Industry 4.0 could be a key player in mitigating climate change

Industry emissions account for 30 per cent of total global greenhouse gas emissions. But, production processes are currently undergoing massive shifts due to digitalisation efforts, known as Industry 4.0 or IIOT (“Industrial Internet of Things”).

Journalist Christoph Behrens from Süddeutsche Zeitung met with the authors of our newest publication, Climate Innovation Insights, to discuss this topic on a panel at Productronica, the world’s biggest trade fair for electronics manufacturing.

A commentary by Maria Loloni, Sustainable Production Systems Expert at Climate-KIC.

Industry 4.0 and climate change are an unusual pair, but they have obvious things in common: They’re systemic, they’re complex, and they’ll disrupt how we as a society conceive of value creation.

While climate change will force us to think more and more about the ecological footprint of a product—to make sure that we produce and consume within environmental boundaries—IIOT, and the rise of interconnected AI-based machinery, will drastically change how we value (and interact with) human labour. The global competitive landscape is steadily shifting towards digitalisation of all activities and using big data analytics to raise cost efficiency, quality, and production speed.

But there’s a different potential of IIOT: Its contribution to establishing a circular economy and a greener industry. “Smart manufacturing” allows the gathering of data along the lifecycle of a material, understanding the material input, and considering the end-of-life of a material, instead of putting it to landfill,” says Sira Saccani, Director Sustainable Production Systems at Climate-KIC.

This can help establish production processes with zero per cent of extracted raw material, net-zero emissions, and 100 per cent recycling. This is necessary to keep products, materials, and components at a high level of a value, and multiple lifecycles—the foundation of a circular economy. She adds: “There will be a need for new product concepts where materials are available for high-quality recycling across different industries. Product designers are at the moment not trained to create this kind of product.”

As Industry 4.0 technologies are being implemented worldwide, we gradually build a virtual image of all production processes and entire supply chains. If there’s an open access channel for this data, skilled product designers will be able to tap into this information, giving them the possibility to integrate secondary materials from all different industries into their design process. That would be a whole new way of value creation.

DATA, DATA, DATA for climate innovation

As we have worked in a linear way for over 150 years, there are almost no interconnected value chains in the production industries at the moment—besides sales. It might take decades until IIOT technologies reach their full potential and provide circularity in the production industries.

But there are visionaries working on this in beacon projects right now. One of them is David Tronchoni, Founder of Edinn, an Industry 4.0 platform based in Spain that delivers real-time-information on losses in production processes: Material and energy consumption, quality, and speed issues as well as human failure. “When these losses are addressed, CO2 emissions can be lowered significantly”, says Tronchoni.

Key tools like this could become the new foundation of a circular production model. “To know exactly what and how much material is needed for every process enables the exchange of material between local and connected companies. The technology behind this is powerful and at the same time easy,” says Tronchoni.

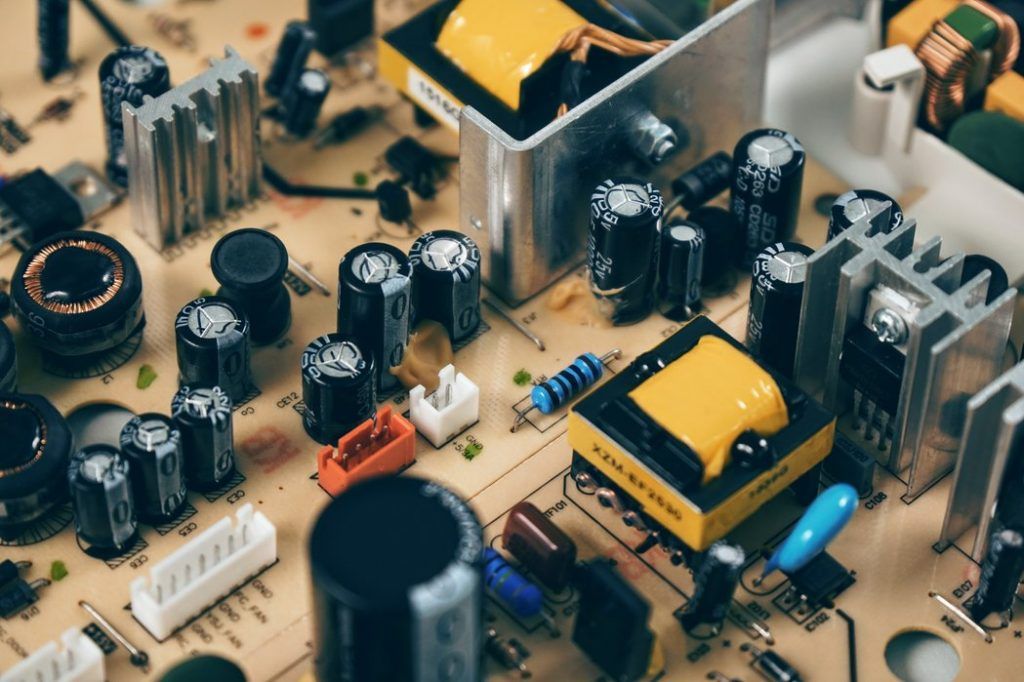

A new era for electronics production

“There are certain industries that will be forced to use IIOT for circularity earlier than others. The electronics industry is one of them. Its need for rare earths and emission-heavy metals will not be manageable by additional extraction soon. Especially in Europe, where we basically almost can’t mine raw materials needed for industrial activities,” says Prof. Dr. Alessandra Bonoli, a circular economy expert from the University of Bologna.

“The only mining option is the so-called urban mining, meaning, the recycling of electronic equipment in order to extract and recycle it as a secondary raw material,” he adds.

A highly efficient waste-management system in the electronics sector might become mandatory, to stop practices like shipping electronics waste to third world countries for down-cycling. These environmental issues have to be addressed on a factory level.

A chance for Europe

“The circular model is now mandatory. We have to move towards a low-carbon future,” says Bonoli. In that, there’s a big chance for the EU in promoting IIOT for climate innovation and circularity. In my opinion, Europe could showcase that it’s able to have an economy that works in a regenerative way, showing new ways of collaborating, and using open-source to create social value. Therefore, let’s have a mind shift and make this transformation a reality.

Feel inspired? Check out these nine case studies on Industry 4.0-based circularity: Climate Innovation Insights

News published on Daily Planet - Climate-KIC

Consult the source