LUCIA (Lanzadera Universitaria de Centros de Investigación Aplicada)

Last modified by the author on 29/04/2016 - 09:57

New Construction

- Building Type : School, college, university

- Construction Year : 2013

- Delivery year : 2014

- Address 1 - street : Campus Miguel Delibes 47011 VALLADOLID, España

- Climate zone : [Csa] Interior Mediterranean - Mild with dry, hot summer.

- Net Floor Area : 5 356 m2

- Construction/refurbishment cost : 7 253 461 €

- Number of Pupil : 177 Pupil

- Cost/m2 : 1354.27 €/m2

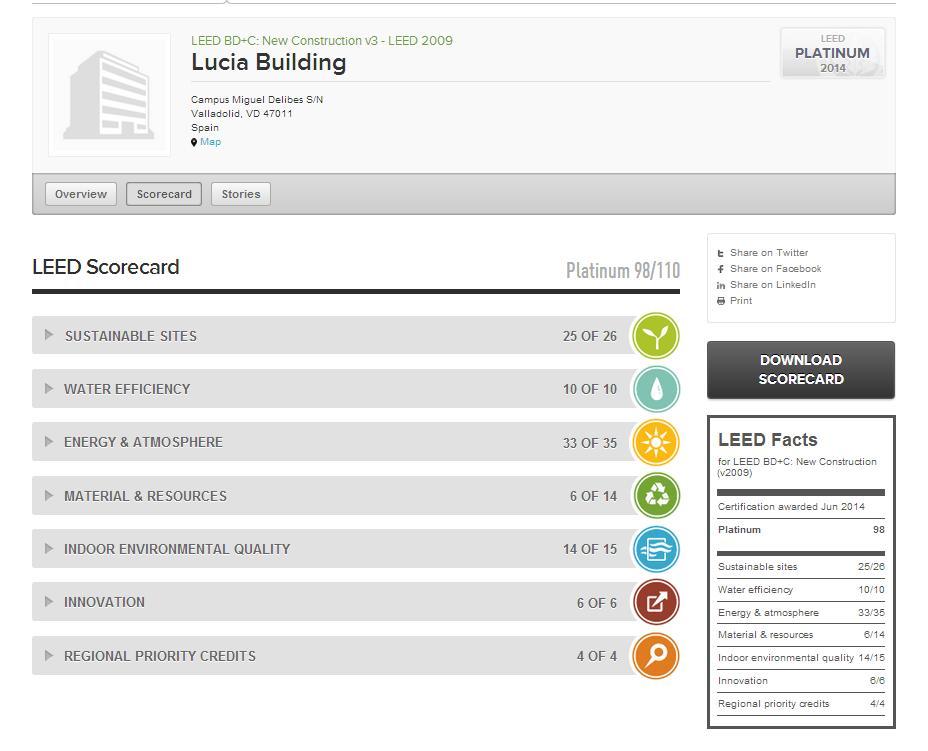

Certifications :

-

Primary energy need

285 kWhpe/m2.year

(Calculation method : Primary energy needs )

