Waste collection logistics base

Last modified by the author on 11/05/2020 - 14:43

New Construction

- Building Type : Other building

- Construction Year : 2019

- Delivery year : 2019

- Address 1 - street : Les Taffeneaux, Le Château-d'Olonne 85180 LES SABLES D'OLONNE, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 1 000 m2

- Construction/refurbishment cost : 1 700 000 €

- Number of none : 7 none

- Cost/m2 : 1700 €/m2

-

Primary energy need

77.2 kWhep/m2.an

(Calculation method : RT 2012 )

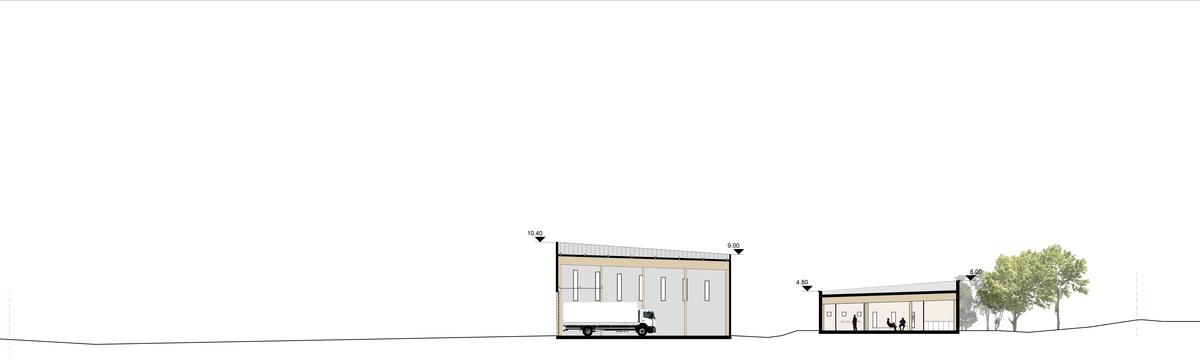

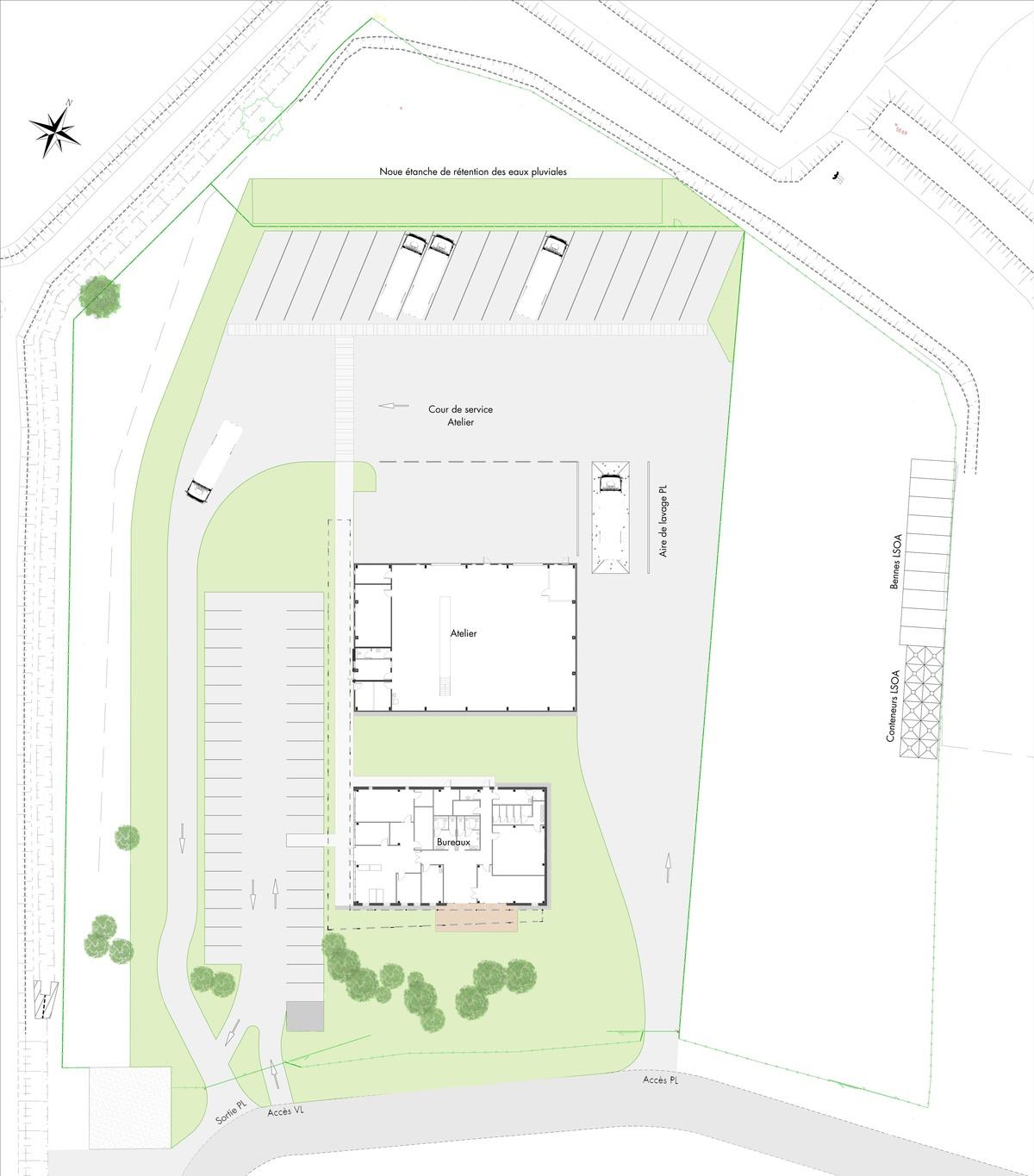

The project was commissioned by the agglomeration of Sables d'Olonne for the organization of waste collection. One building houses the offices and social premises and the other the truck maintenance workshop, both are linked by a wooden frame awning. The shape of the buildings is inspired by their bioclimatic orientation , the office area opens towards the South and the West while the workshop side is turned towards the North to take advantage of an indirect light by avoiding overheating. The set is designed with a wood structure and biobased insulation .

The construction is efficient and low carbon cost equivalent to "standard" constructions . A locally available resource has been used: Hemp, of which Vendée is the second largest producing basin in France, and which is inseparable from the wood frame. The vertical walls are insulated with wood fiber and hemp concrete or vegetable wool and vegetable wool roofs. The orientation of the premises was designed to allow solar gain without causing overheating. The roof was chosen in white tint to minimize the effect of solar radiation.

An innovation reduces the project to 8 months only: prefabricated panels in wood frame, wood fiber and hemp concrete. The panels were assembled in the workshop during the structural work, allowing the hemp concrete to dry before being placed on the laminated wood structure. The insulation of the plant wool workshop also represents an advance in the construction of industrial buildings made of metal cladding, usually insulated with mineral wool. A double flow ventilation coupled with a powerful envelope allows to minimize the contributions in heating.

