"Antonio Brancati" Middle School

Last modified by the author on 26/03/2021 - 16:21

New Construction

- Building Type : School, college, university

- Construction Year : 2018

- Delivery year : 2020

- Address 1 - street : Lamarmora 61122 PESARO, Italy

- Climate zone : [Csb] Coastal Mediterranean - Mild with cool, dry summer.

- Net Floor Area : 2 430 m2

- Construction/refurbishment cost : 3 175 579 €

- Number of Pupil : 375 Pupil

- Cost/m2 : 1306.82 €/m2

Certifications :

-

Primary energy need

26.8 kWhpe/m2.year

(Calculation method : UNI TS 11300 )

This building was awarded the Energy & Temperate Climates Prize at the international level and a mention for the Sustainable Construction Grand Prize at the national level of the Green Solutions Awards 2020-21.

The new secondary school “Antonio Brancati” in Pesaro (Italy) got three first:

- The highest scoring “Schools” energy environmental certification in Europe;

- The third highest scoring “Schools” energy environmental certification in the world out of 1,733 certifications in LEED system;

- The highest scoring v4 “Schools” certification in the world.

This is a new school built on an abandoned urban area and it has a very important role also in terms of social sustainability, not only as an excellent green building.

Since the beginning, the decision of the municipality was made to reuse the site for a school with zero land consumption by redeveloping the abandoned urban area, and replacing three old army barracks built in 1950 with the new middle-school.

This school building excellence is the result of the ambitious commitment of Pesaro municipality to preserve the environment and tackle climate change. The City of Pesaro has refocused the mandate of local construction on efficiency, sustainability, and responsibility.

In 2017, the City of Pesaro launched a pilot project with the aim of encouraging a holistic approach towards circular economy principles to ensure the building design responds to environmental protection, health and well-being and other social considerations.

The ambition of Pesaro City is to accelerate the transition towards a circular economy, enabling construction firms to use a new system beyond the current outdated ‘take-make-dispose’ model and contribute to mainstreaming the circular economy concept within and outside the city.

Instead of taking a traditional approach to developing works procurement, the city decided to adopt a more circular approach which would be to build a sustainable new school using the current asset.

The intent was to optimise circularity and enhance the use of sustainable building material and technologies, save raw materials, and minimise waste from the construction of the building.

The analysis of not only educational needs but also citizens expectations for use was the central theme: to make the building more circular in terms of its functionality and make sure that it can be used by everyone all day, every day to become a wonderful community space for all the citizens.

The call for tender describes technical specifications and provides measurable requirements against which the tenders can be evaluated. Performance-based criteria describe the expected results and which outputs are mandatory. In the case of this project, two criteria were selected as mandatory: (a) obtaining a nZEB school and (b) providing the environmental energy certification using the LEED certification scheme, achieving at minimum, the LEED Gold certification.

As a result, the tender includes technical specification on energy efficiency, product lifecycle, waste management, water efficiency, with attention paid to internal comfort to create the best indoor environmental conditions for the students and teachers. It is relevant not only the energy consumption reduction but also the indoor quality for the students and staff through acoustics, air quality and thermal comfort requirements. These results are guaranteed by the LEED environmental energy certification made mandatory in the tender notice obtaining the LEED v4BD+C with the score of 88 points.

The project is successful because it achieves the goal of a building that is extraordinary in every sustainable LEED evaluation area and the records achieved are the confirmation of this. The tendering process can be replicated by other municipalities to obtain not only energy efficiency buildings but above all to reduce the buildings’ carbon footprint.

This project provides the first concrete example in mainstreaming circular practices in public procurement. The innovativeness of this project is to take into practice circular principles within the public procurement and ensure that the procedure runs efficiently and obtains the expected results based on environmental and social requirements.

This project also demonstrates that the Green Public Procurement process where environmental requirements are made mandatory within the tendering process using predetermined award criteria is essential for delivering environmental social value, influencing the market towards sustainable materials and products, improving new skills on green jobs.

School requirements achieved:

Low impact school:

- construction and demolition waste management, and also waste management during the construction phase;

- zero land consumption;

- EPD material labelling.