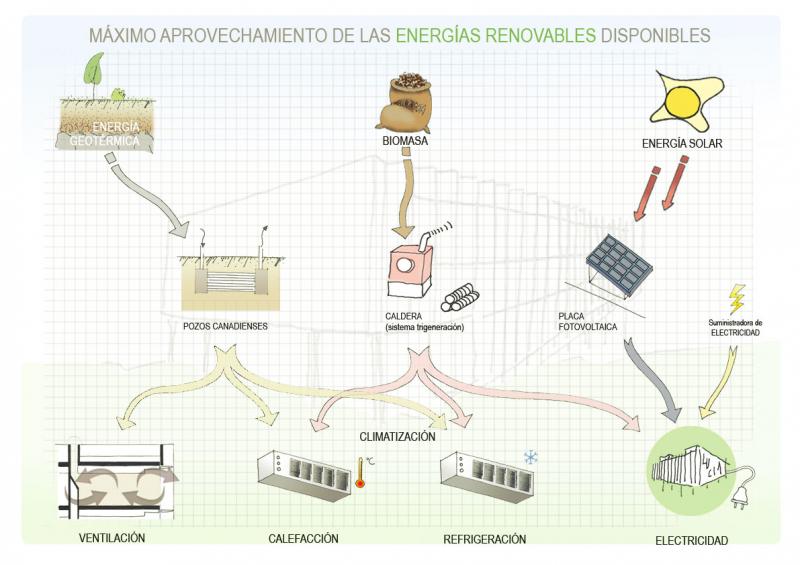

The LUCIA building of the University of Valladolid, ZERO CO2 emissions and ZERO ENERGY building, will house scientific centres and related work modules. It shows strategies in bioclimatic design to reduce energy demand in maintenance and use only renewable energies (biomass, photovoltaic and geothermal). Waste and water management, and social aspects have been taken into consideration. The building has been simulated with E-Quest tool, and evaluated using the LEED method, and VERDE Tool, with a view to obtaining the highest possible rating and a successful result s in economic, saving energy and zero CO2.

Architects: Francisco Valbuena García and the team of the Unidad Técnica of Architecture, of the University of Valladolid.

Funding: Junta de Castilla y León (Programme of Infrastructure of Research and Technological Development 2010-2012), and the European Regional Development Fund.

It will provide the springboard for research into social aspects of building sustainability, and it will constitute a prototype on which to test the bases for environmental methods and assessment for buildings. The LUCIA building will offer a model for conducting research into areas that will shed light on other as yet unexplored methods. It will use biomass, a surplus resource in the region where the building is being constructed, which has a major socio-economic impact, and will lead not only to job creation but also to enhanced self-sufficiency in energy.

See more details about this project

http://www.gbce.es/es/edificio/lanzadera-universitaria-de-centros-de-investigacion-aplicadahttp://www.construction21.org/articles/fr/net-zero-energy-buildings-winner-2015-lucia-spain.html

Data reliability

3rd part certified

Stakeholders

Designer

Francisco Valbuena García y equipo

Unidad Técnica de Arquitectura de la Universidad de Valladolid

http://edificio-lucia.blogspot.com.es/Developer

Vicerrecotorado de Patrimonio e Infraestructuras de la Universidad de Valladolid

Unidad Técnica de Arquitectura de la Universidad de Valladolid

http://edificio-lucia.blogspot.com.es/, http://www.uva.es/portal/paginas/portadaOther consultancy agency

Torre de Comares Arquitectos sl

María Jesús González Díaz

Contractor

CONSTRUCTORA SAN JOSÉ,S.A. - CYM YAÑEZ,S.A., UNIÓN TEMPORAL DE EMPRESAS (UTE EDIFICIO LUCIA)

José Luis Fernández Álvarez

Others

Instituto de la Construcción de Castilla y León ICCL

Beatriz Castrillo

http://www.iccl.es/Certification company

VEGA Ingeniería

Rafael Díaz Vega / Borja Román

http://www.vegaingenieria.com/Manufacturer

CIDAUT-Fundación para la Investigación y Desarrollo en Transporte y Energía.

Alfonso Horrillo Guemes

http://www.cidaut.es/Other consultancy agency

Pich-Aguilera Arquitectos

Pau Casaldáliga

http://www.picharchitects.com/Certification company

Kema Energy

Andrea Traber

Construction company

Siemmens

Owner approach of sustainability

The University of Valladolid considers the erection of this building as an opportunity to develop a sustainable building and to conduct research into sustainability. The building will provide the springboard for research, incorporation of new solutions, and control and verification existing methods of building sustainability. It will constitute a prototype on which to test the bases for environmental methods and assessment for buildings.

