LILAC: Low Impact Living Affordable Community

Last modified by the author on 31/01/2014 - 12:30

New Construction

- Building Type : Collective housing > 50m

- Construction Year : 2013

- Delivery year : 2013

- Address 1 - street : Lilac Grove, Victoria Park Ave LS5 3AG LEEDS, United Kingdom

- Climate zone : [Cfc] Marine Cool Winter & summer- Mild with no dry season.

- Net Floor Area : 1 676 m2

- Construction/refurbishment cost : 2 221 617 €

- Number of Dwelling : 20 Dwelling

- Cost/m2 : 1325.55 €/m2

-

Primary energy need

62.78 kWhpe/m2.year

(Calculation method : Primary energy needs )

LILAC is the UK's first affordable, ecological cohousing project. A community of 20 households and common house, the buildings are made with the ModCell prefabricated straw bale construction system, assembled by LILAC members using local straw. The excellent insulation properties of straw, combined with airtight construction, triple glazing, and heat recovery ventilation, reduce energy and CO2 emissions to a minimum. A community owned Solar Hot Water & Photovoltaic scheme reduces energy & CO2 emissions further. The site has a sustainable urban drainage system to minimise water use and run-off, and the landscape includes herb gardens and allotments shared with the wider community.

The LILAC homes have received UK Energy Performance Certification (EPC), according the SAP 2009 assessment procedure.

(Cost data includes the specific construction costs of the homes + fees & site preparation, excluding parking and urban sewerage).

Stakeholders

Developer

LILAC MHOS Ltd.

http://lilac.coop/Designer

White Design Associates Ltd.

http://white-design.com/Manufacturer

ModCell

http://www.modcell.com/Contractor

Lindum

http://lindumgroup.com/Thermal consultancy agency

ProGETIC SCP

http://progetic.com/index.php/en/Others

Co-Ho Ltd.

http://www.coho-ltd.co.uk/Structures calculist

Integral Engineering Design

http://integral-engineering.co.uk/Others

BWA Quantity Surveyor

http://bwa.uk.net/Contracting method

General Contractor

Type of market

Realization

Energy consumption

- 62,78 kWhpe/m2.year

- 200,00 kWhpe/m2.year

Envelope performance

- 0,19 W.m-2.K-1

- 2,75

More information

Billing data is currently being collected.

Real final energy consumption

104,95 kWhfe/m2.year

Systems

- Gas boiler

- Gas boiler

- Solar Thermal

- No cooling system

- Double flow heat exchanger

- Solar photovoltaic

- Solar Thermal

- 30,00 %

Urban environment

- 5 000,00 m2

- 16,00 %

- 1 000,00

Product

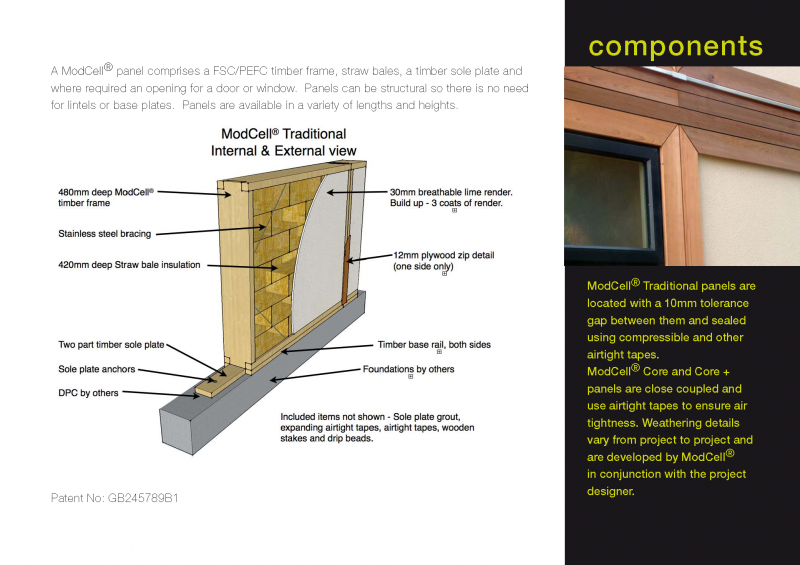

ModCell Traditional Panel

ModCell

http://www.modcell.com/Structural work / Passive system

ModCell® is one of the first products to make large-scale, carbon-negative building a commercial reality.

The ModCell® system utilises the excellent thermal insulation qualities of straw bale construction to form prefabricated panels, made in a local Flying Factory™.

ModCell® allows super-insulated, high-performance, low energy ‘passive’ buildings to be built using renewable, locally sourced, carbon sequestering materials that include straw bale and hemp to create a less than zero carbon construction system.

Construction and exploitation costs

- 4 251 338,00 €

- 38 471,00 €

Indoor Air quality

GHG emissions

- 10,60 KgCO2/m2/year

- 80,00 year(s)