Waste management:

During all the process 556,630 kg of waste were created and thanks to all material flows monitored 546,378 kg was recycled and recovered achieving a 98% recovered waste. The school is also equipped with separate collection bins for paper, metal, plastic and glass.

Architectural design:

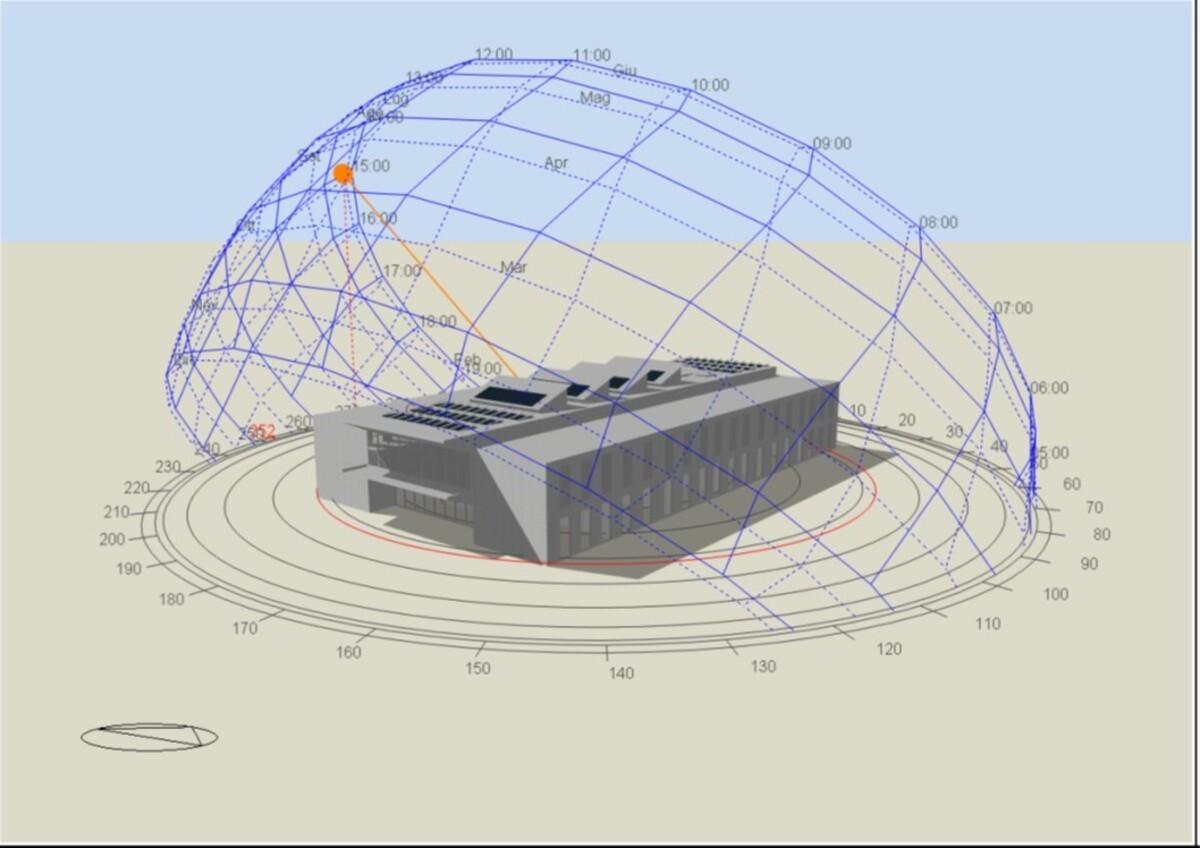

The shape and position of the building was studied and orientated to best exploit solar radiation and optimize the free solar gains and natural lighting and shading;

Due to the mooth tone-in-tone colours of the facade, the building is harmonious within the context creating a friendly new space for all the citizens.