Architectural description

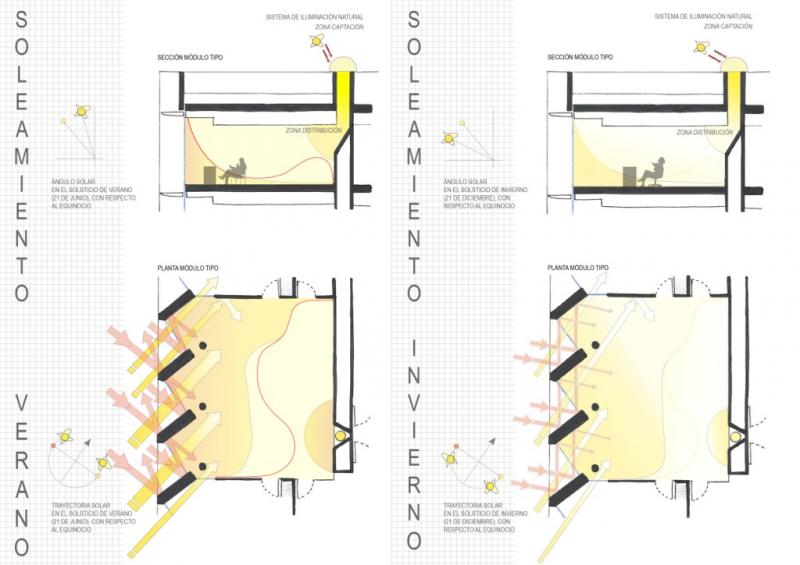

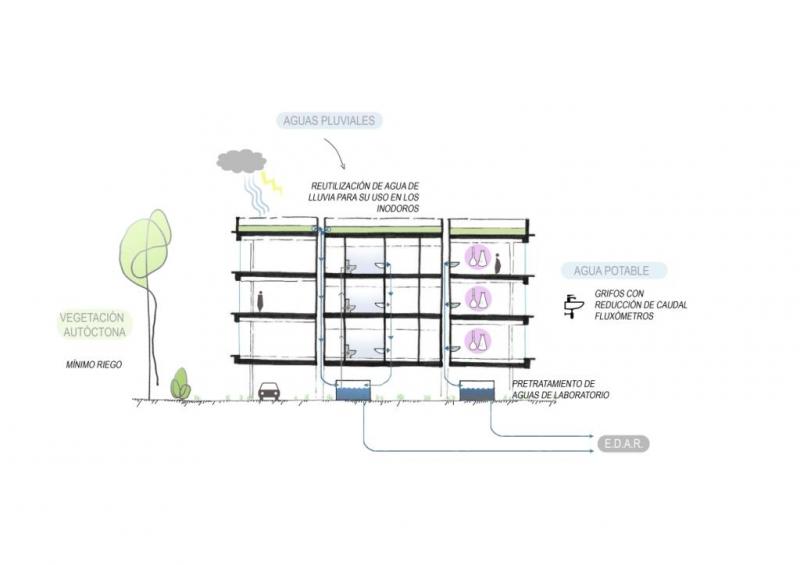

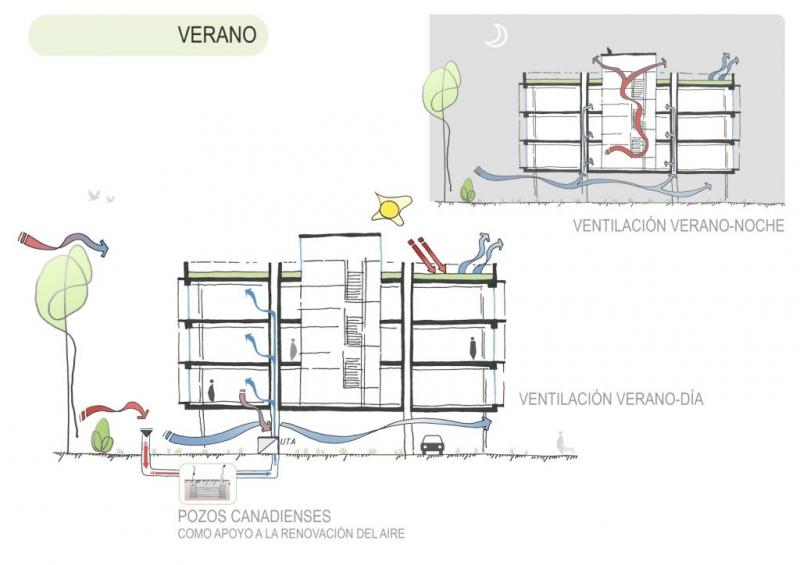

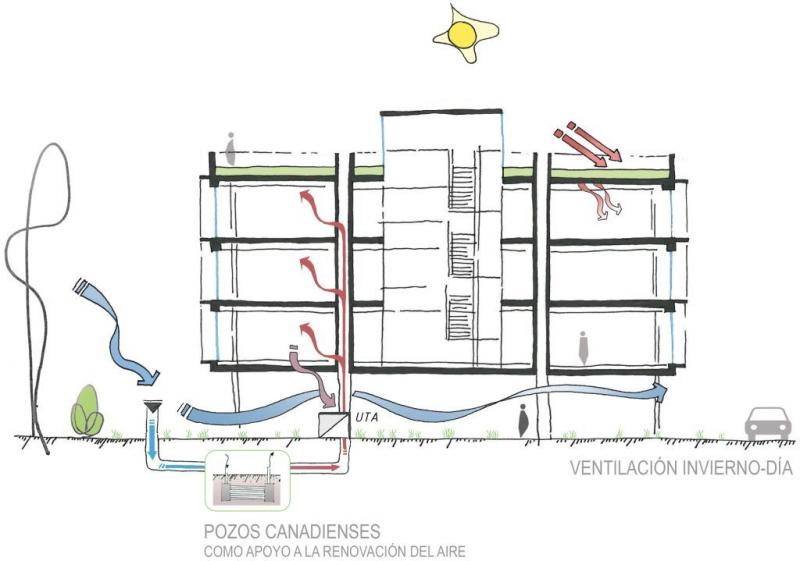

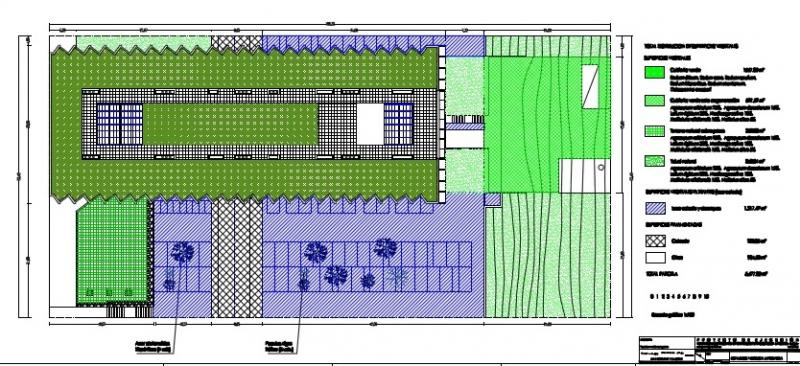

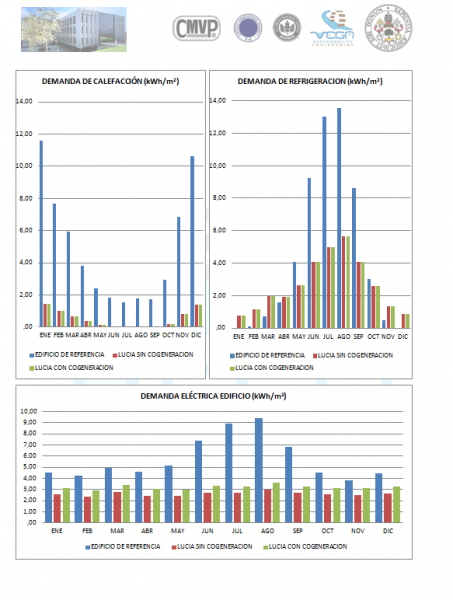

To sum up, the building will provide the springboard for research into Sustainable architecture and shows that it is possible using only renewable energies. We have found that energy self-sufficiency with biomass resource would be economically and technically feasible. The keys to achieving this are based primarily on bioclimatic design for energy saving, and finally using only renewable energies. It will constitute a prototype on which to test the bases for environmental methods and assessment for buildings, with important strategies aimed at simultaneously and no merely energetically: (water, waste, construction materials, social aspects of building sustainability, training and educational actions about awareness and environmental consciousness, etc). The bioclimatic strategies are: Compactness: One of the Bioclimatic strategies is the compactness of the building. The building has a 0.37m-1 form factor for its 5,920m2 of usable space, giving a ratio which is hard to improve. Compactness means the relation between surface and envelope and the climate controlled area can be optimized, thereby reducing the former. Form façade design: The characteristics of the site require long walls facing south-west and north-east. This meant that a careful re-orientation study was performed when designing the spaces combined with the eaves in the parts facing the sun. Using this system, 89% of the surface openings face south and east, achieving thermal gains in winter, and a self-shadowing effect in summer, thereby reducing the cooling load, whilst at the same time ensuring natural light. On its longest sides, the resulting surface resembles a “saw-tooth”, one drawback being the increased surface envelope. This disadvantage is offset by the design, which leads to a 24% reduction in the building’s cooling loads, according to the simulations carried out. Insulation: The thermal transfer coefficients used in the building envelope compared to those stipulated by Spanish Building Regulations (CTE) and ASHRAE (ASHRAE 2007) are really important: The insulation coefficients used, a key factor (U=0.17 W/m2K on facades, and U= 0.15 W/m2K on the vegetation canopy) will restrict loss through transfer and therefore lead to a reduction in demand. One drawback is the increased energy in the materials that can be reduced or even removed through the use of natural insulation (100% natural from wood), and an extra financial cost which is offset by the reduction in energy consumption. One further aspect to be taken into account in this section is the effect of thermal inertia achieved in the structure of the building itself (reinforced concrete), particularly with the green roof, which covers 73.5% of its surface. Natural Lighting using solar tubes: The decision to construct a compact building has been merged with an increase in natural lighting of indoor areas through the widespread use of tubular day lighting devices or solar-tubes (27 in all) and skylights above the staircases. In addition to offering beneficial effects for health and wellbeing, natural light reduces the electricity requirement for artificial light. The system affords a number of excellent benefits: these are static elements which simply reflect incident sunlight, as a result of which they require no power to work. Other strategy is the DALI control system (Digital Addressable Lighting Interface) to control lighting in the building. As an additional means of saving energy, the enthalpic energy recovery ventilators s use more than 60 % of the expelled energy by the ventilation system. Geothermal pipes on the site to support the pre-acclimatization of the air to ventilation system, combined with the enthalpic energy recovery ventilators. Light heat island effect: Reducing the heat island effect at the site and creating a microclimate is achieved through the use of permeable surfaces with filtered pavement located outside the building; sedum type intensive vegetation canopy covering 73.5% of the surface; local vegetation and deciduous trees at the site as well as other features that help create microclimates. Construction materials: Use of low-environmental impact construction materials (low embodied energy and no-VOC); recycled end renewal construction materials. Waste: A further aspect