Sustainable development approach of the project owner

The project manager did not aim to build a biobased building but was seduced by the approach proposed by CAN. The agency was able to convince the contracting authority for the use of biosourced materials. The cost of wood construction and the insurability of hemp were the two main points on which it was necessary to reassure the contracting authority. Awareness-raising work with companies was also put in place because they did not have knowledge of hemp use. The particularities of the construction incorporating hemp were explained to the carpentry company Carpenters of the Atlantic. All this happened very simply and all the actors played the game which allowed to realize the project without hindrance or additional delays. The project owner is very satisfied with the missions and services provided.

Architectural description

The two buildings, offices and workshop, have been separated to avoid any acoustic discomfort and are connected by a wooden frame canopy which turns in solar protection on the southern part of the offices. This awning, conceived as a link between the two entities, is punctuated by the design of staggered columns and the arrangement of V-shaped wooden beams. The shape of the buildings was inspired by their bioclimatic orientation, the office part opens towards the South and West to capture while the workshop side is turned to the North to take advantage of an indirect and diffuse light while avoiding overheating. The inverted slopes of the roofs allow the two buildings to respond and reduce visually the height difference between these templates necessarily different because of the exploitation. Both volumes are underlined by the contrasting shades of their facades. A particular reflection was conducted to design this set with a wood structure and biosourced insulation without constraining the architectural writing.

