9,36 %

Smart Building

Urban environment

(1) Public transportation

The transportation of this project is very convenient. There is a bus stop at 654m walking distance from the entrance and exit of the project, which is Xinxing Industrial Park Station with Bus 573 and Bus t36. There is a pedestrian passage between the main entrance and exit of the project and the bus station. In line with the principle of rational allocation of resources and good logistics support for employees, a small shuttle bus will be arranged, running between Lianshanpo Metro Station and the company from 8:15 am to 6:15 pm. The bus type is Jinbei commercial bus.

(2) Public services and activities

This project has an exhibition hall of about 560m2 on the first floor, and a meeting room of 100m2. There is also a process model room on the project site, which gives a detailed description of the project's prefabricated ultra-low energy consumption design, construction and operation. In line with the principle of sharing experience and open communication with educational and research institutions from all walks of life, the exhibition hall, the process model room, and the large meeting room on the first floor are open to the public. Schools, associations, and groups are welcome to make phone calls to schedule a visit or a small seminar. The project has successfully carried out twice "China Ultra-low/Near-Zero Energy Building Public Day" activities organized by the passive ultra-low energy building branch of China Association of Building Energy Efficiency, and the Sino-German energy efficiency improvement technology and application demonstration exchange activity jointly organized by China’s Ministry of Housing and Urban-Rural Development and the Industrial Development Center as well as German Energy Agency.

(3) Green environment

1) Ecology and landscape

In combination with the current site situation, the project plans to create a garden-like landscape environment, and grow plants that adapt to the local climate and soil conditions, e.g., a combination of trees, shrubs and grass, and non-toxic and easy-to-maintain native plants suitable for the southwestern region, such as camphor, begonia, etc.

2) No light pollution in architectural and lighting design

Located in Xinxing Industrial Park, Tianfu New Area, the project is adjacent to no residential buildings in the surrounding area. There is no glass curtain wall in the project, and the visible light reflection ratio of the external windows is 0.15. In lighting design, high pole lights are used next to the office building, with lampshades and reduced lighting power. Simple night scene lighting is designed to ensure night safety, and causes no light pollution to buildings nearby.

3) Wind environment

Through simulated calculations, under the conditions of typical wind speed and wind direction in winter, the maximum wind speed at 1.5m from the ground in the pedestrian area around the building is 2.0m/s, the average wind speed is 1.0m/s, and the wind speed amplification factor is 1.62. Except for the first row of buildings facing the wind, the maximum wind pressure difference between the windward side and the leeward side of the building is 2.3Pa. Under the conditions of typical wind speed and wind direction in transition seasons and summer, there will be no vortex and windless area in the human activity area in the project. In terms of the external windows, the area ratio of the openable external windows where the indoor-outdoor surface wind pressure difference is greater than 0.5Pa reaches 83.14%.

4) Acoustic environment

Noise will come from the factory in the industrial park when mixers, conveyors, transport vehicles, water pumps, straighteners, bending machines, shears and other equipment are in operation. After noise reduction measures are taken such as reasonable general layout, vibration reduction, sound insulation, and noise reduction, the operating noise within the factory boundary can meet the Category 3 requirements of "Emission Standard for Industrial Enterprises Noise at Boundary". A distance between the R&D center and the factory building will also reduce a certain amount of noise. In addition, good air tightness and sound insulation performance of the R&D center’s outer windows and outer building enclosures also contribute largely to the reduction of noise interference.

Land plot area

6 751,60 m2

Green space

26 890,40

Parking spaces

There are 87 parking spaces for motor vehicles on the south and west sides of the project, and 100 parking spaces for non-motor vehicles near the dormitory of the shift building, with protective measures against wind and rain.

Product

Building airtight materials

北京中核北研科技发展股份有限公司

http://www.bjzhby.com/

sealing material

LEAC acrylic polymer cement waterproof coating is a two-component waterproof coating composed of special waterproof acrylic polymer emulsion and special powder. The product is an acrylic polymer product, without plasticizers and film-forming additives, and has excellent water resistance and weather resistance. Its advantages are: water-based environmentally friendly products, no lap joints after completion of construction, full-adhesive materials, good weather resistance, strong freeze-thaw resistance, good UV aging resistance, suitable for all building climate areas in the country, good water resistance, good elasticity, cold coating of water-based materials, and strong adhesion or adhesion with common building materials.

