Resilience - The farm of possibilities

Last modified by the author on 27/05/2021 - 14:31

New Construction

- Building Type : Other building

- Construction Year : 2019

- Delivery year : 2020

- Address 1 - street : 29 Rue d'Amiens 93240 STAINS, France

- Climate zone : [Cfb] Marine Mild Winter, warm summer, no dry season.

- Net Floor Area : 1 883 m2

- Construction/refurbishment cost : 3 072 000 €

- Number of none : 1 none

- Cost/m2 : 1631.44 €/m2

-

Primary energy need

100 kWhep/m2.an

(Calculation method : RT 2012 )

Résilience is the head office of Novaedia, a work integration cooperative that develops a local, organic and solidarity food loop. It was built on La Ferme des Possibles in Stains (93).

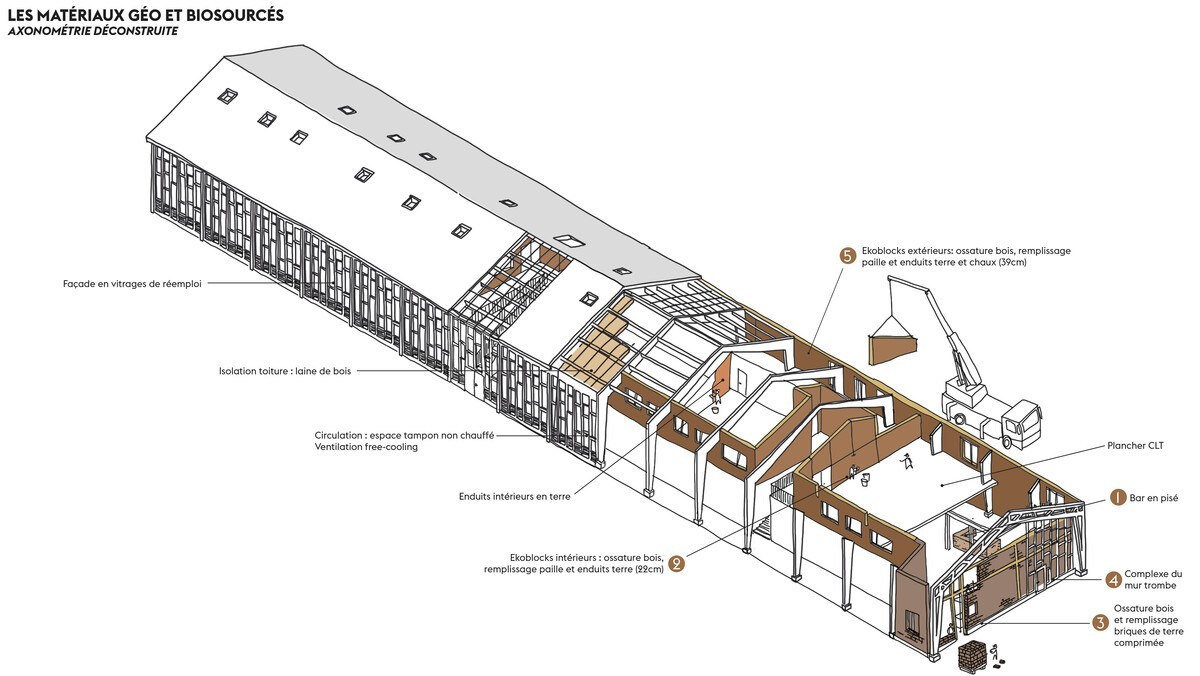

In line with the cooperative's practices, inspired by permaculture and in symbiosis with its surrounding area, the building was conceived in a bioclimatic way with bio / geo-sourced materials and reused materials. It reconciles a low-tech and high-tech approach within a single building: waterspout walls and raw earth plasters rub are combined to a kitchen-laboratory and a heat-fridge-pump.

The building has a wooden structure, glued laminated porticoes and CLT floors, made with wood from French forests. The insulating facades, interior and exterior, are made up of prefabricated wooden boxes filled with compressed straw and plastered with raw earth on both sides.

The glazed facades are made with single-glazed wooden windows, retrieved from the thermal renovation of a social housing complex in Epinay-sur-Seine, less than 4 km from the site.

The soil from the spoil was used to make the finishing plasters, by mixing it with cellulose fiber from the packaging boxes on the site. This earth is also present in the cafeteria bar, mixed with crushed concrete to make adobe walls. These mixtures avoided adding sand to stabilize this very clayey soil.

Many reuse materials have been used in the construction and equipment of Resilience. Their origins are multiple: Bellastock, Urban Metabolism, Réavie, Bon Coin, the City of Paris or gleaned by the companies themselves on their renovation sites.

The solar gains are favoured by buffer spaces and a waterspout wall. Given the large presence of refrigerated premises, the heated spaces benefit from a thermofrigopump, thus recovering the energy used to produce cold to heat the premises.

Sustainable development approach of the project owner

The approach of the Novaedia cooperative is based on permaculture. It is not only a question of how to cultivate, but above all of associating the existing human resources and energies in the area, making them work together to bring about new practices, adapted to the world to come. Hence the name Resilience.

Novaedia's environmental approach is consistent with these principles and its commitment to integrating people excluded from the working world. The raison d'être of Novaedia is indeed to foster a social and solidarity economy in working-class neighborhoods to develop eco-activities, by allowing the support and training of disabled workers and young inhabitants towards promising professions.

Its know-how is to reconcile local development, sustainable development and professional integration, according to the idea that the resources of some meet the needs of others and that waste does not exist. La Ferme des Possibles aims to become an educational showcase to build awareness of permaculture and sustainable development.

