Neobuild Innovation Centre

Last modified by the author on 09/06/2015 - 17:18

New Construction

- Building Type : Office building < 28m

- Construction Year : 2013

- Delivery year : 2014

- Address 1 - street : ZAE Krakelshaff, 5A L-3290 BETTEMBOURG, Luxembourg

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 1 420 m2

- Construction/refurbishment cost : 5 000 000 €

- Number of Work station : 140 Work station

- Cost/m2 : 3521.13 €/m2

-

Primary energy need

46 kWhep/m2.an

(Calculation method : RGD du 31 août 2010 - bâtiment fonctionnel )

The Neobuild Innovation Centre is a ground-breaking and experimentalshowcase building.

Indeed, it heralds the arrival of the 2020 ZeroEnergy Buildings.

This building incorporates a number of the mostinnovative processes and materials in its construction.

In addition, it truly is a Living Lab, where avariety of different materials, products and installations can be tested andmonitored.

Manufacturers can also show off their innovativesolutions in order to test them under real-world operating conditions and getfeedback from users.

Lastly, this building is also a showcase, giventhat it will be used as a life-size resource for providing specific training(e.g. HVAC).

See more details about this project

http://neobuild.lu/nos-services/neobuild-innovation-living-labhttp://www.construction21.org/luxembourg/articles/lu/laureat-batiments-intelligents-2015-neobuild-innovation-center-luxembourg.html

Data reliability

Assessor

Stakeholders

Designer

ARCO

[email protected] - Tél. 42 17 70

http://www.arco.lu/

Milestone Consulting Engineers

[email protected] - Té. 31 61 61 1

http://www.mstconsult.lu/Thermal consultancy agency

COCERT

[email protected] - Tél. 26 59 56 42

http://www.cocert.lu/Other consultancy agency

Siegel Schleimer

[email protected] - Tél. 26 37 87 37

http://www.siegelschleimer.lu/Engineering and Design Department (electricity lot)

Assistance to the Contracting Authority

CIMALUX

[email protected] - Tél. 55 25 25 1

http://www.cimalux.lu/Company

POECKES

Tél. 56 46 36 1

Concrete structural works

Company

Steffen

[email protected] - Tél. 71 96 86 0

http://www.steffen-holzbau.lu/Wooden structural works

Company

a+p Kieffer Omnitec

[email protected] - Tél. 47 48 48 1

http://www.apko.lu/HVAC + Electricity

Company

Servalux

[email protected] - Tél. 26 95 31 81

http://www.servalux.lu/Woodwork

Company

OST

[email protected] - Tél. 71 90 91 1

http://www.ost.lu/Woodwork

Owner approach of sustainability

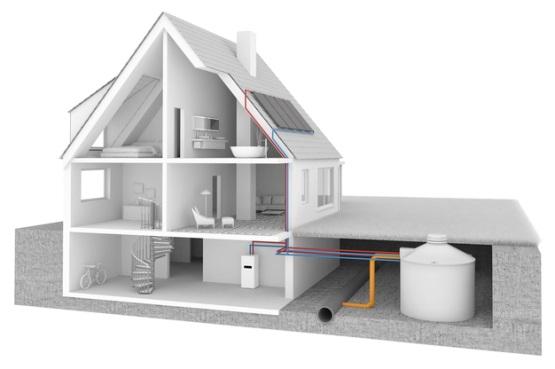

This building very much fits in with the Horizon 2020 initiative set up by the European Commission. In effect, by that date, any new building must be “zero energy”. Neobuild wanted to get a six-year head start on this regulation by constructing a building which heralds the arrival of smart buildings and which will use as much energy as it will generate. To do this, special heating and ventilation systems have been set up, which will be supplied by a number of renewable energy systems (such as solar panels, geothermal energy, ice stores, etc.).

Alongside this purely environmental aspect, a lot of importance has been placed on the comfort of users, an equally vital component. This building will be regularly monitored and its users will play a key participatory role in this, being able to determine the heating or lighting levels, for example.

Finally, the construction techniques are obviously in line with the latest products on the market, or even experimental ones, such as for insulation or for planting roofs and walls.