Labeling:

LEED Platinum with 88 points – nZEB standard

Comfort for all:

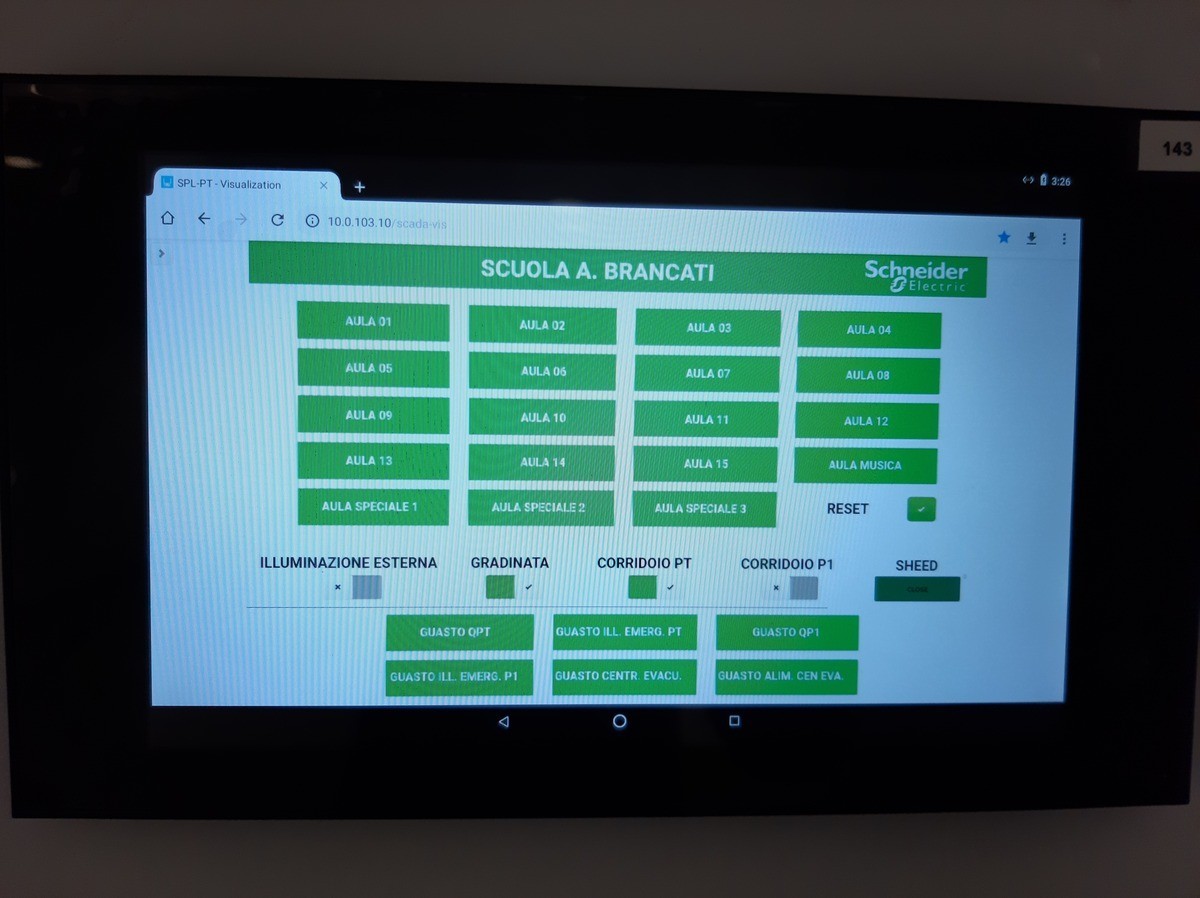

- Remote and customized temperature

- both natural and artificial light control

- high acoustic performance obtained to create the best environment for learning and teaching

- parking for bicycles, electric charging stations for cars

- indoor air quality by mechanical filtered ventilation climate system with a CO2 monitoring able to guarantee higher levels of indoor air quality with the air exchange of 5 volumes per hour

- natural ventilation thanks to opening in the upper window sections

Indoor air quality:

Mechanical filtered ventilation climate system with a CO2 monitoring able to guarantee higher levels of indoor air quality with the air exchange of 5 volumes per hour

Natural ventilation:

Thanks to openings in the upper window sections

Solar control:

Integrated and motorized shutters with sensors for light and overheating control

Green roof:

Made of Mediterranean plants with low water need to moderate the impact of high temperatures, capture storm water, abate pollution, and act as carbon sinks, while enhancing biodiversity

Reused rainwater:

Rainwater collecting tanks for green spaces, and the green roof

Water consumption reduction:

Water consumption has been reduced thanks to taps with aerators that reduce water flow by 50%, and flash-water tanks.

