Timber/Straw Passive residence Jules Ferry

Last modified by the author on 19/02/2014 - 14:59

New Construction

- Building Type : Collective housing < 50m

- Construction Year : 2013

- Delivery year : 2013

- Address 1 - street : rue du 10ème BCP 88100 SAINT-DIE-DES-VOSGES, France

- Climate zone :

- Net Floor Area : 2 707 m2

- Construction/refurbishment cost : 4 265 000 €

- Number of Dwelling : 26 Dwelling

- Cost/m2 : 1575.54 €/m2

Certifications :

-

Primary energy need

37 kWhep/m2.an

(Calculation method : RT 2012 )

homes Jules Ferry: 2 buildings housing 26 apartments counting T3 (75m ²) and T4 (90m ²) .

Sustainable development approach of the project owner

The will of the entire team project owner and mastery of work was to realize a transaction with the lowest impact on the environment with:- Use of bio-materials sources mainly (wood, straw, ...)- Have a building that manages the most independent manner possible and low maintenance- Use of free and renewable energy (solar, geothermal, heat recovery on ventilation and greywater lift REGENERATIVE ...)The costs of energy and loads of achievement are as low as possible for tenants:- Passive construction- Equipped kitchen oven and hob Induction Class A +- Equipped showers taps a button ...Architectural description

The project consists of 2 buildings which volumetrie provides architectural and urban integration by progressive hierarchization of the Crees and recovery volumes neighboring volumetrics.The use of vernacular materials (red clay and wood) contemporary manner can present strong facades.If you had to do it again?

Without hesitation.The total of 26 housing instrumentation and energy system provide real-time consumption and parameters of the entire project.We have found that we reach widely expected level of performance.

See more details about this project

http://www.toit-vosgien.com/fr/performances-energetiques/immeuble-bois-grande-hauteur.htmlStakeholders

Contractor

SA LE TOIT VOSGIEN

St Dié 88100

http://www.toit-vosgien.comConstruction Manager

ASP Architecture

St Dié 88100

http://www.asparchitecture.frThermal consultancy agency

Terranergie

Saulcy 88100

http://www.terranergie.fr

Ingénierie Bois

Bischheim

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 37,00 kWhep/m2.an

- 75,00 kWhep/m2.an

Real final energy consumption

40,00 kWhef/m2.an

Envelope performance

- 0,50

- 0,30 Rapport test AvNR

More information

The actual consumption is much lower than the RT2012 calculation, the higher the coefficient of EP / EF passage 2.58 is not relevant here because the vector electric energy supply is 100% renewable energy is a primary factor tending to 1

Systems

- Geothermal heat pump

- Others

- Solar thermal

- Heat pump

- Solar Thermal

- Other hot water system

- Others

- Double flow heat exchanger

- Solar Thermal

- Heat Pump on geothermal probes

- 100,00 %

Smart Building

Urban environment

- 2 560,00 m2

- 765,00 %

- 845,00

Product

Structure Wood and Straw Insulation

Structural work / Structure - Masonry - Facade

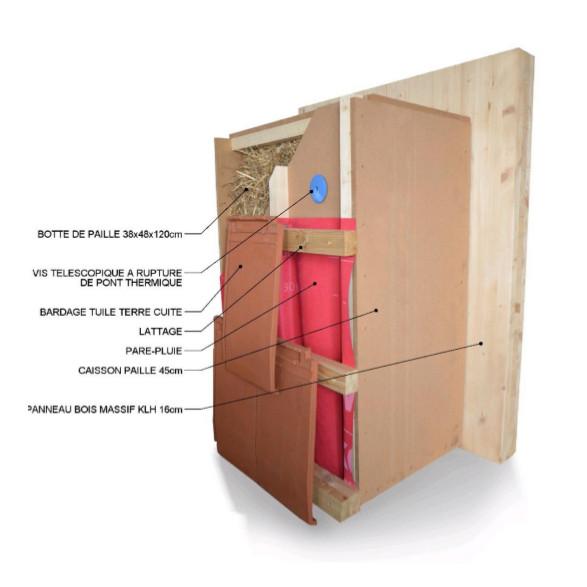

The constructive principle is based on panels of solid wood laminated spruce. They constitute the envelope and floors of the project and remain largely apparent in the interior of the apartments. The external insulation is composed of prefabricated boxes filled with straw. Particular attention was paid to the elimination of thermal bridges: fixings out of the straw bridge, triple glazing joinery isolated.

Constructive advantage of wood and straw:- The wood is light, the vibrating masses sought are weak and seismic forces are less important than a massive concrete structure. Tests show a behavior when earthquake very favorable: dissipation of energy in many assemblies.- The structure of wood for a fire, has its charred outer layer protects the heart and then the structure that retains its mechanical strength. (Conversely, the metal heats quickly loses its bearing capacity). The straw, in the absence of oxygen (in boxes) and slowly carbonized also protects the bearing structure for more than one hour. Its insulation properties and phase shift are a temperature of 900 ° C on one side of the boot takes 20 minutes increase by 1 ° C on the other side. This is a very large protection against fire.- A quick and healthy worksite clean. Prefabrication and method of construction filiere dryer allows to realize a cleaner, faster site (no drying time). The use of bio-materials sources significantly reduces health risks for workers and residents.

Box of simple and economic straw

Finishing work / Partitions, insulation

Filling prefabricated insulated boxes with the help of simple boots agricultural straw, economic and particularly renewable material. Please note: the entirety of used straw (10 hectares) shall be renewed within one year.Shop fabrication and delivery to site.Mounting boxes directly on the solid wood and use as carriers of the larch cladding battens and terracotta structure.

Carbon balance of positive construction of 1 100 tonnes of Co2!- 1000 T C02 stored in 1,000 m3 of wood used- 200 tonnes of CO2 stored in the 600 m3 of straw used- 100 tonnes of CO2 consumed during constructionFor comparison, the construction of the same building classical solution (concrete / polystyrene / PVC) would have resulted in a negative carbon balance 600 tonne of C02, or the equivalent of 50 years of heating and hot water to this building if using gas or 6,000,000 km traveled by a recent car!Mastering the use of C02 during construction not to burn a few months several decades of energy needs is an excellent preamble to the construction of a simple and efficient building.

KLH - Lignatec

contact[a]lignatec.fr

http://www.lignatec.frStructural work / Structure - Masonry - Facade

Panneau bois contrecollé KLH

KLH - Lignatec

http://www.lignatec.frStructural work / Structure - Masonry - Facade

Panneau structurel en bois contrecollé KLH. Le panneau est employé ici en façade, refend et plancher intermédiaire. Il reste apparent sur certains murs et en sous face de plancher. Le panneau KLH est support de l’isolant paille qui est directement vissé par l’extérieur. L’épaisseur des murs diminue en fonction de l’étage. Le panneau apporte sa légèreté et sa rigidité pour répondre aux efforts de vent et sismiques. Temps de pose de l’ensemble de la superstructure : 3 semaines.

légèreté, rigidité, utilisation en zone sismique, précision usinage, étanchéité à l’air, possibilité de le laisser apparent