Architectural description

The Neobuild building is a two-level solid timber structure standing on a concrete lower storey. The 500m2 ground floor is used for the plant rooms, a workshop for training and a meeting space for professionals. The two upper floors comprise offices, training and meeting rooms, with a total floor space of 1,000m2. The flat roofs are used for plant and equipment; they have a useable surface area of 560m2. The new building is connected to the IFSB building (Training Institute for the Construction Industry) by a triangular atrium made from a 3D web of metal beams. For moving between the different entrances to IFSB, Neobuild and the main private entrance to Neobuild from the road there are concrete-coated pan joist floors. The net surface area of this zone is 300m2. The main building is split in two vertically by a glass corridor, creating two staggered units perpendicular to the existing building. On one of these units, the wooden facade is arranged vertically whilst on the other it is horizontal, based on the aspect and exposure to the sun of the units. The external woodwork is fitted with over-sized frames in order to emphasise the volume of wood over the concrete base.

The atrium is partially enclosed at the sides using glass curtain walls in order to highlight the transparency of its role as a connection. Sections have been left vacant for experimental purposes. In order to target a reduction in energy usage and greenhouse gas emissions, innovative environmentally friendly, high-performance products have been used. These products meet the requirements for passive buildings, such as some of the windows which have electrochromic panes of glass. Different types of insulation have been fitted in each of the external walls and their behaviour is monitored using probes.

The building, produced in accordance with "passive" energy requirements, is air-conditioned throughout (heating/ventilation/cooling). In addition, three rooms have new ground-heating systems. The energy is supplied from a number of renewable sources such as geothermal wells, ice stores or bins or simply the outside air. Three heat pumps juggle the different energy sources to test the optimum configuration. Eleven lighting designs were assessed using LED technologies. The power required is less than 10W/m2.

The internal layout has been created by taking account, in part, of the lighting designs and the precise acoustic ratings to be achieved. As a result, a variety of different types of screed, indoor woodwork, false ceilings and acoustic wall panels are used.

The part-planted roof houses the solar panels, the weather station, the urban greenhouses with hydroponic or even aeroponic systems, along with empty spaces for future developments (such as a solar concentrator).

If you had to do it again?

Perhaps plan the project in a more optimal way, in full cooperation with the architect.

In effect, this would have allowed the building to be better designed and its construction could have been planned better, under the keen eye of the architect.

As the building is experimental, choices had to be made in the selection of materials used.

Yet, new materials are being developed constantly.

We are fortunate, therefore, that we can continually evolve the building, able to change this or that material over time.

Building users opinion

As part of a continuous improvement process, Neobuild has issued a satisfaction questionnaire to the occupants of the building and to visitors, in order to gather their views and comments and to assess any potential areas for improvement. These surveys have helped to enhance the level of comfort of the occupants. The results showed that the occupants particularly appreciated the lighting levels (e.g. electrochromic glass), the visible wooden structure which gives Neobuild Innovation Centre a welcoming feel, the roof-top greenhouse and garden, the sports equipment, the user-friendly kitchenettes and the individual control of the lights and the outdoor blinds.

Energy consumption

- 46,00 kWhep/m2.an

- 142,50 kWhep/m2.an

- 17,30 kWhef/m2.an

Envelope performance

- 0,23 W.m-2.K-1

- 0,35

- 0,54

Real final energy consumption

63,00 kWhef/m2.an

2 015

Systems

- Heat pump

- Geothermal heat pump

- Low temperature floor heating

- Fuel cell

- Heat pump

- Geothermal heat pump

- Radiant ceiling

- Double flow heat exchanger

- Solar photovoltaic

- Solar Thermal

- Heat pump

- Fuel cell

- 37,00 %

Smart Building

GHG emissions

- 11,30 KgCO2/m2/an

Life Cycle Analysis

Water management

Comfort

Product

SageGlass dynamic glazing

Buderus

http://www.buderus.luHVAC, électricité / heating, hot water

Window glass with a tint that can be electronically adjusted for new or renovated offices, schools or hospitals, for facades or glass roofs.SageGlass® provides comfort and energy savings by adjusting the its tint and controls the heat and glare of the sun by replacing traditional solutions such as blinds.

This innovative technology allows the glass roof to be retained in full whilst avoiding the need for an air-conditioning system or sunshades which are expensive to purchase and maintain.

Plant Box, by PlantDesign

PLANT DESIGN

Sébastien CREPIEUX - Tel : +32 473 193 323 - Mail : [email protected]

http://www.plantdesign.be/fr/Finishing work / paints, mural, wallcoverings

Made of sphagnum and steel, Plant Box is used to build planted internal and external walls for a range of applications, both aesthetical and architectural.To date, more than 200 planted walls have been erected by the Plant Design company.

Out of the ordinary, this touch of greenery inside the building appeals to many!