Envelope efficiency:

The ventilated wall made of modular porcelain stoneware avoids overheating, minimize losses, and also reduces the maintenance costs of the facade

Energy Consumption Reduction:

-59,07% considering TEP reduction compared to standard construction (UNI TS 11300 and UNI EN 15193) and - 34,8% reduction of annual costs thanks to:

- Envelope efficiency: the thermal insulation, the thoroughly study of thermal bridges, the green roof and ventilated wall made of modular porcelain stoneware avoids overheating, minimize losses and reduces also the maintenance costs of the façade

- the high efficiency heat recovery unit

- optimized lighting (LED)

- automatic consumption monitoring control system to make also friendly and easy the use of building

Renewable energy:

Optimal production of electric energy due to the PV panels

- Photovoltaic installation of 158,40 m2;

- n. 96 photovoltaic modules of 300Wph and 1,96 m2 each

- Photovoltaic power ratings 28,8 Kw continuous current

- Inverter Solaredge 27,6KW alternate current

- Not expensive PV system due to the envelope high performance

- 113,5 kW heat pump

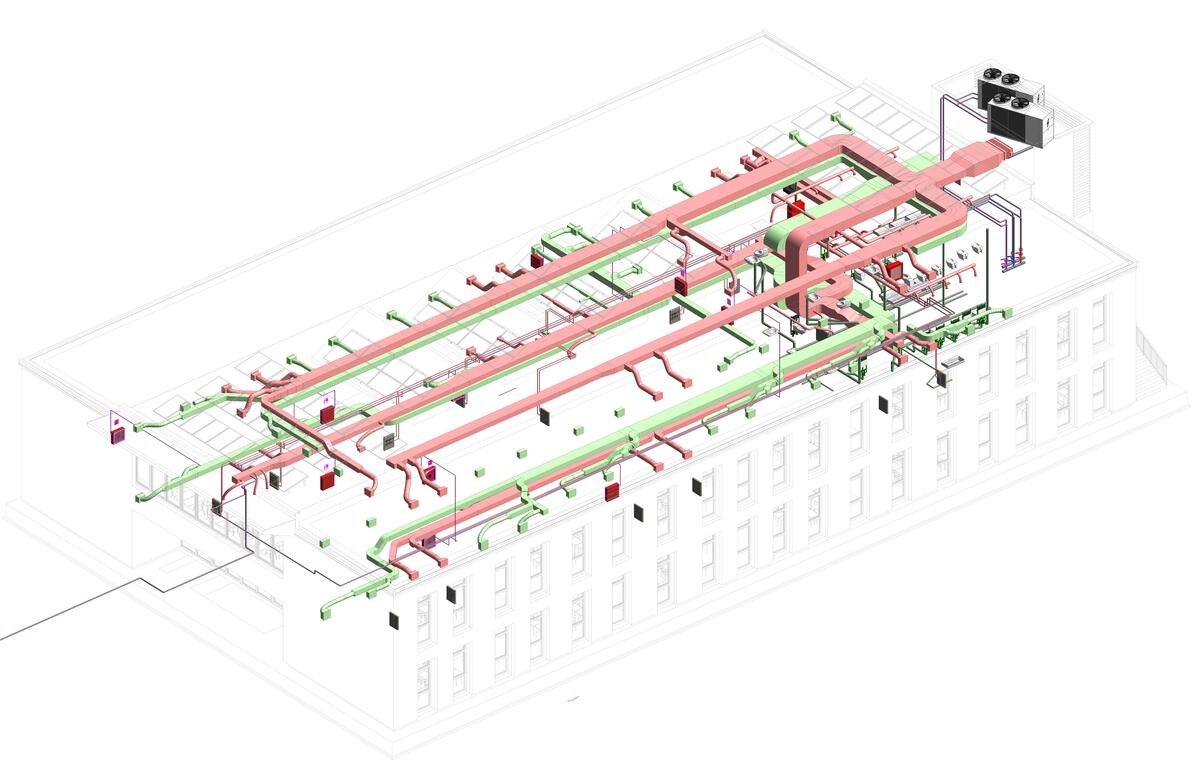

- heating system: floor heating and VAV system (variable air volume)