Fabric air supply system

织物空气(青岛)科技有限公司

http://www.fabricair.cnHVAC、电 / 通风、制冷

HVAC system

A kind of flexible air distribution system woven from special fibers, the fabric air supply system is mainly used to replace traditional air supply pipes, air valves, diffusers and other air supply systems, and has been widely and flexibly applied in a variety of spaces, such as commercial places, sports venues, food production places like food factories, supermarkets and other business places. It can be directly connected to the outlet of fan equipment, or can be connected to iron ducts and composite ducts. The air supply system can be arranged according to the actual situation of the air supply site. Its advantages include no blowing feeling, uniform air supply, anti-condensation, easy cleaning and maintenance, light weight, quiet operation, simple and flexible installation.

light pipes

威卢克斯(中国)有限公司

http://www.velux.com.cn/index.htmlHVAC、电 / 照明

Lighting equipment

VELUX's patented SunCurve solar collector captures sunlight and blocks ultraviolet rays. It has high-efficiency Miro Silver mirror reflection with a reflectivity of up to 99%. It is coated in a vacuum environment and has a longer life. Multi-layer protective film can effectively prevent falling off and corrosion. Excellent diffusion effect maximizes the lighting coverage area. A variety of lighting methods are available to present a variety of interior effects.

Vacuum insulation board

中亨新型材料科技有限公司

http://www.vokesi.com/

Insulation Materials

HVIP aerogel vacuum insulation board is a core material containing many nano-voids (aerogel fumed silica, a nano-porous material with an average particle size of 10-20nm) insulation board, encapsulated in a high barrier film, and then manufactured through a vacuum process. It is characterized by good thermal insulation performance, safe fire performance (A grade), good system stability, thin thermal insulation system, long service life, energy saving and environmental protection.

Construction and exploitation costs

- 5 520 000 ¥

- 35 270 000 ¥

Energy bill

- 225 700,00 ¥

Building Environmental Quality

- Building flexibility

- indoor air quality and health

- renewable energies

- integration in the land

- mobility

- products and materials

Water management

- 2 033,66 m3

- 104,58 m3

Indoor Air quality

Comfort

GHG emissions

- 25,40 KgCO2/m2/年

- 25,89 KgCO2 /m2

- 50,00 年

Reasons for participating in the competition(s)

(1) Occupants’ well-being

By creating a beautiful green indoor environment, a comfortable indoor environment with moderate temperatures and humidity, a good indoor air quality, as well as a healthy sound and light environment, the project makes a high-quality office and rest environment for employees, who can thus work more efficiently and have a higher sense of achievement and happiness.

(2) Economic benefits

Many new technologies, new materials, and new products such as high-performance thermal insulation system, door and window system and energy environment system are adopted in the project to realize the ultra-low energy consumption of buildings. The construction is carried out in accordance with multiple guidelines and unified standards for efficient and orderly operation of the demonstration project. The heating and air-conditioning energy consumption is greatly reduced during the operation process, thereby reducing the operating cost of the project. With the annual heating, ventilation and air-conditioning power consumption of the buildings kept within 20kWh/m2, significant economic benefits have been realized in the project.

(3) Social benefits

The project has achieved the goal of prefabricated ultra-low energy buildings by fully considering the technical and economic rationality in design, and adopting reasonable planning, architectural design and technical measures. By applying the concept of "adapting measures to local conditions" central to the green building design, the project has also realized the goal of energy saving, emission reduction and environmental protection, playing a very good role in publicity and promotion of ultra-low energy building technology in hot summer and cold winter areas.

(4) Environmental benefits

In the building designing, the project uses passive green innovation technology to achieve the low-carbon goal of the building, and minimizes the use of fossil energy to reduce the emission of harmful gases, smoke and dust, improve the air quality, and lessen the impact of pollutants and greenhouse gases generated within the life cycle on the surrounding areas, which is in conformity with the green development concept of urbanization and has achieved significant environmental benefits.