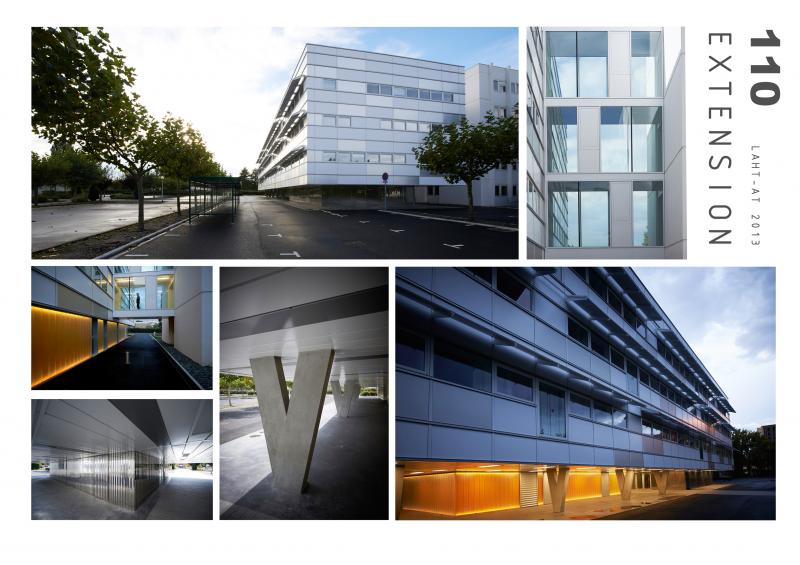

Office building CILSO / DOMOFRANCE

Last modified by the author on 27/08/2013 - 16:08

New Construction

- Building Type : Office building < 28m

- Construction Year : 2012

- Delivery year :

- Address 1 - street : 110 AVENUE DE LA JALLERE 33042 BORDEAUX, France

- Climate zone : [Csb] Coastal Mediterranean - Mild with cool, dry summer.

- Net Floor Area : 2 970 m2

- Construction/refurbishment cost : 4 083 500 €

- Number of Work station : 100 Work station

- Cost/m2 : 1374.92 €/m2

-

Primary energy need

42 kWhep/m2.an

(Calculation method : RT 2005 )

Through its various fields of activity, CILSO Group is strongly committed to and involved in social and environmental concerns. The proposed extension of the headquarters which was realized in 2008 , is in these values. The aim was both to consolidate all headquarters employees and respond to future project development group.

As of 2009, the choice was focused on achieving a positive energy building ( BEPOS ) that produces more energy than it consumes through bioclimatic design , minimizing the energy needs, and local production of electricity with photovoltaic panels. Construction performed and managed according to HQE ® has all the usual qualities of architecture, functionality, quality and use, while greatly minimizing the impact on the environment.

Particular attention was paid to the choice of building materials and the various facilities available to employees to ensure health and comfort.

50 additional parking spaces were created and 32 trees and 60 shrubs will be planted . One significant existing tree will be sacrificed . In addition to these parking spaces, some electric bikes will be available to the staff and a pool of electric vehicles.

All offices are naturally lit : the nuclei of movement, health and service spaces are clustered in the center of the building. The walls of offices overlooking the circulations are partially glazed to allow light in their second day.

A guide has been written to give explanations to employees on the operation of the new building and the actions to take.

A GTC can finely control equipment to ensure user comfort and control energy consumption. Monitoring and optimization of actual performance will be carried out on a minimum of 2 years by an external provider .

Sustainable development approach of the project owner

The building is part of a high environmental quality with an exceptional level target 5 in very high-performance, 8 performance level. The choice of materials and the ventilation system have been given special attention to ensure good indoor air quality. System allows rainwater to meet the needs of water for health. The local electric power is provided by a roof and solar shading (700 m²)Architectural description

This building has been a bioclimatic design with a North / South orientation. Compactness, high insulation of the casing with a low air permeability and a double flow ventilation system with energy recovery are used to reduce the need for heating and raffraîchissement strongly.Building users opinion

Occupants enjoy acoustic comfort, thermal and visual. It took time to adapt to tame the equipment provided (lights dimming, heating programming ...).

They appreciate being able to keep hold of their work environment despite the systems in place to maximize comfort and performance: ability to open windows when there is a double flow system, turn off / turn on the lights so that there is an automatic light dimming and presence detection ...

If you had to do it again?

This kind of project is very educational and inevitably some topics wouldn't be exactly treated the same way today. The industry is evolving and designers gradually rise in competence in these areas.

No recipe or regrets, but in a few words: the study phases are important, a strong presence on the site is required, performance requires going into detail but should not forget the simple, common sense and finally, the end customer, which should be a central concern.

See more details about this project

http://www.construction21.eu/france/data/sources/users/328/docs/cilso-guide-extension-siege-social-v27-03-2013.pdfStakeholders

Contractor

Cilso

Moreau Stéphane (05 56 43 62 60)

http://www.cilso.frAssistance to the Contracting Authority

BMA

DAVRIL Joël (05 56 99 31 99)

http://www.b-m-a.frContractor

Domofrance

Moreau Stéphane

http://www.domofrance.frConstruction Manager

Agence Alain Triaud & Luc Arsene-Henry

Triaud Alain (05 56 69 35 10)

Other consultancy agency

EGIS

Plichon Sébastien (05 56 11 90 00)

http://www.egis.frContracting method

General Contractor

Type of market

Realization

Energy consumption

- 42,00 kWhep/m2.an

- 120,00 kWhep/m2.an

Real final energy consumption

54,00 kWhef/m2.an

Envelope performance

- 0,26 W.m-2.K-1

- 0,59

More information

Le Maître d'ouvrage est conscient que les résultats issus du moteur de calcul RT 2005 ne permettent pas d'estimer les consommations réelles. Des simulations thermiques dynamiques ont donc été réalisées en parallèle pour les approcher ainsi que pour optimiser le confort d'été. Un gros travail a été fait sur le choix et le fonctionnement des différents équipements afin de délivrer l’énergie strictement nécessaire avec réactivité en fonction des besoins réels et qu'un bureau inoccupé ne consomme pas d'énergie. Le choix du matériel informatique, la mise en place de pool impression... ont pour objectif de limiter les consommations des usages non pris en compte par la RT 2005.Le bâtiment est équipé d'une GTC permettant de piloter finement l'ensemble des équipements et de suivre les conditions de confort, les consommations par poste. Une mission spécifique de 2 ans a été confiée à l'ALEC pour vérifier les performances réelles du bâtiment.

Systems

- Heat pump

- Fan coil

- Other hot water system

- Reversible heat pump

- Fan coil

- Nocturnal Over ventilation

- Double flow heat exchanger

- Solar photovoltaic

Smart Building

Urban environment

- 43 770,00 m2

- 7,00 %

Product

Water management

- 290,00 m3

Indoor Air quality

GHG emissions

- 50,00 année(s)