Gyproc SoundBlock

Gyproc

Michel LAMBERTS - Tel : +32 495 121 712 - Mail : [email protected]

http://www.gyproc.be/homepage/frFinishing work / paints, mural, wallcoverings

Gyproc SoundBlock has very specific plaster core which ensures a high level of sound insulation.It has been developed in combination with the Metal Stud SoundBlock profiles to offer the highest levels of noise insulation on the marketand it remains a very thin partition.

Activ'Air

Gyproc

Michel LAMBERTS - Tel : +32 495 121 712 - Mail : [email protected]

http://www.gyproc.be/homepage/frFinishing work / paints, mural, wallcoverings

Activ’Air® captures up to 80% of the main Volatile Organic Compounds (VOCs) and converts them into an inert compound.It creates a chemical reaction with formaldehydes and converts them into inert compounds without re-emitting them into the indoor air.Any aldehyde is thereby removed on contact with the Activ’Air® technology.

As air quality is still uncharted territory, this product has been put into service to test its effectiveness.

Enerlin'X Smartlink

Schneider Electric

Frederic Mames - [email protected]

http://www.schneider-electric.fr/fr/product-range/61356-enerlin-x-smartlink/Finishing work / Electrical systems - Low and high current

The core of the Acti 9 Control system, the new modular smart Acti 9 Smartlink interface, sends the data from the Acti 9 devices to an automated controller or a monitoring system, using the Modbus serial line connection network.

All of the data are stored, such as number of cycles, consumption, running time, even in the event of a loss of power.

No configuration is required for the products connected.

The communication adapts automatically, when Acti 9 Smartlink is switched on, to the communication settings of the Modbus master (PLC, monitor).

Although the idea of a Smart Building is very well known in the press and in construction news, getting hold of equipment has not been easy. Schneider Electric has helped to consolidate smart concepts devised during the design stage.

DuPont™ Energain®

Dupont de Nemours Luxembourg

Laurent ZANUSSI - Tel : +32 475 866 861 - Mail : [email protected]

http://energain.fr/Energain/fr_FR/index.htmlFinishing work / Partitions, insulation

DuPont™ Energain® is made of a polymer which contains a phase-change material (PCM) made of paraffin wax.

It means that excess heat in a room can be absorbed when the temperature rises and, conversely, can be returned when the indoor temperature falls.

This product is traditionally placed behind a plasterboard but in the NIC this product has been placed in the ceiling to test its effectiveness in this location. As a result, it has not been the success it deserved.

VELUX modular glass roofs

VELUX

Philippe Walczynski - Tel : +32/476-222307 - Mail : [email protected]

http://www.velux.fr/Finishing work / Exterior joinery - Doors and Windows

A unique design, with new materials with even better energy efficiency.The new modular VELUX glass roofs are a game-changer for the commercial roof glazing market.For the first time, the sector can boast a full pre-fabricated glass roof design.

This glass roof have provided enough light for the planted wall. It is relatively easy to use and install. However, there were restrictions on purchasing it because the minimum size is not the same, depending on the country where the order is placed.

Ice store

Viessmann / Isocal

François Siméon - Tel : +352 661300036 - Mail : [email protected]

http://www.viessmann.lu/HVAC, électricité / heating, hot water

The "ice store" is a buffer store of solar energy, outdoor air, ground energy and other natural resources.By using the latent heat of the water, this system supplies the primary energy required for the heat pump to work throughout the heating season with no well!

This idea, which is as old as time, has re-emerged with precisely-scaled systems. The implementation and optimisation times are quite long. We have not been completely satisfied but it remains a promising product.

Greenskin Box®

Greenskin DVMH

Denis LEJOSNE - Tel : +33 6 46 79 07 21 - Mail : [email protected]

http://www.greenskin.be/Finishing work / flooring

Greenskin DVMH has developed and painted a range of green standardised, pre-assembled "ready to fit" roofs which are modular and customisable. It is a fully modular system, laid on pads which can be fitted on any type of flat or gently sloping roof.

This system is innovative and is absolutely ideal for small spaces. As well as offering additional functionality for the roof, this system adds an economic and social benefit for the building.

ISOTEX

ISOTEX

Yannick VILLEGAS - Tel : +352 661 163 910 - Mail : [email protected]

http://www.isotexfrance.com/Structural work / Structure - Masonry - Facade

Wood-cement construction products, environmentally friendly, blocks and floorings.