Thanks to the construction of Resilience and the developments of La Ferme des Possibles, Novaedia aims to make it an experimental urban farm, which aims to be replicated in all urban areas. The objective is to demonstrate that a plot of approximately one hectare is sufficient to accommodate orchards and vegetable gardens, greenhouses, central kitchen, logistics and restaurant. But also by associating it with neighboring farms, local players in the social and solidarity economy, local communities and residents, a dynamic of citizen mobilization can be initiated around the issues of food, environment and biodiversity in working-class neighborhoods while creating jobs for the future.

Architectural description

Résilience houses logistics and production premises on the ground floor: storage, packaging, kitchen laboratory and a cafeteria. The first floor accommodates offices, training and meeting spaces.

The architectural aspect is a volume of great simplicity, inspired by a farmhouse, in reference to its agricultural vocation, totally transparent on its most exposed facades, making its materiality obvious: reuse, wood, earth and straw .

Distribution constraints within this complex culinary preparation laboratory program overlap perfectly with bioclimatic principles. Only a narrow strip of land was constructible, oriented north-south. This linearity is fairly consistent with the program, which results in a sequencing of functions. From the receipt of food to the delivery of meals, a series of operations induces this sequencing, following a forward march; from the reception of foodstuffs to the distribution of finished products, without crossing. The plan was therefore designed with a double peripheral circulation, making it possible to irrigate the premises in a simple and functional way, without crossing clean and dirty circuits. These unheated distribution spaces, on the outskirts of the building, form buffer spaces, lit by glazed facades in re-used joinery. The interior facades housing the heated premises are made of wooden boxes filled with compressed straw, covered with a mud plaster on both sides. The southern end of the chain houses the restaurant.

The south gable is treated as a waterspout wall, made of reused BTC bricks (from the Ville des Terres of BELLASTOCK). Surrounded by the gardens of the neighboring pavilions, it heats, cools and illuminates the restaurant while preserving the privacy of the place.

Building users opinion

Resilience occupants are proud of their building. However, they sometimes regret the temperature in the buffer spaces in winter when there is no sun! We have perhaps not communicated enough on the conditions of use of such a space, which is to be considered as an outdoor space, sheltered from rain and wind, which can participate in the heating of the building, but only on sunny days ...

If you had to do it again?

If it had to be done again today, it would be zero concrete! Since we have found a way to not use concrete foundations, thanks to screw piles supporting a wooden floor. Then, the glazed facades of the buffer spaces would be double glazed and not single glazed.

See more details about this project

https://topophile.net/faire/la-ferme-des-possibles-ou-de-la-serendipite/http://materiauxreemploi.com/visite-de-chantier-resilience-la-ferme-des-possibles-a-stains/

https://www.bellastock.com/projets/resilience/?fbclid=IwAR35d8sy4CZpBAIg_0JgnOCIyFiO4h58VdCd2Y_MMwdxdmPRJwg8jogcLNk

Photo credit

Photo credit: Archipel Zéro

Contractor

Construction Manager

Stakeholders

Other consultancy agency

BELLASTOCK

Clara Bergia

https://www.bellastock.comAssistant MO Reuse

Company

Depuis 1920

Nathan Levinson

https://depuis1920.frMainly the realization of curtain facades in reused windows

Company

DALKIA FROID SOLUTION

Christian Rabin

https://www.dalkiafroidsolutions.comHVAC company, thermo-fridge-pump

Environmental consultancy

Réavie

Mohamed Hamaoui

http://asso-reavie.frSupply of reuse plumbing equipment

Company

Bois 2 Bout

Benoït de Bellefonds

http://www.bois2bout.frTimber frame, CLT floors, Installation of prefabricated wooden boxes with straw insulation (Ekobloks)

Company

AF Rénovation

Hakim Fernane

Carpentry-placo, supply and installation of re-use materials: interior double-glazed windows and cast iron radiators

A Coeur de Chaux

Georges Bodnar

http://www.acoeurdechaux.comLime-plaster renderings on exterior earth renderings

Company

Terraterre

Franck Lamy

http://www.terraterre-hautemarne.comImplementation of BTC bricks

Manufacturer

Rainbow Ecosystem

Raphael Petit

https://rainbowecosystem.com/fr/Realization of Ekobloks, prefabricated wooden boxes filled with compressed straw and coated on both sides with a raw earth plaster

Contracting method

Separate batches

Type of market

Global performance contract

Energy consumption

- 100,00 kWhep/m2.an

- 157,00 kWhep/m2.an

More information

Unknown to date. As the building has a large part of its premises refrigerated, and unheated buffer spaces, the RT 2012 calculation is unsuitable.

Systems

- Heat pump

- Water radiator

- No heating system

- Heat pump

- Reversible heat pump

- Others

- Free-cooling

- Single flow

- Double flow heat exchanger

- Heat pump

Urban environment

- 13 000,00 m2

- 7,00 %

- 10 500,00

Product

Dalkia froid solutions

https://www.dalkiafroidsolutions.com/HVAC, électricité / ventilation, cooling

Construction and exploitation costs

- 1 800,00 €

- 499 000,00 €

- 210 000 €

- 3 285 000 €

Reuse : same function or different function

- Structural works

- Structural framework

- Indoor joineries

- Outdoor joineries

- Partitions

- Electricity

- Heating ventilation air conditioning

- Plumbing

- Landscaping

- others...

Environmental assessment

- 69.22 tons eq CO2

- 763.3 m3 of water

- 88 tonnes of waste

Economic assessment

- 21 400 €

- 1 %

- 107 000 €