- cooling system: floor cooling and VAV system (variable air volume)

See more details about this project

https://www.macrodesignstudio.it/?portfolio=nuova-scuola-secondaria-antonio-brancati-a-pesarohttps://gbcitalia.org/web/guest/-/a-pesaro-la-prima-scuola-leed-platinum-d-europa

https://www.ingenio-web.it/29662-risposta-ai-cambiamenti-climatici-della-citta-di-pesaro-la-scuola-brancati-edificio-piu-sostenibile-deuropa

https://www.ingenio-web.it/29463-primato-europeo-per-la-nuova-scuola-antonio-brancati-di-pesaro-certificata-leed-v4-platino

https://www.ilsole24ore.com/art/a-pesaro-scuola-certificata-leed-platinum-ADA3lKNB

Photo credit

Margherita Finamore photo credit

Formula Servizi & Idrotermica Coop (Sunset comunicazioni) video credit

Contractor

Construction Manager

Stakeholders

Construction company

Idrotermicacoop

Michele Gardella gardella[a]idrotermicacoop.it

https://idrotermicacoop.it/technical assistant for mechanical plants

Construction company

Formulaservizi

Mirco Valdifiori mircovaldifiori[a]formulaservizi.it

https://www.formulaservizi.ittechnical assistant of the construction

Construction company

SIEM IMPIANTI

Michele Meazzini meazzini[a]siemimpianti.it

https://www.siemimpianti.it/technical assistant for eletric plants

Certification company

MDS MacroDesignStudio

Giorgia Lorenzi giorgia.lorenzi[a]macrodesignstudio.it

https://www.macrodesignstudio.it/LEED-AP

Contractor representative

Pesaro Municipality

Margherita Finamore m.finamore[a]comune.pesaro.pu.it

http://www.comune.pesaro.pu.it/Project Manager

Construction company

CONSCOOP - CONSORZIO FRA COOPERATIVE DI PRODUZIONE E LAVORO - Formula Servizi - Forlì - Idrotermica Coop - Forlì - SIEM Impianti – Cesena (FC)

Mirco Valdifiori mircovaldifiori[a]formulaservizi.it - Forlì

Contracting method

Other methods

If you had to do it again?

I would study better the impacts of the materials to prove the circularity of the building, as if it was a bank of materials. I would improve the eco-design and the use of bio-based materials to assure that the building would be dismantled as much as possible, to maximize the quantity of re-usable materials. I would also improve the use of light structure assembly technology to have a clean and environmental friendly construction site.

Building users opinion

Users are generally very satisfied. Four categories are considered: the point of view of the teachers, the students, the school assistants, and the parents.

A campaign to collect data is already planned. It should consists of individual reports and interviews, but due to the present COVID-19 situation, it hasn't started yet.

All users appreciate the brightness of the natural and artificial light as desired, the acoustic comfort due to the absence of background noise in the classrooms or any noise disturbance from outdoor, the thermal comfort which is tailor-made in every classroom thanks to the sensors, and the view of the park surrounding the school.

The students appreciate very much the glass walls of the classes that allow them to see the other classes, thus generating a sense of community.

What users especially liked the most, particularly the parents, is the indoor air quality (especially considering the present COVID-19 situation) thanks to the mechanical filtered ventilation climate system, with a CO2 monitor, able to guarantee higher levels of indoor air quality, reducing the risk of contagion.

The general opinion is that this school creates an environment friendly spaces where students can be educated on sustainability, aware of being part of a community, and can understand how important the relationship between the human being and the environment is.

Energy consumption

- 26,80 kWhpe/m2.year

- 55,10 kWhpe/m2.year

Envelope performance

- 0,22 W.m-2.K-1

- 0,38

- 2,26

More information

The school has been operational since the beginning of the school year, 17th Sept. 2020. The real consumptions and performances have been monitored by the Department of Industrial Engineering DIN (University of Bologna) for 4 years to check all the comfort data. At the moment the monitoring is in progress. A blower door test has been realized to assure the effectiveness of the envelope.