taken into consideration is waste management during the construction phase as well as during the building's use. The project includes a plan for studying all the waste generated during the building’s life-cycle, and the creation of compost from vegetable waste is also envisaged. Finally, the waste generated during future demolition of the building has also been studied with a view to securing the maximum possible recovery of the materials used. Water: Rain water system (75% of the roof will be green roof), and 100% of the grey water will be subject to a recycling process. Training programmes: Those initiatives will be combined with awareness campaigning and educational and training programmes for the stakeholders, users and other people for the building sector, about bioclimatic aspects and energy items. The building has been evaluated using the E-Quest tool; LEED method, with a view to obtaining the LEED-NC PLATINUM; VERDE Tool (more than 4 over 5 leaves) with excellent results in economical, saving energy and Zero CO2 areas.

If you had to do it again?

Some of the previous items from the Project has been reinforced and another one must be checked after the experience:

-The importance of architectural aims, such as forms, volumes, and bioclimatic design, before technical ones.

-The support of all the stakeholders (promoters, architects, constructor, staff, users, manufactures, etc) and de environmental consciousness of all of them

-Regulations must facilitate this kind of architecture. Strategies and innovative methods going on faster than regulations.

-In this climate region, cooling items are more important and difficult to solve than heating items.

Energy consumption

- 285,00 kWhpe/m2.year

- 339,00 kWhpe/m2.year

- 81,82 kWhfe/m2.year

Envelope performance

- 0,17 W.m-2.K-1

- 0,37

- 3,00

Systems

- Combined Heat and Power

- Other hot water system

- Trigeneration

- Free-cooling

- Solar photovoltaic

- Biomass boiler

- Other, specify

- 100,00 %

Smart Building

GHG emissions

- -5,00 KgCO2/m2/year

- 7,92 KgCO2 /m2

- 50,00 year(s)

Life Cycle Analysis

- 55 092,00 kWhEP

Water management

- 0,65 m3

- 684,00 m3

- 694,00 m3

Indoor Air quality

Comfort

Product

Geothermal pipes, called Canadian wells or geothermal tubes as well.