To start with, the workers were resistant to this new material because they weren't used to wooden materials. The first two rows which were laid helped them to see that it is similar to fit to concrete blocks and that it was much more comfortable to handle thanks to the wood.

Woobago

cycl'home

Serge Gosset

http://www.cyclhome.com/woobago.htmlFinishing work / Partitions, insulation

Woobago's system and structures use 100% biodegradable raw materials and locally sourced products, with all that this implies in terms of quality and beneficial impact for the social and economic fabric of your region. Furthermore, these raw materials are rapidly renewable: bamboo, indigenous wood, straw and local clay.

As straw is not very widespread in innovative construction, it attracts a lot of curiosity from visitors in the experimental connection area.

Foobot

foobot

Gwen Lasbleiz : [email protected]

http://foobot.io/Finishing work / Indoor facilities

Foobot is a smart online device which can measure air quality in the home.It makes a number of claims: tracking allergy-causing particles, keeping chemical components under control which stem from our mobile devices and controlling the correct temperature and humidity level to create a more pleasant living space for the whole family.

A new arrival on the market, this additional piece of equipment helps to consolidate and cross-check the results obtained using the various different air sensors included in the rooms.

BEN-Q

http://benq.eu/

http://benq.eu/

The solar panels which use back contact technology are made of single-crystal solar cells which are currently considered to be the best technology on the market.These cells have the notable feature of generating a very high load voltage, even in high temperatures and provide an excellent load input even with very low irradiance.

As solar panels are already a well-known product, it was straight-forward to incorporate them.

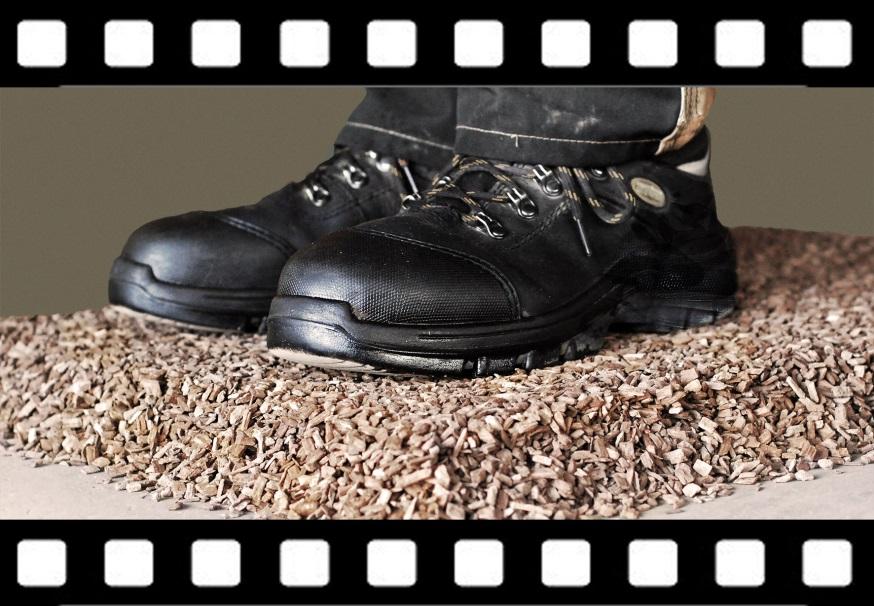

CEMWOOD

CEMWOOD

Carlo Posing - Tel : +352 691 816757 - [email protected]

http://www.cemwood.de/en/Finishing work / Partitions, insulation

CW2000 is a filling made of wood shavings with a mineral coating and defined cubic chip form.The special combination of materials allows the beneficial properties of the wood and mineral substances to be practically combined.

Putting this material into service beneath a screed posed a number of questions for the companies. However, the implementation phase was particularly appreciated by the workers and, after one year in service, the results are still very positive.

SportsArt ECO-POWR™

SportsArt Fitness

Giorgio Gervasoni [email protected]

http://gosportsart.com/Finishing work / Indoor facilities

The SportsArt machines can convert human effort into electricity and return it directly to the network.These 3 machines have been connected in series and can aggregate their generation.As for the power generated, it all depends on the effort.Gently pedalling generates around 30W whereas a fit male athlete at full exertion can generate up to 400W.

An integral part of the gym, this product contributes to the well-being of the company's employees by promoting cohesion within the group.In addition, it generates power for the building, which adds to its energy self-sufficiency. This innovation can find a place with companies that promote technologies which make the building more comfortable and sustainable.