Real final energy consumption

60,76 kWhfe/m2.year

Systems

- Condensing gas boiler

- Heat pump

- Low temperature floor heating

- VAV System

- Heat pump

- Reversible heat pump

- VAV Syst. (Variable Air Volume system)

- Floor cooling

- Double flow heat exchanger

- Solar photovoltaic

- Heat pump

- 57,00 %

Smart Building

Urban environment

- 3 649,00 m2

- 23,50 %

- 10 321,00

Product

Heat pump NRL 0280/0750

AIRMEC

https://global.aermec.com/it/

Air/water reversible heat pump

This product helps to achieve the LEED scoring on the minimum and enhanced energy performance

ECP AHU - RHOSS AHU 6.02

RHOSS S.p.A. ITALY

https://www.rhoss.com/it/

Air Handling Unit ADV

This product helps to achieve the LEED scoring on the minimum and enhanced energy performance and on air quality Minimum and IAQ Performance

P3 DUCTAL CARE PLUS

P3 Italy

https://www.p3italy.it/

air channels

Keratwin K20 - ventilated wall system AGROB-20

AGROB BUCHTAL

https://agrob-buchtal.de/en/architect-plannerFinishing work / paints, mural, wallcoverings

extruded ceramic titles for wall coverings in outdoor areas used for the ventilated wall facade

CELENIT AB

CELENIT S.p.A.

https://www.celenit.comFinishing work / Partitions, insulation

Thermal and acoustic insulation in buildings - Suspended ceilings used in buildings

MR credit Product Disclosure and Optimization – Environmental Product Declarations

DOP VAEPLAN F / V FR / V

Derbigum

https://www.derbigum.itFinishing work / Partitions, insulation

roof waterproof

SS credit Heat Island ReductionMR credit Product Disclosure and Optimization – Environmental Product Declarations

smartroof_thermal

Knauf

https://www.knaufinsulation.itFinishing work / Partitions, insulation

Rock mineral wool SmartRoof Base and SmartRoofThermal are used as a thermal, acoustical and fireinsulation product.

MR credit Product Disclosure and Optimization – Environmental Product DeclarationsMR credit Product Disclosure and Optimization – Sourcing of Raw Materials

FSD 20 / PLUS-E/PRO 80 / PRO 170 TIPO/ ROOF SOIL/SEDUM/STABILFILTER SFE

DAKU

https://www.daku.itFinishing work / Partitions, insulation

green roof

SS credit Heat Island Reduction

COVER 80

MAYER & CO BESCHLAGE

https://www.maco.eu/it-IT/MaicoFinishing work / Exterior joinery - Doors and Windows

wooden windows

MR credit Product Disclosure and Optimization – Environmental Product DeclarationsMR credit Product Disclosure and Optimization – Sourcing of Raw Materials

Isover X60 VN + Isover Clima 34

Saint Gobein

https://www.saint-gobain.itFinishing work / Partitions, insulation

wall insulation

MR credit Product Disclosure and Optimization – Environmental Product DeclarationsMR credit Product Disclosure and Optimization – Sourcing of Raw Materials

Construction and exploitation costs

- 3 707 579,00 €

- 4 647 540,00 €

- 36 965,00 €

- 137 000 €

- 2 886 890 €

- 816 000 €

Energy bill

- 12 575,00 €

Life Cycle Analysis

Water management

- 1 897,00 m3

- 24,00 m3

Indoor Air quality

Comfort

GHG emissions

- 9,66 KgCO2/m2/year

- 520,40 KgCO2 /m2

- 60,00 year(s)

- 579,70 KgCO2 /m2

Reasons for participating in the competition(s)

Energy & Temperate Climates requirements: As the school is built in a region with a Mediterranean climate, the building envelope also needs to prevent heat losses and simultaneously defend against overheating due to rising temperatures in spring and in autumn as the consequences of climate change. A thorough study of heat gains and losses was carried out to optimise the thermal capacity of the building envelope, which has been achieved by using a green roof, automated solar shadings, and the ventilated wall. By the Green Public Procurement activity, the call for tender made mandatory the N-ZEB standard and the LEED certification scheme. The combination of these two mandatory requirements guaranteed to obtain the nZEB school with the LEED Platinum certification with the score of 88 points.