El sistema se construye en obra y se ha realizado con tubos de polipropileno reforzado REHAU

_

_

The building has a geothermal pipes system, combined with the enthalpic energy recovery ventilators to support the ventilation system, to implement the requirements of CTE Spanish regulations CTE.

This system, which prepares outdoor air conditions naturally before ducting it into the ventilation system, may be deemed both a bioclimatic as well as renewable energy production device. It will provide the power equivalent of 25,000 hWh. The drawback is the over economic cost, balanced by the energy saved.

The acceptance of the innovation of the building will be determinate after to check the advantages.

SOLATUBE Daylighting system

_TECLUSOL SOLATUBE

_

They are high-performance daylighting systems that use advanced optics to significantly improve the way daylight is harnessed. These are static elements which simply reflect incident sunlight, as a result of which they require no power to work. According to the simulation carried out, the annual 146,190 kWh lighting that would be needed by the reference building (ASHRAE standards) would be cut to 74,790 kWh in the LUCIA building (approximately half) thanks to these devices. The cost of these 27 devices was calculated in the project estimate to be around 13,483 €.

The system affords a number of excellent benefits, which the energetically simulation shows. The final results will be checked when this building will then be occupied. Until now, the day lighting improves markedly.

Photo-catalytic materials

_

_

_

Photo-catalytic materials for cleaning air and to reduce the NOx in external ceramic walls of the roof, and photo-catalytic paintings over prefabricated concrete panels of façade. The Photo-catalytic process is a reactor for the destruction of NOx pollutant in an air current.

The building, when complete, will be checked to confirm that satisfies all requirements and effectiveness of NOx reduction.

PHOTOVOLTAIC DOUBLE SKIN

productor de la fotovoltaica ONYX SOLAR e informe realizado por el estudio de Pich-Aguilera arioqtectos.

_

_

The architectural design of the building merges photovoltaic systems in two ideal areas: the double skin curtain wall in the south-east facing wall (where common rest areas are located) and two skylights above each of the staircase areas. The actual photovoltaic panels themselves and the double skin allow this strong natural light to be filtered into the building’s interior. The double skin facade produces 5,000 kWh per year and the skylights 5,500 kWh, leading to an annual saving of 3,570.00 euros. They contribute to the building’s positive renewable energy balance as well as encouraging research into the topic such that, in addition to producing electrical energy, the skylights aid climate control in the building, both in winter and summer. This entails an added cost in financial terms which is offset by the constant reduction in energy consumption, further research, and emission reduction.

Construction and exploitation costs

- 7 046 350,00 €

- 10 572 800,00 €

- 138 500,00 €

Energy bill

- 11 840,00 €

Urban environment

The building is located in the University Campus form Valladolid, in a specific site. According to LEED certification, the building: - is located in a place with development density and community connectivity - No damage to original biodiversity - Connectivity to more than 10 urban facilities near to 800 m, and local density to 10 dwellings /4000 m2 in the area. -Pedestrian connectivity to urban facilities - Rail station proximity: The building is located within 800m walking distance to rail station. - High proportion of native or adapted vegetation compared to total site area (the building footprint). High proportion of green roof.

Land plot area

5 677,00 m2

Built-up area

37,00 %

Green space

3 182,00

Parking spaces

Open-plan car park design:

In addition to the personal benefits (an open-plan car park is far more pleasant than a closed one), taking such a decision allows for natural ventilation and lighting, drastically reducing the need for artificial lighting, fire-fighting facilities, anti-CO2 equipment, and so on. The drawback is the reduced possibility of averting theft.

The LUCIA building provides secure bicycle racks of a building entrance.

It provides preferred parking to disability people, electric and hybrid car, car sharing, modal shifts from more energy-consuming modes of transport to less energy-consuming ones, etc. The size parking capacity to meet but not exceed minimum local zoning requirements.