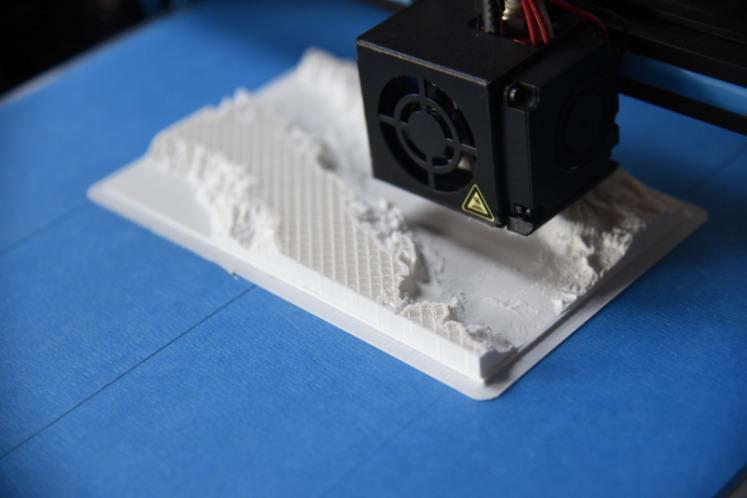

ETH Zurich combines 3D printing and casting to make more efficient concrete structures

Researchers at ETH Zurich have created a machine that controls the setting rate of concrete to offer a "seamless transition between casting and 3D printing" so that structures can be made that use less material.

The system called Fast Complexity combines two existing technologies for creating concrete forms – 3D printing concrete and casting into formwork.

It was developed by Ana Anton, Andrei Jipa, Benjamin Dillenburger from ETH Zurich's Digital Building Technologies group and Lex Reiter from its Physical Chemistry of Building Materials group.

By controlling the setting rate of concrete, the system can either 3D print the fast-hardening concrete for more structural elements without formwork or extrude a more fluid concrete that can flow into castings.

"The major innovation is the concrete 3D printing process developed by ETH Zurich," Anton told Dezeen. "Our material can be digitally controlled from a fluid concrete mix to a fast hardening concrete. In this way, we can have a seamless transition between casting and 3D printing."

The system could lead to a reduction in the amount of concrete used to create buildings as only the material that is needed would be poured or printed.

"Both the geometry of the slab and the deposition path are optimised to only add material where needed," said Anton. "Such geometries would be otherwise too expensive to fabricate." "That reduction is project-specific and depends on structural evaluation, but compared to a massive slab, there is a lot of space for material saving," she continued.

Read the full news here.

News published on Build Up News

Consult the source

Photo credit :Photo by Amin Hasani on Unsplash