Fuel cell

Saint-Gobain Int. AG

François Pigeolet - Tel : +32 478 495 774 - Mail : [email protected]

http://sageglass.com/fr/Finishing work / Exterior joinery - Doors and Windows

An innovative technology for a single-family house, generating heat and electricity at the same time. At 45%, the efficiency in electricity generation mode is particularly favourable.

The Neobuild platform is fully aligned to demonstrate this new technology as part of the European ene.field projects.

Construction and exploitation costs

- 750 000,00 €

Urban environment

The building is located in the Krakelshaff business park, 500 metres from the Bettembourg railway station. It is served by a bus route between the business park and Bettembourg station. The company's restaurant, located in the basement of the IFSB building, provides catering for staff in the business park.

Land plot area

2 423,00 m2

Built-up area

23,00 %

Green space

120,00

Parking spaces

Car parking is shared with IFSB.

Permeable car park with space for 150 cars.

Building Environmental Quality

- Building flexibility

- indoor air quality and health

- biodiversity

- consultation - cooperation

- acoustics

- comfort (visual, olfactive, thermal)

- waste management (related to activity)

- water management

- energy efficiency

- renewable energies

- maintenance

- integration in the land

Reasons for participating in the competition(s)

Parce qu’il est un véritable laboratoire intégrant plus 100 matériaux, produits et systèmes différents, ce bâtiment de haute technologie « nearly zéro énergie » de 2200 m² impressionne beaucoup. A la fois expérimental et pédagogique, il offre de nombreuses possibilités en matière de monitoring et de tests grandeur nature.

Le Neobuild Innovation Center, en tant que véritable Living Lab, intègre de nombreuses technologies innovantes, telles que le projet Neostein® développé par l’entreprise IMSIM, qui constitue un parcours pédagogique du bâtiment.

C’est un bâtiment vivant évolutif, non seulement en fonction des besoins de ses occupants, des entreprises, qui ont l’opportunité de découvrir et de faire découvrir de nouveaux matériaux ou des technologies innovantes, mais qui progresse également continuellement pour tenter de répondre aux exigences environnementales naturelles et nécessaires.

C’est pour ces raisons que Neobuild Innovation Center est un très bon candidat pour ces quatre catégories.

Matériaux bio-sourcés et recyclés

L’utilisation en majeur partie du bois massif, de la cellulose, du bois-ciment, de granulats de pierre, du bardage bois et d’une peinture 100% bio-sourcés nous positionne favorablement pour défendre l’engagement dans les matériaux bio-sourcés de la grande région.

Energies Renouvelables

Les forages géothermiques, les bacs à glaces, les corbeilles enterrées, les panneaux solaires thermiques présentent diverses sources d’énergies renouvelables pour alimenter les trois pompes à chaleur du bâtiment.Ces dernières sont fournies en électricité par 7 systèmes de panneaux photovoltaïques et le système d’énergie inépuisable par excellence, l’énergie humaine.

Sante & Confort

Le confort des utilisateurs était une des préoccupations principales à l’origine du projet. Pour y répondre au mieux, il a fallu définir le concept de « confort » pour chacun. Suite à quelques interviews,un compromis respectant confort et environnement a été établi. Aujourd’hui,chaque utilisateur bénéficie d’un espace lumineux et fonctionnel tout en acceptant que les chaleurs estivales doivent être gérées par un comportement adapté et non en ayant recours à la climatisation. L’utilisation de matériaux régulant naturellement l’hygrométrie des espaces, une ventilation adaptée et la présence de matériaux inoffensifs tels que les peintures naturelles et les colles sans formaldéhydes, sont autant d’éléments qui prodiguent un air sain aux utilisateurs. Celui-ci est contrôlé par de multiples capteurs qui alarment le gestionnaire en cas de déviance. En parallèle de ce contrôle, des enquêtes de satisfactions sont menées régulièrement afin de répondre aux besoins des utilisateurs en constante évolution.

Smart Buildings

La présence de plus de 1500 capteurs à multiples fonction permettent un monitoring rigoureux du bâtiment et de ses installations techniques afin d’être en adéquation parfaite avec les fonctionnalités premières du bâtiment. De plus, les technologies misent en place permettent la réalisation d’un délestage de premier niveau. L’aspect « Smart » du bâtiment est également soutenu par des utilisateurs avertis qui intègrent aisément le concept et qui se veulent actifs dans son évolution.

Building candidate in the category

Bio-based Materials

Renewable energies

Smart Buildings