Biobased materials in the broad sense are for our agency indissociable wood in low carbon construction. The source of the materials is also important in order to reduce the carbon impact of the construction. A locally available resource was particularly used: Hemp, of which the Vendée is the second largest producing basin in France.

Both buildings have a wooden structure and are insulated with biobased materials. The walls of the office part were designed in prefabricated walls in wood frame, wood fiber and hemp concrete filling. Those in the workshop are insulated with hemp, linen and cotton wool, as well as the roofs of both buildings.

The orientation of the premises was designed to allow solar gain without causing overheating. The living rooms and offices are oriented South and West and protected by solar breezes adapted to the orientation while the technical and wet premises are buffer areas in the north. The roof was chosen in white tint to minimize the effect of solar radiation.

A constructive innovation allowed the project to be completed in just 8 months and to respect the constrained deadlines of the specifications. This innovation lies in the development of prefabricated panels in wood frame, wood fiber and hemp concrete. The panels were thus pre-assembled in the workshop during the structural work, allowing the hemp concrete to dry.

The insulation of the plant wool workshop also represents an advance in the construction of industrial buildings made of metal cladding, usually insulated with mineral wool. All the walls of two entities are supported by glued laminated timber frames. A double flow ventilation coupled with a powerful envelope allowed to minimize the contributions in heating.

Building users opinion

Very good return of users of the site, the building is functional, practical, clean, working conditions are optimal.

The project owner is very happy with the building: "This project makes the elected officials want to produce other constructions with biosourced materials"

If you had to do it again?

The main difficulties with biosourced materials are psychological, because most people associate bio-sourced materials with uninsurable and high-cost self-construction projects. It is therefore necessary to convince by demonstrating insurability and financial feasibility. For some uses, the regulation vis-à-vis biosourced materials still has some gaps. The dialogue with the contracting authority and the control offices helped to remove concerns.

See more details about this project

http://can-ia.fr/base-logistique-bom/https://www.construction21.org/france/articles/fr/green-solutions-base-logistique-pour-l-organisation-et-la-collecte-des-dechets-des-sables-d-olonne.html

Photo credit

CAN-ia

Contractor

Construction Manager

Stakeholders

3C ECO STRUCTURES

http://www.3c-eco-structures.com/BE structure

Thermal consultancy agency

AIREO ENERGIES

BE fluids

Company

SOFULTRAP

Earthmoving / HHT

Company

VOISIN CONSTRUCTIONS

Big work

Company

Les Charpentiers de l'Atlantique

Wood frame

Company

Cruard Couverture

Roofing / Siding

Company

ISOLAVIE

Exterior lime plaster

Company

CSM 79

Locksmith

Company

Serrurerie Luconnaise

Exterior joinery / curtain wall

Company

SARL Lilian

Partitions / dubbing / false ceilings

Company

SARL Terrien

Interior joinery

Company

SARL CCV

Floor coverings and hard walls

Company

SARL Aucher

Painting

Company

CAJEV

Green areas / fences

Company

SNCV Ouest

Heating / ventilation / plumbing

Company

SNGE Ouest

electricity

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 77,20 kWhep/m2.an

Envelope performance

- 0,76

Systems

- Heat pump

- Individual electric boiler

- No cooling system

- Double flow heat exchanger

- No renewable energy systems

Smart Building

Urban environment

- 15 482,00 m2

- 15,48 %

- 2 784,00

Product

Chenevotte Chanvribat® (Hemp concrete)

TRADICAL®

http://www.bcb-tradical.com/Finishing work / Partitions, insulation

Among the bio-based materials, hemp needs to be better known. This plant growing without plant protection product and without irrigation is very useful for crop rotation. It is then fully recoverable: its highly nutritious seeds are processed for food and cosmetics Its fiber is used for textiles, paper or bio-plastic The chènevotte, located in the heart of the stem, serves as mulch for horticulture and granulate for