Energy Consumption Reduction: -59,07% considering TEP reduction compared to standard construction (UNI TS 11300 and UNI EN 15193) and - 34,8% reduction of annual costs thanks to:

- Envelope efficiency: the thermal insulation, the thoroughly study of thermal bridges, the green roof and ventilated wall made of modular porcelain stoneware avoids overheating, minimize losses and reduces also the maintenance costs of the façade

- the highly efficient heat recovery unit

- optimized lighting (LED)

- automatic consumption monitoring control system to make also friendly and easy the use of the building

Renewable energy: the building will be equipped with a photovoltaic generation system located on the roof and with a specific power of 28.8 kwp thanks to the installation of 96 monocrystalline silicon panels with a power of 300 Wp each. The PV system will be installed on the central part of the roof of the school building, with inclination equal to 8, with anchorage to the structure according to the indications in the structural tables and with monocrystalline silicon panels 300wp. The renewable energy production is sufficient to cover the building energy need and made it a nZEB.

Optimal production of electric energy due to the PV panels;

- Photovoltaic installation of 158,40 m2;

- n. 96 photovoltaic modules of 300Wph and 1,96 m2 each

- Photovoltaic power ratings 28,8 Kw continuous current

- Not expensive PV system due to the envelope high performance

- Inverter Solaredge 27,6KW alternate current

- 113,5 kW heat pump

- heating system: floor heating and VAV system (variable air volume)

- cooling system: floor cooling and VAV system (variable air volume)

The ventilated wall, made of porcelain stoneware, reduces the maintenance costs of the facade and, with the green roof and solar shading supports minimization of energy demand. As a result, mechanical plants are simpler and less expensive in terms of work costs and maintenance. All these technical and functional features increase building adaptability, durability, and resilience in accordance with the circular economy principles.

In addition to LEED Platinum certification with a score of 88 points, it was achieved the near Zero Energy Building standard thanks to the energy efficiency envelope, the highly efficient HVAC and light system and the green roof combine with the rooftop photovoltaic system to reduce the school’s carbon footprint. The friendly monitor system installed helps the users to reach the minimum consumption.

In addition the majority of the materials used are provided with EPD certifications. It was also organized the material management system in the construction site by selective in-situ storage of deconstruction waste and selective collection of all packing and processing waste. During all the process 556,630 kg of waste were created and thanks to all material flows monitored 546,378 kg was recycled and recovered achieving a 98% recovered waste.

The shape and position of the building was studied and orientated to best exploit solar radiation and optimize the free solar gains and natural lighting and shading.

The school building is provided by:

- integrated and motorized shutters with sensors for natural light and overheating control

- green roof made of Mediterranean plants with low water need to moderate the impact of high temperatures, capture stormwater, abate pollution, and act as carbon sinks while enhancing biodiversity

- rainwater collecting tank for green spaces and the green roof to reuse rainwater

- taps with aerators that reduce water flow by 50% and flash-water tanks for reducing water consumption.

The low impact is also due to the zero-land consumption, the LCA that takes into account 5 specific benchmarks, the waste management during the construction phase.

Due to the highly efficient HVAC and light system combine with the usage of the natural light high comfort is reached to create the best environment for learning. Also, the requirements for acoustic performance and the selection of the appropriate performing systems were deeply analysed to meet the specifications for high-performance results by providing solutions that comply with standards and deliver the best sound experience based on science. The acoustic standard reached has been monitored in situ to check the results and helps to create the best environment to learn too.

Much was done to optimize the design in air quality, so today it is also possible to guarantee comfort, safety, and security in excellent conditions. This building is provided with a mechanical filtered ventilation climate system with a CO2 monitor able to guarantee higher levels of indoor air quality. Please note that in Italy natural ventilation system in buildings is sufficient by law. Natural ventilation significantly depends on the temperature difference between the indoor and the ambient air and the current wind situation. As a result, sufficient natural ventilation cannot be guaranteed at all times. In the long-term, it is also important to structurally improve the HAVC system since poor indoor air quality leads to, among others, headache, fatigue, and reduced learning performance. This mechanical ventilation system installed in the school ensures a continuous air exchange throughout the year creating the best health conditions within the school to also reduce the risk of contagion.

Building candidate in the category

Energy & Temperate Climates

Low Carbon

Health & Comfort

Margherita Finamore

Responsabile del Progetto (tecnico e amministrativo)/ Progettista e Direzione Lavori