Hemp concrete is a mixture of hemp, a mineral binder and a mixing water. This nonstructural material is a very good hygro-thermal regulator, which brings both insulation and inertia to the building, it works

as a monomasse. Cost of hemp concrete per m² / ep 200mm (excluding wood frame): 108,00 € / m² Its perspirancy quality or high permeability to water vapor makes it an excellent hygienic regulator. It is also a so-called "phase change" material giving off latent heats of change of state. In other words, this feature ensures optimal summer and winter comfort, without the need for electrical systems. The wall alone manages the phase shifts of temperature and humidity that the structure can experience throughout a year. These qualities make it a high-performance material which, far above the thresholds, meets the thermal regulations in force. In addition to its hygrothermal qualities, hemp concrete is a carbon sink for the structure, storing more CO2 than its life cycle emits. It also does not emit volatile organic compounds and thus ensures healthy atmosphere for the user by regulating the surface moisture on the surface of the interior walls. Hemp concrete avoids the risk of condensation that can be observed in conventional housing when mechanical ventilation malfunctions for example.

The product is under technical notice and holds its professional rules. The workers made the prefabrication of wood-concrete hemp panels in the workshop. They were able to appreciate the comfort of the workshop work and the speed of implementation on site. Hemp concrete provides significant thermal and hygroscopic comfort for its occupants.

Tradical® Thermo Lime (Hemp Concrete)

TRADICAL®

http://www.bcb-tradical.com/Finishing work / Partitions, insulation

Material designed from Gypsum, significantly less energy intensive than cement for its production. Technical information is available here: http://www.bcb-tradical.com/wpcontent/uploads/2018/02/Brochure-Beton-Chanvre-Tradical-12-2017.pdf Cost of hemp concrete per m² / ep 200mm (excluding wood frame): 108,00 € / m²

The material meets the NF DTU 26.1 requirements. The workers appreciated the prefabrication of wood-concrete hemp panels in the workshop. Because of the comfort and the speed of setting up on site. The concrete brings a thermal and hygroscopic comfort very appreciated by the occupants.

Rigid Steico integral wood wool panels (incorporated on prefabricated wood / hemp concrete panels)

Steico

https://www.steico.com/fr/Finishing work / Partitions, insulation

Wood wool is a biobased material derived from sawmill waste. This insulation has been exploited as ITE and support coatings (walls). Soprema® offers similar panels that benefit from technical advice, for applications on masonry and timber framing.

This material applied as ITE provides additional insulation and eliminates almost all thermal bridges of the building. Its implementation in shop or on site remains simple and fast.

Biofib Trio®

CAVAC

02 51 36 51 51

https://www.coop-cavac.fr/Finishing work / Partitions, insulation

This material is composed of 92% of vegetable fibers (flax, hemp and cotton) and 8% of binder. Link: https://www.biofib.com/files/en/BIOFIB-Trio.pdf

This material and under technical notice: https://www.biofib.com/files/BIOFIB_TRIOAvis_technique_CSTB_Murs.pdfIt does not trigger irritation to the skin. If inhaled, the body is able to

easily destroy this type of plant fiber. In fact, it is appreciated by the workers who implement it. He brings

also a remarkable thermal and acoustic comfort within the building, thus guaranteeing a working space

pleasant. Companions no longer wish to lay mineral wool.

Construction and exploitation costs

- 110 500 €

- 1 797 690 €

Water management

Indoor Air quality

Comfort

GHG emissions

- 3,00 KgCO2/m2/an

Life Cycle Analysis

Reasons for participating in the competition(s)

La base logistique pour l'organisation et la collecte des déchets est constituée de deux espaces de travail : un atelier et des bureaux. L'utilisation de matériaux sains et biosourcés, comme le bois et le chanvre, bénéficie à la santé des usagers. La structure bois apparente dans l'atelier rend l'espace chaleureux. Le confort au travail est amélioré avec des espaces de détente tant à l'intérieur qu'à l'extérieur.

Building candidate in the category

Health & Comfort